| Model: | TS12-80 |

|---|---|

| Brand: | owen-tech |

| Origin: | Made In China |

| Category: | Industrial Supplies / Machinery / Welding Machinery |

| Label: | tubesheet welder , automatic welding , boiler welding |

| Price: |

-

|

| Min. Order: | 1 pc |

Product Description

www.owen-tech.com

Brief Introduction:

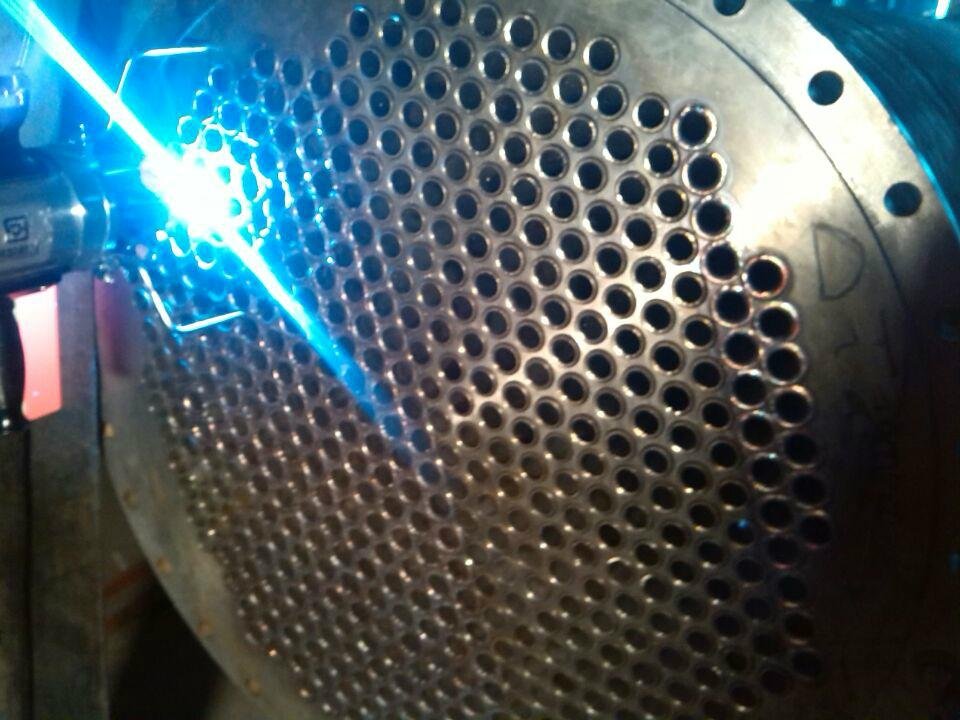

TS 12-80 Tube –Tube Sheet Pulse Argon Arc Welding Machine is specially designed for the automatic all-position welding between tube and tube sheet for the tubes with the specification of φ12~89 mm. The welding machine could be used for several tube sheet joint forms including flat head butting (flat position welding), external extension angle joint (external angle welding), indent angle joint (internal angle welding) and so forth. Moreover, the welding machine is also applicable for the welding manner with or without the requirement of filler wire. It is an important welding machine for the high pressure vessels and heat exchangers made of carbon steel, alloy steel, stainless steel and titanium alloy.

Features:

1. It is applicable for all kinds of tube-tube plate assembly method

2. The machine is of compact structure and small volume. Equipped with the elastic fixed mandrel, three-point bracket, it can be adjusted in circumferential direction, axial direction and radial direction.The movement of the machine becomes more reliable with the imported motor and fluttering mechanism.

3. Programmed control system is people-oriented. With simple operation and human-computer friendly interface, it can store a maximum of 99 welding specifications, each of which can be divided into 1-16 segments. Since it can be easily input, there is no need to require for a professional foundation.

4. The IGBT inverting-control direct-current power supply is adopted. With high-efficiency welding, and strong arc stability, the formation of the weld effect is smooth.

5. Getting rid of the limitation of on-site water source and hydraulic pressure, forced water cooling system can be used for sufficient cooling reliably and conveniently.

6. Auto AVC controlling on or off for manually adjusting

Video for welding

http://player.youku.com/player.php/sid/XODEwNDY4NzYw/v.swf

Parameters:

|

Weld tube outer diameter |

φ12mm~φ89mm |

|

Thickness |

1-6.5mm |

|

Welding torch angle of tilt |

0°~45° |

|

Welding torch speed of rotation |

0.3~6 rpm |

|

Wire feeding speed |

0.1~1.5m/min |

|

Power control mode |

IGBT inversion control |

|

Rated input voltage |

380V |

|

Power frequency and phase |

50/60 HZ, three phases, four wires |

|

Input voltage range |

380V±10% |

|

Rated input capacity |

13.9KVA |

|

Rated power input |

13.2KW |

|

Rated duty cycle |

60% |

|

Rated no-load voltage |

70V |

|

Rated welding voltage |

22.6V |

|

Welding current (background current) |

4~400A |

Member Information

| Henan owen intelligent technology Co., Ltd | |

|---|---|

| Country/Region: | He Nan - China |

| Business Nature: | Trading Company |

| Phone: | 18638501233 |

| Contact: | Owen (Manager) |

| Last Online: | 05 Feb, 2017 |