| Model: | DS-800A |

|---|---|

| Brand: | Wisdomshow |

| Origin: | Made In China |

| Category: | Industrial Supplies / Machinery / Welding Machinery |

| Label: | full automatic machi , bga rework station , youtube video bga |

| Price: |

US $16666

/ pcs

|

| Min. Order: | 1 pcs |

Product Description

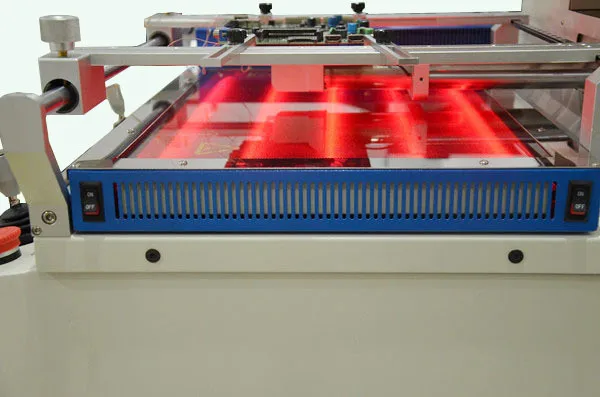

bga reballing video youtube DS-800A full automatic BGA rework station

DS-800A Specification 1(Super automatic ):

1, Full automatic,full optical alignment system

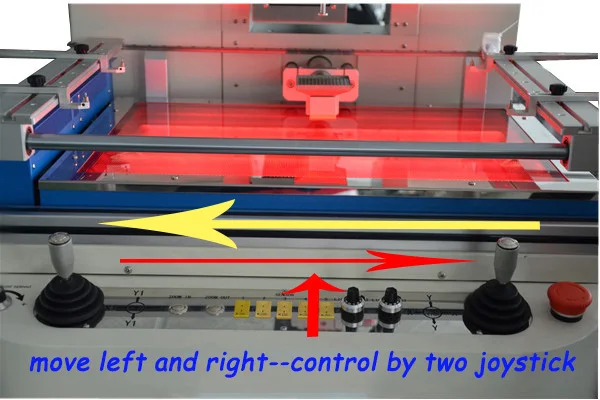

2, X,Y axis controlled by motor automatic move freely

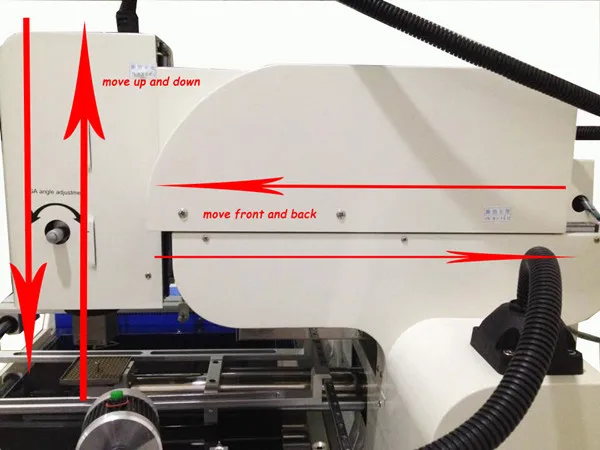

3, Lower heater move up & down,auto-controlled by motors(means you don't need to move PCB,only adjust the upper and lower heater to move towards target BGA ,very flexible.)

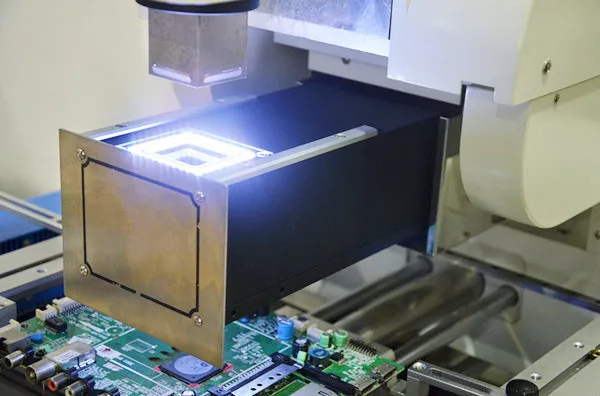

4, Color High-resolution optical vision system

5, Super preheating area,no repair dead area

6, Double rocker control the camera and upper and lower heating platform to make sure alignment precision accuracy

7, Applicable bga chips:laptop,mobile phone,ipad,macbook,game consoles,car motherboard ,medical equipment motherboard,shielding device repairing,video games chips,ps2/3/4,xbox360,double BGA/CGA/IC,CPU,GPU,plcc,ECU...

You can see detailed picture:

What's the Full Specification of full automatic BGA rework station DS-800A?

1.Hot air head and mounting head integration design, with auto soldering and desoldering functions. Full auto BGA repair machine

2.Upper heaters adopt hot air system,heating faster,temperature evenness,cooling faster.(the temperature can be up to 50 to 80 centigrade)It can better meet technological requirements about lead-free

soldering.Lower heaters adopt Hot air & IR mix heating. IR acts on the heating area directly; in the meanwhile, hot air works. They interact to heat quickly, and keep temperature even. (heating-up speed is up to 10 centigrade per

minute.automatic bga rework station

3.Independent 3 heaters, upper and lower heaters can realize move synchronously and automatically,can reach IR every position.Lower heater zone can remove up and down,support PCB board. bottom pre-heating

area along X/Y axis. Lower heater can move up/down and support PCB,auto-controlled by motors.

It can realize the upper and lower heater able to move towards target BGA, without moving PCB. Full auto BGA repair machine

4.PCB board adopts high accuracy slider to make sure the mount precision of BGA and PCB.

Unique bottom preheating table made of Germany-imported good quality heating materials plated IR

tube & constant temperature glass anti-dazzle (heat-resist up to 1800 C), pre-heating area up to 500*420mm.

Preheating table, clamping device and cooling system can move integrally in X axis that make PCB locating &

desoldering safer and conveniently.

7.X and Y axis adopt motor automatic control moving way to make the alignment faster and more convenient,make

the most use of the equipment space,realization of repairing large area PCB with a smaller volume of equipment.

The Max.plate size can reach 650*610mm,no repair dead corner.

8.Double rocker control the camera and upper and lower heating platform to make sure the alignment precision

accuracy.

9.Inbuilt vacuum pump, rotate 360 in angel; fine-adjusting mounting suction nozzle. BGA repair notebook machine

10.Suction nozzle can detect BGA pickup and mounting height automatically with pressure controllable within 10

grams;zero pressure available to smaller BGA pickup and mounting.automatic bga rework station

11.Color high-resolution optical vision system, movable by hand in X/Y axis, with split vision, zoom in and fine-adjusting functions, aberration distinguish device included, auto-focus, software operation, 22x optical zoom;

reworkable max. BGA size 80*80MM;

12.With 10 segments of temperature up (down) and 10 segments of constant temperature control,can save many

segments of temperature.analyze the temperature parameter curves on the touch screen.

13.Many sizes of alloy nozzle, easy for replacement; can locate at all angle.

14.With 5 thermocouple ports, can real-time detect and analyze temperatures at multipoint.

15.With a solid operation display function to make the temperature control more reliable.

16.It can generate SMT standard temperature removing curve automatically in different regions and different environment temperature,don’t need to set curves manually, anybody can use it even without experience, realize machine intelligence

17.With the camera that can observe the melting point of solder side, it is convenient to determine the curve (this feature is optional items). Full auto BGA repair machine

What's the Technology Parameter of full automatic BGA rework station ?

|

Max PCB Size |

W650*D610mm |

|

PCB Thickness |

0.5-8mm |

|

BGA Size |

1*1-80*80mm |

|

Min.ball pitch |

0.15mm |

|

Max Weight of BGA |

1000g |

|

Placement precision |

±0.01mm |

|

PCB Locating Way |

Outer or location hole |

|

Temperature Control |

K-type thermocouple,close loop control |

|

Lower Heating Power |

Hot air 1200W |

|

Upper Heating Power |

Hot air 1200W |

|

Bottom pre-heating |

IR5000W(2000 control) |

|

Power Supply |

(Double Phase)220V,50/60Hz |

|

Machine Dimension |

L700*W1000*H950mm(without frame) |

|

Thermocouple ports |

5 pcs |

|

Machine Weight |

140kg |

Would you mind me knowing more details about your company?

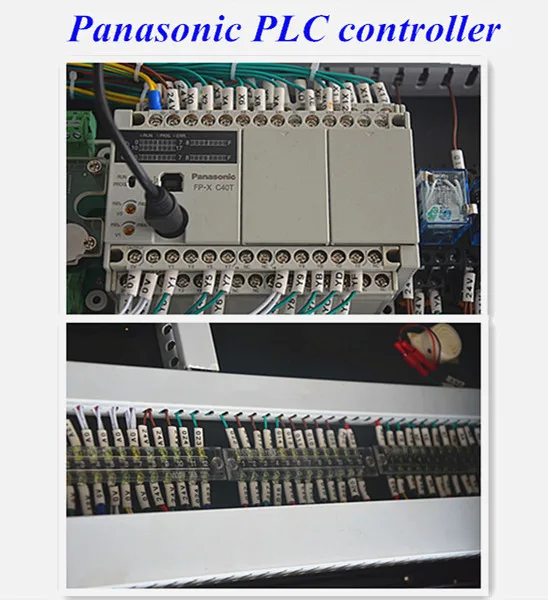

Shenzhen Wisdomshow Technology Co., Ltd, More than 10 year’s professional manufacturer of BGA rework station.Motorola,Lenovo,Nvidia,Panasonic,Haier,Samsung,Philips

are our partners,repair laptop,desktop computer,ps3,xbox,motherboard repair success rate is up to 99%.

Also,good quality BGA reballing accessories like BGA reballing station.BGA solder ball,BGA

stencils and laptop repair accessories are provided.

Our Company Information:

2015 Shanghai Nepcon Exhibition:

Worldwide Customer Visit Our Factory to Place the Order:

Approved Business Certificates:

Strong Assemble Line:

Our guarantee :

1.Source the latest, hottest and best quality goods possible.

2.Offer most competitive price.

3.Speedy and high quality customer service and after-sale service possible.

4.Deliver goods to customer all over the world with speed and precision.

Package/Delivery

1,Standard Export Wooden cases

2,Delivery in 2 workdays after payment confirm;

3,Shipping by TNT, UPS ,DHL,FEDEX or by air or by sea

4,Loading port: Shenzhen or Hongkong.

Payment terms

1,T/T: 30% deposit, Balance before shipment ; 2,Western Union; 3,Paypal; 4,Aliexpress pay; 5,Other

Warranty

We supply 3 years warranty for this BGA rework station , in the first year, offer spare

parts for free, the other 2 years, only charge fees for spare parts, technical support is

always available.

Delivery Time

Within 3 working days after the full payment

Logo/Brand

Customer's designs and logos are welcome,we can silk-print your logo company.

Youtube Demo Video Available

DS-800A https://www.youtube.com/watch?v=ERBNdRra_G0

How to contact us?

If you want to know more about it,welcome to talk with me.I‘ll reply you at the frist time.Waiting for you.

Skype ID:sales10-wisdomshow

Mob/whatsApp/Viber:+86 15200505194(wechat)

QQ:3442272488

Facebook:Abby Wds

Member Information

| Shenzhen Wisdomshow Technology Co.,Ltd. | |

|---|---|

| Country/Region: | Guang Dong - China |

| Business Nature: | Manufacturer |

| Phone: | 15200505194 |

| Contact: | Vicky Liu (Sales Manager) |

| Last Online: | 12 Aug, 2019 |

Related Products of this Company

-

Original Factory Semi-Auto Alignment

US $4800

-

BGA rework station finetech WDS-620 with

US $3200

-

110V popular around the world WDS-650

US $4800

-

Wisdomshow Economic bga chip desoldering

US $3200

-

Gear Drive control ecu motherboard

US $4800

-

automatic BGA rework machine laser

US $4800

-

Higher automatic BGA rework station

US $10800