| Model: | PTC Anode |

|---|---|

| Brand: | PTC |

| Origin: | Made In India |

| Category: | Industrial Supplies / Other Industrial Supplies |

| Label: | Titanium MMO Anodes , Platinized TitAnode , Electrochlorinator |

| Price: |

US $250

/ pc

|

| Min. Order: | 1 pc |

Product Description

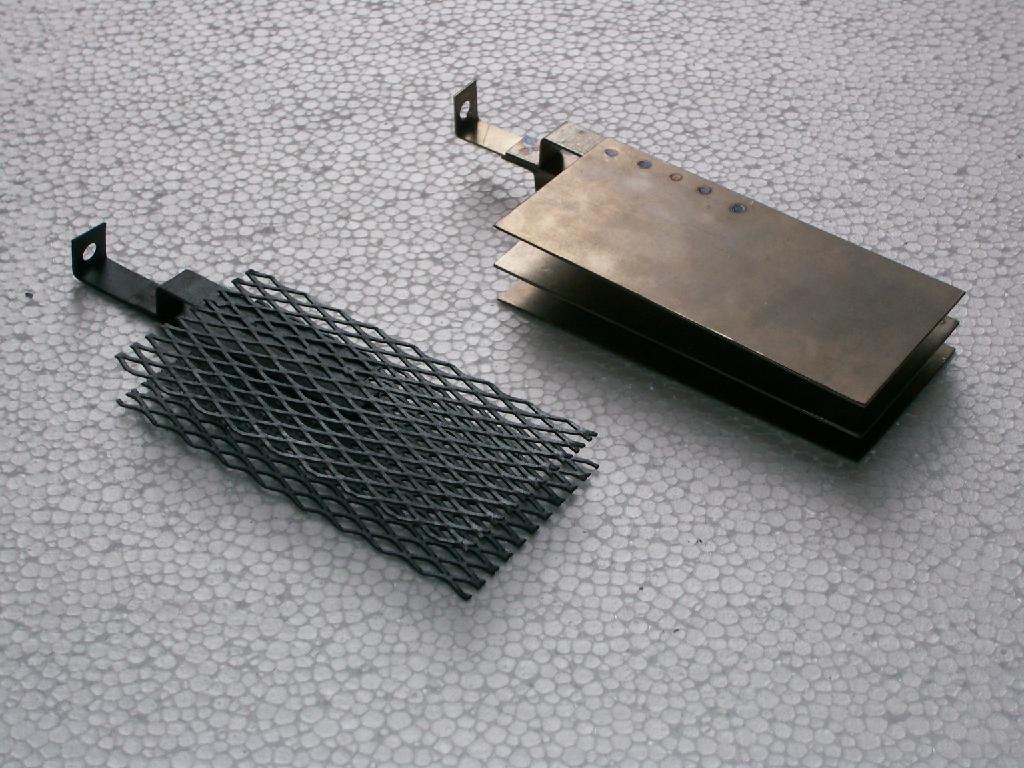

ELECTRODES (ANODES)

Mixed Metal Oxides (MMO) Anodes and Platinized Anodes

Perfect Titanium Components (PTC) is a customer oriented and technology driven company. The majority of our Anode products are based on our customer needs and tailor made Anodes. Our products to meet their specific applications and their needs.

We are a supplier of different type of Anodes as

# Titanium MMO Anodes

# Titanium Triple Oxide Anodes

# Platinized Titanium Anodes

# Platinized Niobium Anodes

Those Anodes are used for

*Impressed Current Cathodic Protection (ICCP)

*Water and wastewater treatment

*De-colorization of water

*Electrochlorination Cells for Brine water and Sea water electrolysis

*The production of Chlorine and Hypo Chlorine

*Metal finishing and metal winning process.

*Electroplating Industries

*Electrosynthesis

*Environment

*The refurbishment and replacement of Electrochlorination Cells

Our PTC Anodes are made out of Base metal (substrate) Titanium and Niobium based with an active precious metal Coating & Plating.

Our PTC Anodes are available in the form of

Ø Sheet

Ø Mesh

Ø Rod

Ø Tube

Ø Strip

Ø Ribbon

Ø And Custom-made

Quality:

We are a supplier of the said Anodes as per customer request and in standard

sizes. The production of our Anodes process are to make sure the specifications are will be covered the code of ASME, ASTM, DIN, BS, as per ISO 9000, etc,.

Mixed Metal Oxides (MMO)Anodes

Our Anodes are using for different applications and Industries. The Anode is based on Titanium (Substrate) and Niobium (Substrate) coated with an active precious Mixed Metal Oxides like Ruthenium, Iridium, etc., in different ratio as per the applications. The special Coating activates the Anode and provides excellent electrolytic properties. For an example: Comparing with conventional impressed current Anodes, the Anodes are small, lightweight and extreme low consumption of power rate of less than 1.Omg/amp yr.

Our MMO Titanium Anodes perform well in all types of Environment including areas with extremely low pH level (under 1), and high Chloride concentration. Their unique configuration makes the Anodes ideal for use in a wide variety such as Cathodic Protection system for buried structures, pipe line, steel in concrete, ship, jetties and wharf.

MMO Coating & Current Output:

Our MMO coatings greatly prolong the life of the Anode (low wear rate) and provide excellent resistance such as acid condition. However, coating loading may be adjusted to suit a particular current density or design life.

Our MMO Anodes are available in most different shapes, forms, sizes and lengths. For an example: the following listed are few commonly used Anodes for Cathodic Protection with maximum rated output current.

Substrate (Base Metal) : Titanium and Niobium

Coating or Plating Materials: Ruthenium, Iridium, Titanium and Platinum

Forms : Sheet, Mesh, Rod, Tube, Strip, Ribbon and Custom made.

Type of coating :

Ø Mixed Metal Oxide coating

Ø Triple Oxides coating

Ø Repair and Refurbishment of used Anodes

Ø Recoat, Refurbishment, Assembly and Replacement of Brine Water & Sea Water Electrochlorination Cells

Application Fields:

• Titanium Anodes for Copper foil production

• Titanium Anodes for Chlor Alkali Cells

• Titanium Anodes for Chlorine Dioxide Cell

• Titanium Anodes for Caustic Potash

• Titanium Anodes for Water Electrolysis

• Titanium Anodes for Sewage Treatment

• Titanium Anodes for Cathodic Protection

Advantagesfor above said Anodes are

• When activated coating is passivated, it can be coated again and use Repeatedly.

• Economical energy.

• Low weight.

• High dimensional stability and load resistance.

• Highly suitable as auxiliary anodes of complex geometrical shapes.

ManufacturingRange

• Box type •Rod type •Wire type •Ring Type •Plate Type •Mesh Type •Ribbon Type •Tubular Type •Runner Type •Any other Geometry

Our (PTC) MMO coated Titanium Anodes are also used in the following industries,

*Impressed Current Cathodic Protection (ICCP) MMO coated Titanium Sheet Anode, Tubular Anode, Ribbon Anode, Wire Anode, Rod Anode Disc Anode and Mesh Anode are available in most different shapes, forms, sizes and lengths as per customer request.

*Water and wastewater treatment MMO coated Titanium Sheet Anode, Tubular Anode, Rod Anode and Mesh Anode are available in most different shapes, forms, sizes and lengths as per customer request.

*De colorization of water MMO coated Titanium Sheet Anode, Tubular Anode, Rod Anode and Mesh Anode are available in most different shapes, forms, sizes and lengths as per customer request.

*Electrochlorination Cells for Brine water and Sea water electrolysis MMO coated Titanium Sheet Anode, Tubular Anode, Rod Anode and Mesh Anode are available in most different shapes, forms, sizes and lengths as per customer request.

*The production of Chlorine and Hypo Chlorine MMO coated Titanium Sheet Anode, Tubular Anode, Rod Anode and Mesh Anode are available in most different shapes, , forms, sizes and lengths as per customer request.

*Metal winning process MMO coated Titanium Sheet Anode, Tubular Anode, Rod Anode and Mesh Anode are available in most different shapes, forms, sizes and lengths as per customer request.

*Environment MMO coated Titanium Sheet Anode, Tubular Anode, Rod Anode and Mesh Anode are available in most different shapes, forms, sizes and lengths as per

customer request.

*Repair and Refurbishment and replacement of Anodes.

Platinized Anode

Platinum is having very good Physical and Chemical properties such as high corrosion resistance, good Thermal Conductivity and very good Catalytic nature. But it is expensive material and cannot be used in its solid form as an Anode. Because of high cost as in solid form, so by Electroplating process a thin layer of Platinum over a high corrosion resistance substrate. Titanium and Niobium are having very good Mechanical stability and uniform current distribution property.

So by coating Platinum on a specially treated Titanium and Niobium Substrate by means of Electrodepositing (Plating) process. Our (PTC) Platinized Titanium and Niobium Anodes are economical and retain the superior Physical and Chemical properties of Platinum.

Our (PTC) product ranges of Anodes are available in Sheet, Mesh, Plate, Wire, Rod, Tube and as per customer design and request.

Platinum Coating thickness– Minimum 0.5micron thickness

Maximum 15.0micron thickness

Specification :

Platinized Titanium Anode

PLATINIZED TITANIUM PLATE ANODE

PLATINIZED TITANIUM MESH ANODE

PLATINIZED TITANIUM TUBULR ANODE

PLATINIZED TITANIUM WIRE & ROD ANODE

PLATINIZED TITANIUM DISK & STRIP ANODE

Platinized Titanium Anode is an absolutely vital element for wet electro deposition of precious metals like Gold, Rhodium, Platinum, Palladium and nonferrous metals like Chromium, Nickel, Copper and Zinc. The p H level is 1.0 – 11.0,allowable Fluoride content is Maximum 50mg/l and allowable current is 50A/dm2. We offer Platinized Titanium Anodes in any size in the maximum of 1.2 sq.mtr.(0.6 metre X 2.0 metre) in single piece. Titanium plate, mesh, wire, rod and Niobium, Tantalum can also be platinized for various applications. We can do the coating thickness from 0.5 micron to 15.0 micron as per customer application and request.

Platinized Niobium Anode

PLATINIZED NIOBIUM SHEET and PLATE ANODE

PLATINIZED NIOBIUM MESH ANODE

PLATINIZED NIOBIUM TUBULR ANODE

PLATINIZED NIOBIUM WIRE & ROD ANODE

PLATINIZED NIOBIUM STRIP ANODE

Since the Niobium substrate is resistant to corrosion, the anode remains dimensionally stable over its operating life and consumption of the Platinum costing is extremely low (40 to 80 mg / amp-yr.). Because of its low consumption rate, the anode may be employed in a protection system to achieve a design life of 6 years and above. The p H level is 1.0 – 10.0, allowable Fluoride content is Maximum 100mg/l and allowable current is 100A/dm2. The anode is also Very light weight, flexible and strong. Platinized Niobium Anodes are designed for use in all types of aqueous storage and process equipment. The anode has proven to operate effectively in fresh, brackish and salt water and is not adversely affected by Chloride concentration.

Application :

Electroplating, Cathodic protection, Electrodialysis, Electrowinning process, Electrolytic production of Sodium Hypochlorite, Seawater application, Water and Waste Water treatment.

Quality :

We are a supplier of Anodes as per customer request and are in standard

sizes. The production of our Anodes process are to make sure the specification are will be covered the code of ASME, ASTM, DIN, BS, as per ISO 9000, etc,.

Member Information

| Perfect Titanium Components | |

|---|---|

| Country/Region: | India |

| Business Nature: | Manufacturer |

| Phone: | 9445891272 |

| Contact: | Nagarajan (Manager) |

| Last Online: | 27 Nov, 2013 |

Related Products of this Company

-

Titanium Heating and Cooling Coil

US $300

-

Electrochlrinator Cell

US $200