| Model: | TSE65/70 |

|---|---|

| Brand: | Shengrun |

| Origin: | Made In China |

| Category: | Industrial Supplies / Food, Beverage & Cereal Machine |

| Label: | "floating and sinkin , floating and sinking , "floating and sinkin |

| Price: |

US $22000

/ set

|

| Min. Order: | 1 set |

Product Description

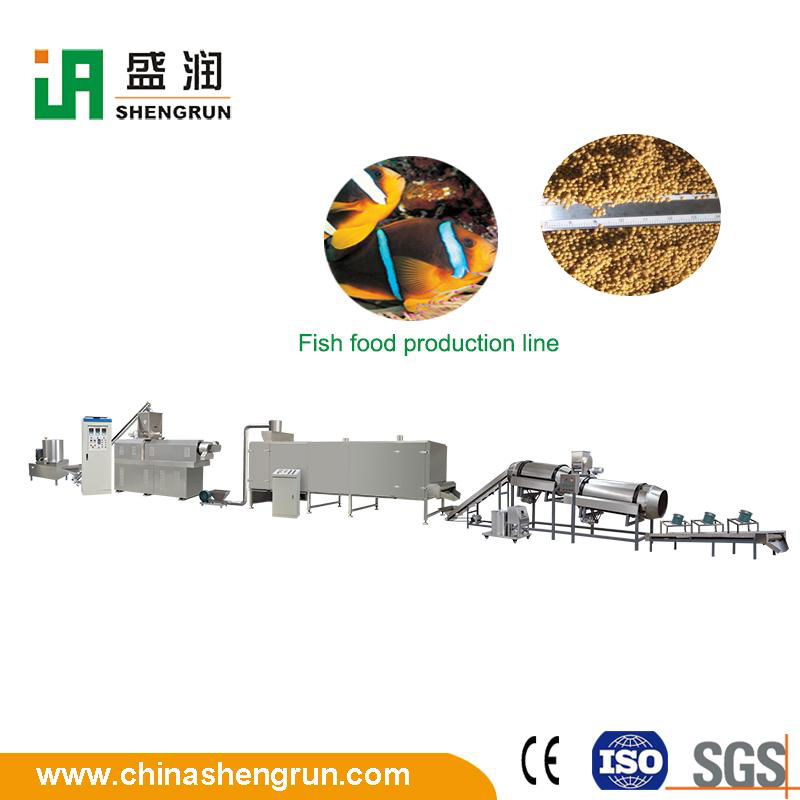

1. Introduction of production line

The fish food making machine and inflating production machine line can produce both floating and sinking feed pellets for fish, shrimp, crab, etc.

According to different fish varieties, the feed type will be various. And different ages fish require different sizes feed pellet. Our twin screw extruders can produce floating and sinking feed size range 1.2-12 mm by adjusting temperature, moisture, formulation and changing moulds.

Our fish food making machine also can be used for dry pet food production, such as dog food, cat food, bird feed, monkey food, etc.

Process flow: mixing--extruding & puffing-Conveying --Drying--flavoring--Cooling(Packing)

TSE65 fish food production line( capacity 150kg/h) flow chart

mixer → screw conveyer → TSE65 twin-screw extruder → hoister(air conveyer) → 5-layer 5 meter drying oven → single drum flavoring line → cooling machine → packing machine(optional)

TSE70/85 fish food production line( capacity 250kg/h, 500kg/h) flow chart

mixer → screw conveyer → TSE70/85 twin-screw extruder → hoister(air conveyer) → 5-layer 8 meter drying oven(7-layer 8 meter drying oven) → double-drum flavoring line → cooling machine → packing machine(optional)

TSE90/95 fish food production line( capacity 800kg/h, 1200kg/h) flow chart

raw materials mixing system → screw conveyer(bucket elevator) → Storage hopper → steam pre-conditioner → TSE90/TSE95 twin-screw extruder → hoister(air conveyer) → 7-layer 11 meter drying oven (bigger ovens) → double-drum flavoring line → cooling machine → Storage bin → packing machine(optional) As above the picture show.

2. Features of fish food production line

A. Alloy (38CrMoAL) screw made by nitriding process, high strength and wear-resting.

B. Gearbox with automatic lubrication function, extending gear life.

C. Self-cleaning ability, no need to discharge or clean the barrel and screw when roasting or replacing of materials.

D. Production line is full automatic, only need 1-2 persons to operate.

E. For the fish food capacity, we have small capacity and large capacity for your reference. You can choose the capacity according to your budget.

F. Customized voltage, we can produce the machines according to your country voltage, such as 220V, 415V, 400V etc.

3. Technical parameter

| Model | TSE65 | TSE70 | TSE85 | TSE90 | TSE95 | TSE120 |

| Installed Power | 74kw | 105kw | 110kw | 132kw | 165kw | 280kw |

| Power Consumption | 52kw | 75kw | 55kw | 75kw | 90kw | 132kw |

| Production Capacity | 100-150kg/h | 200-250kg/h | 300-500kg/h | 500-800kg/h | 800-1200kg/h | 1800-2000kg/h |

| Dimension | 17*1.3*2.2m | 20*1.5*2.2m | 32*2.0*3.5m | 35*2.5*3.8m | 40*3.5*4.5m | 45*4.5*6.0m |

4. Samples Show

The basic formula of sample

corn meal, wheat flour, wheat bran,rice flour, corn starch, de-oil soya flour, meat, bone, animal oil, vitamins, minerals, food color etc.

Humidity: the moisture is no more than 15%.

Sizes: (1) diameter: from 1.2mm-12mm. (2) length: user-defined.

5. Our machines details show

The detailed show of our extruder

The detailed show of our dryer

Member Information

| Jinan Shengrun Machinery Co., Ltd | |

|---|---|

| Country/Region: | Shan Dong - China |

| Business Nature: | Manufacturer |

| Phone: | 15688892880 |

| Contact: | Rachel Feng (Sales manager) |

| Last Online: | 23 Nov, 2016 |

Related Products of this Company

-

Competitive rice all kinds puffed food

US $25000

-

Industrial corn flakes machine

US $30000

-

Dog food maker machine line

US $20000

-

High quality pet food line machine

US $25000

-

Automatic corn puff extruder making

US $22000

-

Extruded cat food dog food extruder

US $22000

-

Full automatic dog food processing line

US $22000

-

ISO9001 certificate crispy puffed snack

US $25000

-

CE certificate tasty puffed corn food

US $25000

-

Corn snacks food extruder machine

US $20000