Product Description

Flexible organ cover processing factory into parts, Tel: 0317-5691136, welcome to order.

The customized organ type protective cover makes the equipment run more smoothly, which not only ensures the protection performance of the equipment, but also increases the aesthetic performance of the equipment

technical data

Organ type protective cover can be any combination of product series, its raw materials, shape, processing method and size can be determined according to the actual situation.

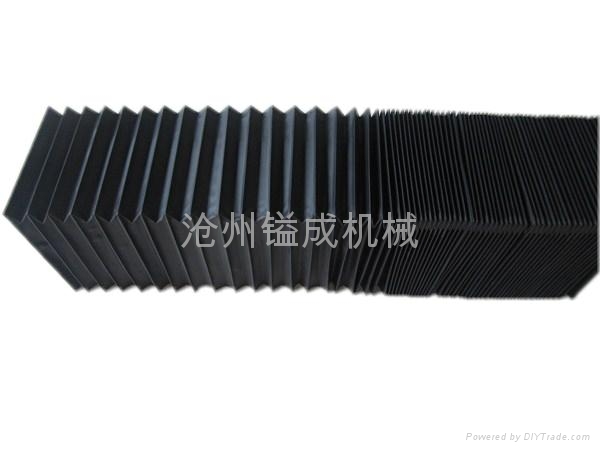

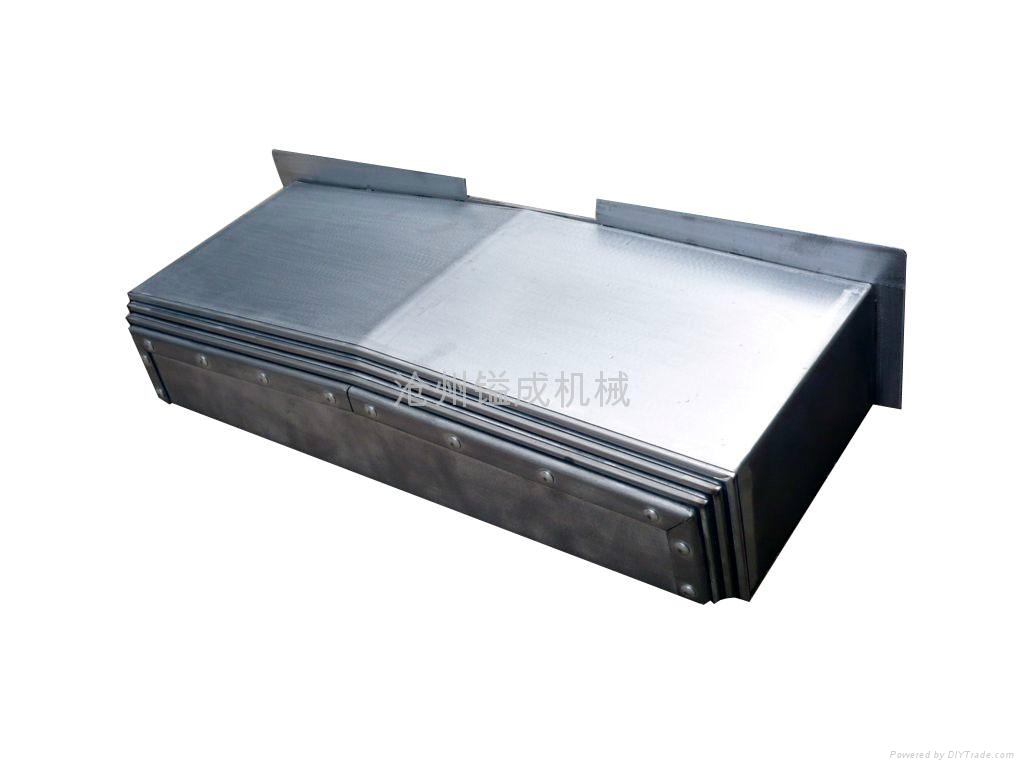

A basic component of the organ type protective cover is that each hinge is equipped with a PVC framework for supporting and stabilizing. The PVC framework can be closely connected with the external folding material through two different processing methods. In addition, organ type protective cover is more and more widely used in medicine, measurement, automatic control and food technology. These industries require dust shields and are non-toxic to food. The protective cover is more and more widely used in the lifting platform of automobile assembly line. There are several square meters of protective cover fully meet the requirements of high precision and smooth operation. The protective cover can be used horizontally, vertically or horizontally. Ensure smooth operation and no noise. By using the material with small thickness, it can be compressed to meet the requirements of the narrow working space of modern machinery. The organ type protective cover has smooth surface, regular shape and beautiful appearance, which adds color to the appearance of the machine tool and improves the grade of the machine tool. There is little difference between different styles of organ type protective cover. There are mainly two forms, one is louver shape (commonly known as "one word shape") and the other is "U" shape. The slant or roof shape improves the liquid discharge. Square is used in the field of table shape (such as lifting table, medical equipment). It can be installed afterwards and connected with adhesive tape, adhesive buckle and adhesive tape interface.

The sliding property of organ shield on the track can be improved by using special slide rolling. If the acceleration acting on the organ type protective cover is relatively large, the connecting rod device can be used to make the protective cover stretch evenly. We have solutions to almost all the technical problems of protection.

install

The fixing of organ type protective cover on mechanical equipment is very simple, and the accessories provided by the manufacturer can be used. In general, metal or plastic connection framework will be installed at both ends according to customer's requirements. A more simple method is to use Ni adhesive button, which is fast and does not need maintenance, and is convenient for loading and unloading. You can also choose to use button and other methods.

A basic component of organ protective cover is that each folding piece is equipped with a supporting PVC framework, which can be closely connected with the folding piece material through three different processing methods.

Now the most commonly used are gluing, heat sealing and sewing.

Through the use of PVC framework to increase the appearance stability of organ protective cover, this kind of stability is directly reflected in the organ protective cover to ensure that it can return to the initial state, which is its obvious advantage compared with the general protective cover made of rubber protection and solid paper.

All organ type protective covers can be used horizontally, vertically and horizontally to ensure smooth operation and no noise. Through the use of raw materials with small thickness, it can compress the requirements of narrow working space of modern machinery.

The surface of organ type protective cover is smooth, the shape is standard and the appearance is beautiful, which adds color to the appearance of machine tool and provides grade for machine tool.

There is little difference between the different styles of organ type protective cover. There are mainly two forms, one is A-shape, the other is U-shape. The inclined or house shape improves the liquid discharge. The square protective cover is used in the platform shape field (such as lifting platform, medical equipment, etc.). Can be installed afterwards, with tape, adhesive buckle, or tape lap to link.

Installation of organ protective cover

Product Image

Img 1

Img 2

Img 3

Img 4

Img 5

Send Inquiry to this Member

This member assumes full responsibility for the content of this listing. DIYTrade accepts no responsibility whatsoever in respect of such content.

To report fraudulent or illegal content, please

click here.

China Suppliers Quick Searching:

,