| Model: | NY5350 |

|---|---|

| Brand: | SEALSTAR |

| Origin: | Made In China |

| Category: | Industrial Supplies / Machine Hardware / Sealing & Gaskets |

| Label: | composite sheet , gasket sheet , sealing sheet |

| Price: |

US $9

/ kg

|

| Min. Order: | 500 kg |

Product Description

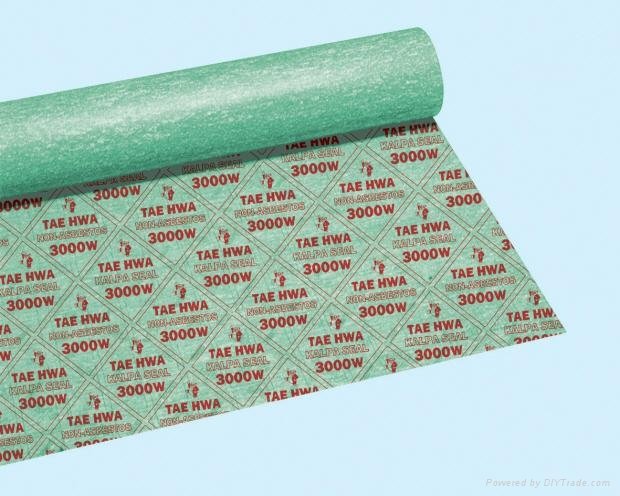

top quality non asbestos graphite sheet

NY5350 is n non-asbestos gasket sheet on the basis of graphite, mineral fibers, aramid fiber and NBR rubber (Elastic adhesives).

NY5350 is n non-asbestos gasket sheet on the basis of graphite, mineral fibers, aramid fiber and NBR rubber (Elastic adhesives).

| Item | Unit | Value | |

| Identification color/overprint | / | Black/black | |

| Density | g/cm3 | 1.50~1.70 | |

| Tensile strength ASTMF-152 | Mpa | ≥7.0 | |

| Compressibility ASTMF-36 | % | 7~17 | |

| Resilience ASTMF-36 | % | ≥45 | |

| Creep relaxation rate | N/mm² | ≤30 | |

| Leakage rateASTMF-37 | cm3/s | 1.0×10-3 | |

| Oil resistance

/Thickness growth |

ASTM1#oil (ASTMF-146) | % | ≤10 |

| ASTM3#oil (ASTMF-146) | % | ≤15 | |

| Temperature | ℃(℉) | 250~300(482~572) | |

| Applicable medium:Except for excellent oil-resistance and good strong acid resistance.it can be used Any occasion where the graphite can be used. The highest usage temperature is 350℃(662℉),long-term usage temperature should be 250℃~300℃(482℉~572℉). If roughness of the coupled surface is 1.2~3.6µm,Usage pressure should ≤5Mpa. | |||

| Note: Load with the maximum values for pressure and temperature is no possible in operation state; see p.T standard value. |

| Item | Unit | Value | |

| Identification color/overprint | / | Black/black | |

| Density | g/cm3 | 1.50~1.70 | |

| Tensile strength ASTMF-152 | Mpa | ≥7.0 | |

| Compressibility ASTMF-36 | % | 7~17 | |

| Resilience ASTMF-36 | % | ≥45 | |

| Creep relaxation rate | N/mm² | ≤30 | |

| Leakage rateASTMF-37 | cm3/s | 1.0×10-3 | |

| Oil resistance

/Thickness growth |

ASTM1#oil (ASTMF-146) | % | ≤10 |

| ASTM3#oil (ASTMF-146) | % | ≤15 | |

| Temperature | ℃(℉) | 250~300(482~572) | |

| Applicable medium:Except for excellent oil-resistance and good strong acid resistance.it can be used Any occasion where the graphite can be used. The highest usage temperature is 350℃(662℉),long-term usage temperature should be 250℃~300℃(482℉~572℉). If roughness of the coupled surface is 1.2~3.6µm,Usage pressure should ≤5Mpa. | |||

| Note: Load with the maximum values for pressure and temperature is no possible in operation state; see p.T standard value. |

| Item | Unit | Value | |

| Identification color/overprint | / | Black/black | |

| Density | g/cm3 | 1.50~1.70 | |

| Tensile strength ASTMF-152 | Mpa | ≥7.0 | |

| Compressibility ASTMF-36 | % | 7~17 | |

| Resilience ASTMF-36 | % | ≥45 | |

| Creep relaxation rate | N/mm² | ≤30 | |

| Leakage rateASTMF-37 | cm3/s | 1.0×10-3 | |

| Oil resistance

/Thickness growth |

ASTM1#oil (ASTMF-146) | % | ≤10 |

| ASTM3#oil (ASTMF-146) | % | ≤15 | |

| Temperature | ℃(℉) | 250~300(482~572) | |

| Applicable medium:Except for excellent oil-resistance and good strong acid resistance.it can be used Any occasion where the graphite can be used. The highest usage temperature is 350℃(662℉),long-term usage temperature should be 250℃~300℃(482℉~572℉). If roughness of the coupled surface is 1.2~3.6µm,Usage pressure should ≤5Mpa. | |||

| Note: Load with the maximum values for pressure and temperature is no possible in operation state; see p.T standard value. |

| Item | Unit | Value | |

| Identification color/overprint | / | Black/black | |

| Density | g/cm3 | 1.50~1.70 | |

| Tensile strength ASTMF-152 | Mpa | ≥7.0 | |

| Compressibility ASTMF-36 | % | 7~17 | |

| Resilience ASTMF-36 | % | ≥45 | |

| Creep relaxation rate | N/mm² | ≤30 | |

| Leakage rateASTMF-37 | cm3/s | 1.0×10-3 | |

| Oil resistance

/Thickness growth |

ASTM1#oil (ASTMF-146) | % | ≤10 |

| ASTM3#oil (ASTMF-146) | % | ≤15 | |

| Temperature | ℃(℉) | 250~300(482~572) | |

| Applicable medium:Except for excellent oil-resistance and good strong acid resistance.it can be used Any occasion where the graphite can be used. The highest usage temperature is 350℃(662℉),long-term usage temperature should be 250℃~300℃(482℉~572℉). If roughness of the coupled surface is 1.2~3.6µm,Usage pressure should ≤5Mpa. | |||

| Note: Load with the maximum values for pressure and temperature is no possible in operation state; see p.T standard value. |

| Item | Unit | Value | |

| Identification color/overprint | / | Black/black | |

| Density | g/cm3 | 1.50~1.70 | |

| Tensile strength ASTMF-152 | Mpa | ≥7.0 | |

| Compressibility ASTMF-36 | % | 7~17 | |

| Resilience ASTMF-36 | % | ≥45 | |

| Creep relaxation rate | N/mm² | ≤30 | |

| Leakage rateASTMF-37 | cm3/s | 1.0×10-3 | |

| Oil resistance

/Thickness growth |

ASTM1#oil (ASTMF-146) | % | ≤10 |

| ASTM3#oil (ASTMF-146) | % | ≤15 | |

| Temperature | ℃(℉) | 250~300(482~572) | |

| Applicable medium:Except for excellent oil-resistance and good strong acid resistance.it can be used Any occasion where the graphite can be used. The highest usage temperature is 350℃(662℉),long-term usage temperature should be 250℃~300℃(482℉~572℉). If roughness of the coupled surface is 1.2~3.6µm,Usage pressure should ≤5Mpa. | |||

| Note: Load with the maximum values for pressure and temperature is no possible in operation state; see p.T standard value. |

|

Item |

Value |

|

|

G/cm3 Density |

1.60±0.1 |

|

|

Mpa Intensity of tension ASTMF-152 |

≥7.0 |

|

|

% Compression rate ASTMF-36 |

7~17 |

|

|

% Springback rate ASTMF-36 |

≥45 |

|

|

Cm3/S Stopping property ASTMF-37 |

1.0x10-3 |

|

|

% Creep relaxation rate ASTMF-38B |

≤35 |

|

|

Oil resisting and incrassation rate |

ASTM1#oil(ASTMF-146) |

≤10 |

|

ASTM3#oil(ASTMF-146) |

≤15 |

|

|

℃ Usage temperature |

250~300 |

|

| Item | Unit | Value | |

| Identification color/overprint | / | Black/black | |

| Density | g/cm3 | 1.50~1.70 | |

| Tensile strength ASTMF-152 | Mpa | ≥7.0 | |

| Compressibility ASTMF-36 | % | 7~17 | |

| Resilience ASTMF-36 | % | ≥45 | |

| Creep relaxation rate | N/mm² | ≤30 | |

| Leakage rateASTMF-37 | cm3/s | 1.0×10-3 | |

| Oil resistance

/Thickness growth |

ASTM1#oil (ASTMF-146) | % | ≤10 |

| ASTM3#oil (ASTMF-146) | % | ≤15 | |

| Temperature | ℃(℉) | 250~300(482~572) | |

| Applicable medium:Except for excellent oil-resistance and good strong acid resistance.it can be used Any occasion where the graphite can be used. The highest usage temperature is 350℃(662℉),long-term usage temperature should be 250℃~300℃(482℉~572℉). If roughness of the coupled surface is 1.2~3.6µm,Usage pressure should ≤5Mpa. | |||

| Note: Load with the maximum values for pressure and temperature is no possible in operation state; see p.T standard value. |

Member Information

| Ningbo Saier Sealing Materials Co., Ltd | |

|---|---|

| Country/Region: | Zhe Jiang - China |

| Business Nature: | Manufacturer |

| Phone: | 15158359041 |

| Contact: | sharon (sales) |

| Last Online: | 22 Jun, 2012 |

Related Products of this Company

-

asbestos free rubber sheet

US $5

-

non asbestos rubber sheet

US $5.5

-

non asbestos graphite sheet

US $9.5

-

non-asbestos fiber sheet( gasket sheet)

US $6.5

-

High quality Reinforced non asbestos

US $11

-

Rubber gasket sheet

US $4.6

-

gasket sheet/material

US $5.5

-

100% Non-asbestos gasket shhet

US $3.2

-

non asbestos composite sheet

US $6.5

-

Reinforced non asbestos gasket sheet

US $8