Product Description

Oil cup type pad printing machines are environmentally friendly and usually adopt a structure in which the oil cup slides forward and backward. As the printing plate lengthens, the stroke of the oil cup sliding forward and backward also increases. When the stroke exceeds 300mm, the oil cup slides forward and backward. The width of the press will increase significantly and adjustments will become cumbersome. For this reason, a pad printing machine using a left and right sliding structure of the oil cup was introduced to the market.

1) The structure of the pad printing machine is more compact

The oil cup slides in the left and right direction. While the printing area increases, the overall size of the pad printing machine does not increase. It won’t be difficult to adjust.

2) Suitable for printing long products

For some products, such as rulers, medical catheters, bicycle beams, and saw blades, the length and width of the printed patterns are disproportionate. They are often very narrow but very long. This is very convenient for printing on a pad printing machine with an oil cup cross-scraping type.

|

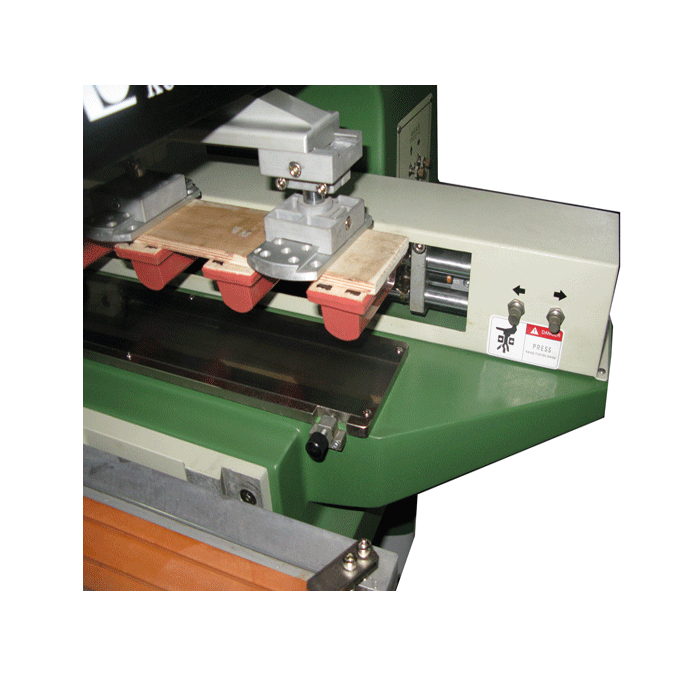

P1-420C One color pad printer with lateral movement cup //Structure

|

|

Working table

|

Standard working table with 3-size adjustment

|

|

Ink supply system

|

Closed -type system

|

|

Plate type and size

|

0.3mm Thin steel plate. Size :100*500mm.

|

|

Pad dropping control

|

Simple-cylinder , simultaneously pressing

|

|

P1-420C One color pad printer//Usage and characters

|

|

Guide

|

- Transverse movement pattern using the sealed cup, the plate can be placed even greater, larger print area;

- With sealed cup to protect environment , VOC volatilization reduced 86% and save ink over 25%.

- With coin aluminum structure ensure more stabilization and long life.

- Independent cylinder to drive sealed cup ensure removing ink completely. Make min Pressure to remove ink and prolong the life of sealed cup and steel plate;

- Both thick steel plates and thin steel plates installed , Choose according to customer requirements.

- Can print almost small size objects . So sold very nice in the world.

- Widely used in the industry field of cosmetics case, electron parts, Toys, plastics production, Housewares, gifts, decorations.

- Completely printing solution including ink and thinner , fixtures, steel plates, rubber pads provided when you send us samples;

|

|

Application fields

|

Electrons, hardware, autos, toys, gifts, Plastics, household appliances, artwork, stationery, adornment, cosmetic, commodity, sport goods, decorative lightings, woodwork, office supplies, Photo Materials, Kitchen utensils, Hotel supplies, Computer, Mobile, etc., industrial field.

|

|

P1-420C One color pad printer //Parameter

|

|

Technical parameters

|

- Max. steel plate: 100 ×500mm;

- Ink cup size: Ф90mm;

- Max. printing area :50×380 mm ;

- Printable color quantity:1;

- Max. printing speed: 1000 pcs/h;

- Table size: 165*500mm

|

|

Works supply

|

- 110V-220VPower supply;

- 5-7Bar Compress air;

|

|

Package list

|

- Package size:1.270×0.570×1.470m;

- Gross weight: 176Kg;

- CBM: 1.064133

|

|

H.S.Code

|

8443198000

|

|

Certicate

|

CE

|

|

P1-420C One color pad printer //Advantage

|

|

Function

|

- Sealed cup move from right to left and fit for printing long objects;

- Using the dimensional modulating table, can be up and down, front, left, and rotation of the adjustment, which will help precise printing;

- T-slot structure, easy installation of fixtures and products;

- Hand pick and place workpiece, operating more handy;

- Microcomputer program control, the movement is more accurate and reliable;

- Test machine can be a single action adjustment, adjustment is completed, you can use the automatic mode of operation;

- Equipped with four counters, can effectively measure the number of products;

- Structure using die-casting aluminum, lightweight and solid.

- Independent Rubber pad up and down stroke and speed adjustment function;

- Sealed cup ink system, ink savings, and also to prevent the ink in the VOC emission into the air pollution of the environment, health protection of operating personnel;

- Sealed cup glide independent driving cylinder Blade pressure and Ink Removing Completely;

- Either use the tungsten steel ring, you can use a ceramic ring, and easy to replace;

- Temporary shutdown can prevent the ink to dry within the Sealed cup with INK function;

- World famous pneumatic components to ensure the long service life of machine;

- Rubber sliding shaft with hardened guide shaft grinding of high hardness, good abrasion resistance.

|

Product Image

Img 1

Img 2

Img 3

Img 4

Img 5

Img 6

Send Inquiry to this Member

Related Products of this Company

This member assumes full responsibility for the content of this listing. DIYTrade accepts no responsibility whatsoever in respect of such content.

To report fraudulent or illegal content, please

click here.

China Suppliers Quick Searching:

,