| Model: | JY-17458 |

|---|---|

| Brand: | JY |

| Origin: | Made In China |

| Category: | Metallurgy , Mining & Energy / Metallurgy & Mining / Stainless Steel |

| Label: | DIN17458 steel pipe , DIN17458 steel tube , DIN17458 |

| Price: |

-

|

| Min. Order: | 1 ton |

| Last Online:30 Jul, 2025 |

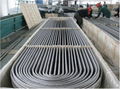

Product Introduction: Stainless Steel Pipe DIN 17458

In the realm of modern manufacturing and construction, stainless steel pipes have become a fundamental component across various industries. One of the most recognized standards for seamless circular austenitic stainless steel tubes is the DIN 17458. Known for its exceptional mechanical properties and corrosion resistance, this standard is widely used for applications requiring rigorous performance and durability.

Overview of DIN 17458

The DIN 17458 standard encompasses seamless circular austenitic stainless steel tubes that adhere to specific requirements for high-performance applications. These tubes are crucial in sectors such as chemical processing, food and beverage, pharmaceuticals, and oil and gas due to their robustness and resistance to corrosive environments.

Key Features

Seamless Design: The seamless nature of these tubes enhances their overall integrity and eliminates potential weak points, making them ideal for high-pressure applications. The absence of seams reduces the risk of leakage, ensuring long-term reliability.

Wide Size Range: DIN 17458 stainless steel pipes are available in various outer diameters (O.D.) ranging from 0.5 mm to 550 mm and wall thicknesses (W.T.) from 0.05 mm to 80 mm. This extensive range provides flexibility for engineers and designers to find the perfect fit for their specific needs.

Steel Grades: The versatility of the DIN 17458 standard is augmented by a broad selection of steel grades, including:

These grades cater to various industrial requirements, ensuring that there is a suitable option for a multitude of applications.

Applications

The applications of DIN 17458 stainless steel pipes are vast and growing. Typically, you will find these pipes in the following fields:

Advantages

Corrosion Resistance: One of the primary benefits of stainless steel is its ability to withstand corrosive environments. The chromium content in these alloys forms a passive layer of chromium oxide, protecting the surface from oxidation and rust.

Longevity and Low Maintenance: The durability of stainless steel pipes ensures that they last longer than many alternative materials, resulting in lower maintenance and replacement costs over time.

Versatility: The wide range of sizes and grades means that DIN 17458 pipes can be customized for specific applications, allowing engineers to design systems that maximize efficiency and performance.

Safety: The integrity of seamless pipes reduces the risk of failure in high-pressure settings, which is crucial in industrial applications where safety is a top priority.

Industry Insights

According to industry reports, the global market for stainless steel pipes is expected to grow significantly, driven by the expanding demand in various sectors such as construction and infrastructure development. As industries increasingly focus on sustainability and environmental impacts, the use of stainless steel — due to its recyclability and long service life — is becoming more prevalent.

Furthermore, with ongoing advancements in manufacturing processes, the quality and affordability of seamless stainless steel pipes are continually improving, making them a competitive option in comparison to traditional metal piping solutions.

Conclusion

The DIN 17458 standard represents a significant advancement in stainless steel pipe technology, offering a combination of strength, corrosion resistance, and versatility that is unmatched in many industrial applications. As industries evolve and face new challenges, the demand for reliable, high-quality materials such as those defined by this standard will undoubtedly continue to rise. Whether for chemical processing, food and beverage, pharmaceuticals, or oil and gas, selecting the right stainless steel pipe is crucial for ensuring performance and safety in demanding applications.