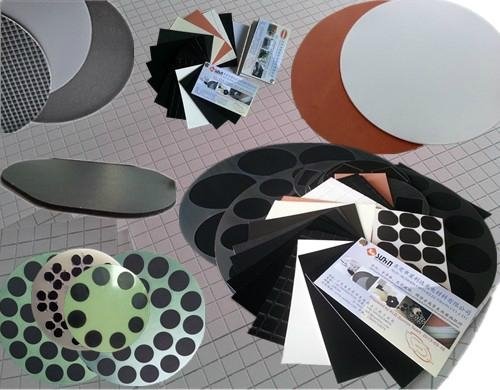

Template Isert, Polishing template , 2" & 4" FR4 carrier

Product Description

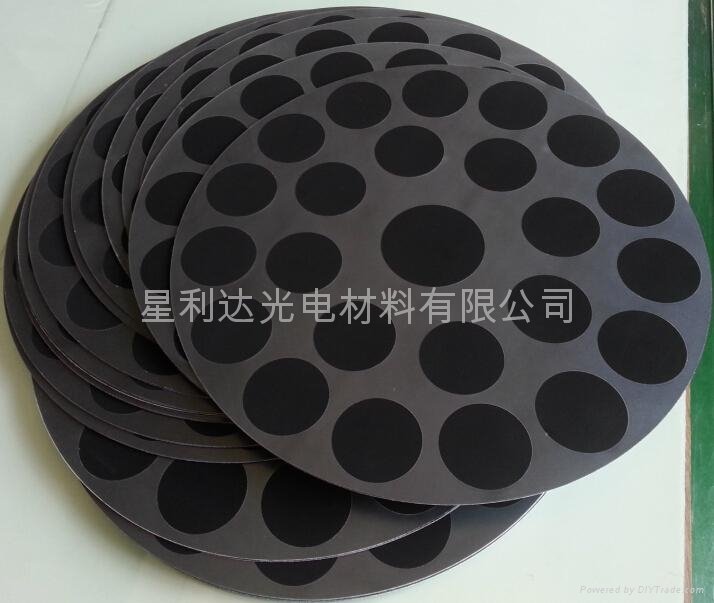

No wax polish template attached to the back pad, wax polishing pad:

Mainly used for single-sided polishing of semiconductor silicon crystal materials, sapphire, silicon epitaxial wafers and other products, electronic materials are polishing device. This is a circular multi-layer composite structure consisting of a resin material, silicon water (or slurry) within the mosaic layer is attached to the hole of the adsorption film. Using a utility model, can wafers, sapphire be no wax polish, the surface of the total thickness variation of less than 6μm, saving time and the time, effort, the utility model is simple to manufacture and low cost.

No wax polish template in the chemical mechanical polishing process used for holding the wafer; non-wax process in processing costs, production efficiency are more wax process has a greater advantage. XLD-SUNHIN the production and marketing of non-wax template can be customized according to customer selling size; XLD-SUNHIN new wax polish template template frame with high hardness, sapphire wafer polishing in competitiveness over other manufacturers of application templates.

1 according to customer requirements, samples and drawings produced!

2 The company has a strict production process standards, quality and stability!

3 drawings or only the relevant parameters can provide precision machining production!

4 free for customers design and processing or engineering drawings;

5 of equipment, available for immediate proofing, fast delivery;

Crystal / sapphire polishing precision planetary wheel support ring:

Is used in a variety of flat glass polishing process fixtures, lenses, wafers, hard disk, etc., also known as the polishing jig, polishing pads, etc.; polishing process development for many years, has been very mature, in recent years, mobile phones, tablet PCs and other mass large number of popular electronic products, the rapid development of the touch screen, lens, crystal, LED sapphire substrate polishing developing rapidly, planetary wheel from the initial raw material into a high wear blue steel glass fiber;

Planetary wheel manufacturing process is very particular about the lenses or wafers, polished stones are very sophisticated technology, so the finished product requirements for planetary wheel is also very fine, we are able to process very high precision, can be controlled within 0.02mm, section is very smooth, without any glitches, can not even see traces of processing!

Product Image

Img 1

Img 2

Img 3

Img 4

Img 5

Img 6

Img 7

Img 8

Img 9

Img 10

Img 11

Send Inquiry to this Member

Related Products of this Company

This member assumes full responsibility for the content of this listing. DIYTrade accepts no responsibility whatsoever in respect of such content.

To report fraudulent or illegal content, please

click here.

China Suppliers Quick Searching:

,