| Model: | HC51N |

|---|---|

| Brand: | HC |

| Origin: | Made In China |

| Category: | Industrial Supplies / Metallurgy Machinery |

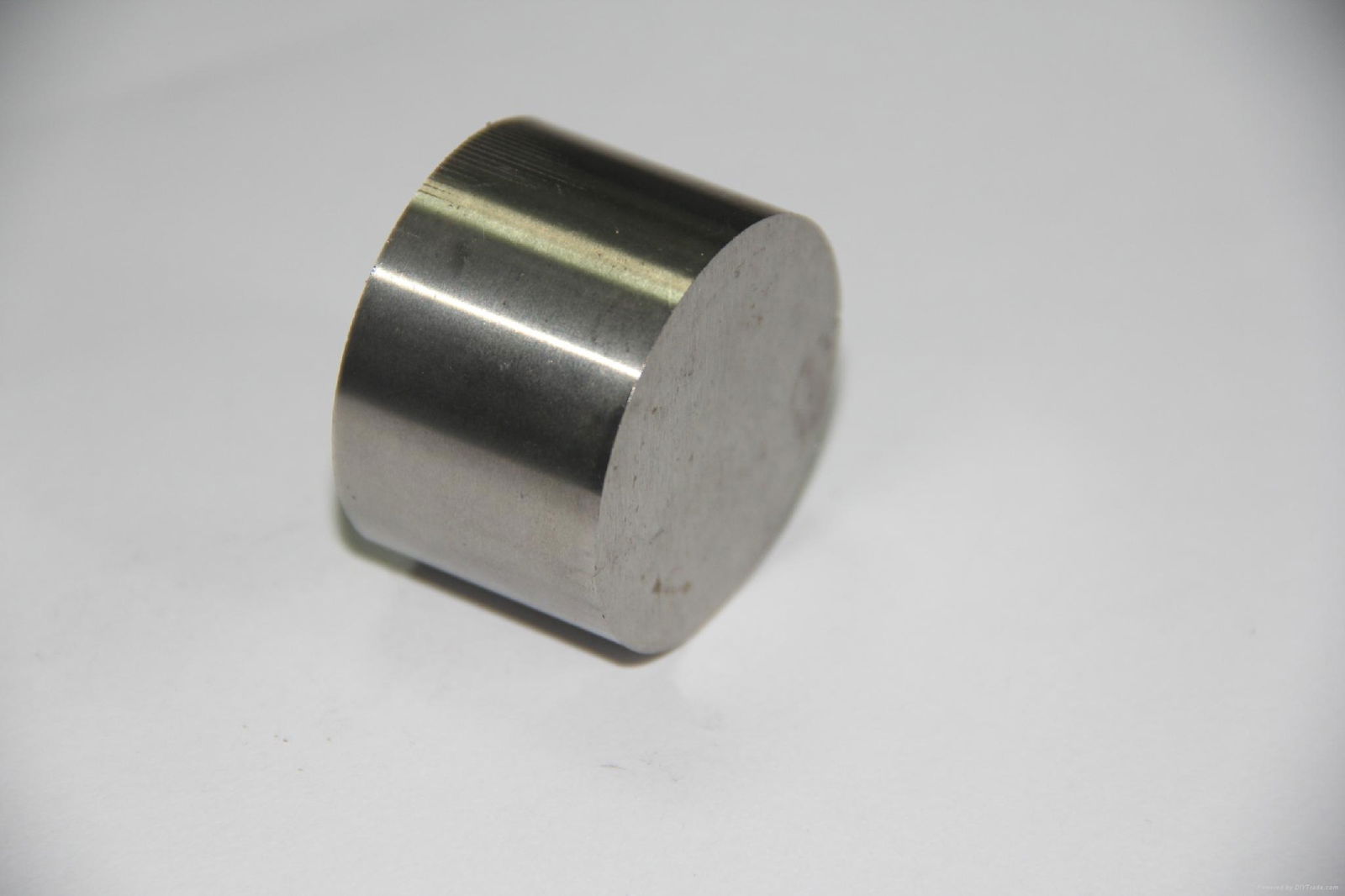

| Label: | Cylinder Magnet , Neodymium Magnet , Zinc Coating |

| Price: |

-

|

| Min. Order: | 100 pc |

Product Description

Basci infromation about products

|

Materials |

Neodymium-iron-boron (NdFeB) |

||||||||||||||

|

Dimension |

customized |

||||||||||||||

|

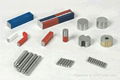

Shapes |

customized (disc, cylinder, block, ring, countersunk, segment, trapezoid, irregular) |

||||||||||||||

|

Neodymium Magnet Grade |

N35,N38,N40,N42,N45,N48,N50,N52(M,H,SH,UH,EH) |

||||||||||||||

|

Coating |

nickel/customized(Zn, Ni-Cu-Ni, Ni, gold, silver, copper, epoxy, chrome) |

||||||||||||||

|

Size tolerance |

±0.03mm for diameter/thickness, ±0.1mm for width/length |

||||||||||||||

|

Magnetization |

thickness magnetized, axially magnetized, diametrally magnetized, multi-poles magnetized, radial magnetized (customized specific requirements magnetized) |

||||||||||||||

|

Grades&Max operating temperature |

|

||||||||||||||

|

Certification |

ISO/TS16949 |

||||||||||||||

|

Applications |

Servomotors, step motors, DC motor Linear motors, brushless motor Loudspeakers, headphones, earphones Microphones, VCM, audio system Medical facilities, MRI Wind power systems, holding system Mobile accessories, magnetic separator Generatror, magnetic bearing |

||||||||||||||

|

Packing |

Carton or according to customers' request |

||||||||||||||

|

Leading Time |

15-25 days according to the order |

||||||||||||||

|

ShippingWay |

By Sea, By Air , By express |

||||||||||||||

|

Payment Item |

T/T, L/C |

Advantages:

- High consistency: deviation of the magnetic flux is ≤1% for the same batch of magnets and ≤2% for different batch of magnets

- High temperature resistance: neodymium magnets we made can be used in temperature environment reach up to 230°C, which can meet harsh temperature condition

- Good corrosion-resistance:The perfect coating of Tianhe Magnets can meet many anti-corrosion requirements. The salt spray test and humidity heat test of the high anti-corrosion coating Nickel+Copper+Epoxy is typically more than 1000 hours.

- Full-automatic electroplated production ensures magnets good coatings and especially suitable for the wet and hot environment in vehicle motor

- Experienced staff member, advanced processing technique, sound and complete systems which enable our factory to produce magnets in a wide range of grade, size, shape and coating

- More economical than SmCo magnet

Shenzhen H.C Magnetic Technologies Co.,Ltd become a magnetic industry leading manufacturer ,with its nearly 30 years expepience in this fleld.

- Certificated of ISO/TS16949

- One stop service from R&D to mass production

- Senior qualified supplier of Siemensand Philips.

- annual production capacity reach to 10,000 tons.

We sincerely looking forward to establishing long and mutual benefits business relation with new and old customers in the near future. Our honest policy and quality goods will be your lasting choice.

For more detail info, please feel free to visit our website or inquire us at any of your convenience.

Best regards,

Cindy

E-mail: technical@hcmagnetics.com

Shenzhen H.C Magnetic Technologies Co.,Ltd

5E Hanjing International Building, 23 Dengliang Road, Nanshan, Shenzhen, China 518054

Tel: 0086-755-21675569

Fax: 0086-755-21675752

Website: www.hcmagnetics.com

Member Information

| Shanxi H.C (Shenzhen H.C) Magnetic Technologies Co.,Ltd | |

|---|---|

| Country/Region: | Guang Dong - China |

| Business Nature: | Manufacturer |

| Phone: | 13471162473 |

| Contact: | Cindy (SALES) |

| Last Online: | 31 Oct, 2017 |