LX-6EL 7200bph 2L Auto Bottle Blow Molding Machine(6 Cavities)

Product Description

LX- 6EL Auto Bottle Blowing Machine Advantages

1.1 New Auto Preform Unscrambler and divided System

- Our machine adopts one-way preform-feeding structure and preform-separating is powered by servo motor structure that helps solve the preform block and abrasion problem.

- There is one photoelectric sensor to monitor the preform-loading and preform-separating process that will warn the operator to add the preforms into the hopper when lacks preform instead of stopping the machine.

- Preform are divided equidistance by servo motor. Faster and more accurate.

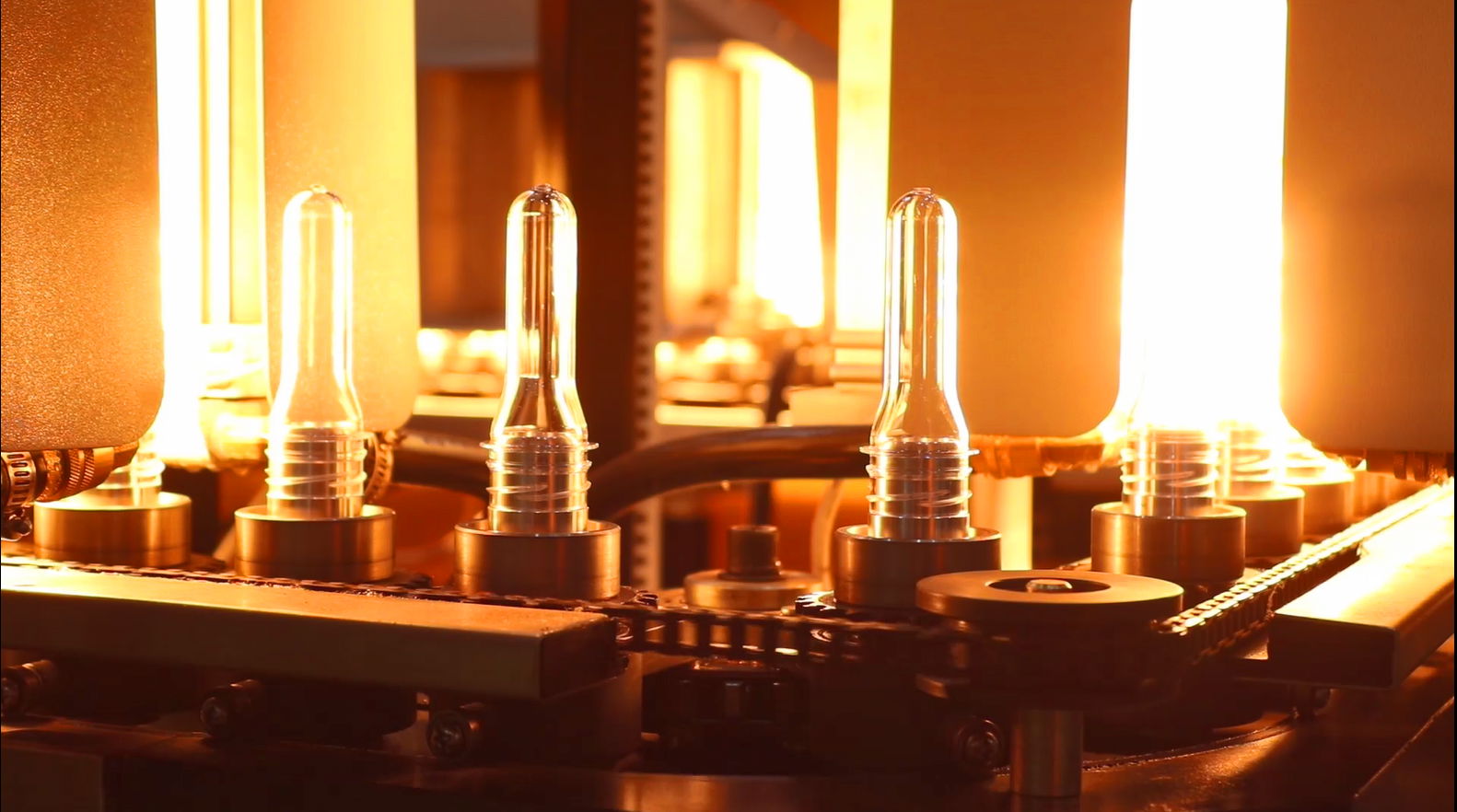

1.2 New Heating System

- Perfect heating system design helps decrease the power consumption.

- Special oven design helps power saving and easy maintain.

- Each lamp’s position and temperature can be adjusted according to clients’ needs.

- Cooling water circular system helps keep the oven temperature constant.

1.3 The Application Of Servo System On Main Transmission

- The transmission system adopts the special chains and is powered by servo motor, which helps orientate the preform heating base quickly, accurately and steadily when the machine starts running.

1.4 Servo Technology Innovation On Clamping System

- Servo technology is applied in the clamping system, which can shorten the mould-clamping time and improve productivity.

- High pressure mold-locking unit helps solve the swelling mold and big joint line problems.

1.5 Easy To Change Bottle Shape

- Drawer type mold structure design makes it easy to change the mold. Within one hour, one engineer can change a mold under the condition of same bottleneck diameter.

1.6Auto lubrication system

- Supply lubricate oil to every moving parts of the mold-clamping system in setting time and quantity

- Accurate oil inject, same inject quantity to avoiding the oil pollute the machine.

1.7 Intelligent Human-Machine Interface

- Human-machine interface control, easy operating and monitor.

- Live production information supervision and auto record production data everyday.

- Failure warning and troubleshooting.

LX-6EL machine main parameter

|

|

Item

|

LX-6EL

|

|

Main machine

|

Maximum Bottle capacity

|

2000ml

|

|

Maximum bottle diameter

|

Φ106mm

|

|

Neck diameter

|

Φ18~38mm

|

|

Maximum bottle height under neck

|

<330mm

|

|

Maximum preform height under neck

|

<155mm

|

|

Clamping stroke

|

120mm

|

|

Bottom die stroke

|

60mm

|

|

Bottle pitch

|

114.3mm

|

|

Maximum output rate (bph)

|

7,200

|

|

Number of molds

|

6

|

|

Heating part

|

Number of heating modules

|

5

|

|

Number of heating lamps

|

10

|

|

Number of preform bases

|

100

|

|

Electric part

|

Voltage

|

380V

|

|

Frequency

|

50Hz

|

|

Service power

|

30~40kw/h

|

|

Installation power

|

110kw

|

|

Air source

|

Low pressure

|

1Mpa

|

|

Low pressure air consumption

|

2m³/min

|

|

High pressure

|

3.5Mpa

|

|

High pressure air consumption

|

8m³/min

|

|

Chilled water

(Water temperature ≤18℃)

|

Pressure

|

2~4bar

|

|

Flux

|

6m³/h

|

|

Weight

|

G.W.

|

Around 10,000kg

|

|

Dimension

|

Main machine (L×W×H)

|

5800×2600×2600mm

|

|

Preform unscrambler(L×W×H)

|

4500×3500×3500mm

|

|

Remarks:

* 7200bph output rate base on 1555ml, 36 gram C’estbon water bottle.

* High pressure air consumption depends on PET bottle volume, altitude etc.

Main electric component list

|

No.

|

Name

|

Origin

|

Brand

|

|

Electric/control component

|

|

1

|

Mold-clamping servo motor

|

Japan

|

YASKAWA

|

|

2

|

Stretching servo motor

|

|

3

|

Main transmission servo motor

|

|

4

|

Preform-divided serve motor

|

|

5

|

Servo driverButton

|

|

6

|

Air switch

|

France

|

SCHNEIDER (TE)

|

|

7

|

Contactor

|

|

8

|

Intermediate relay

|

Japan

|

OMRON

|

|

9

|

PLC

|

|

10

|

PLC expand module

|

|

11

|

Touch screen

|

Taiwan

|

Panel

|

|

Valves/adaptor

|

|

1

|

Pre-blowing valve

|

USA

|

PARKER

|

|

2

|

2nd blowing valve

|

|

3

|

Exhaust valve

|

|

4

|

One-way valve

|

|

5

|

Pressurizing mold-locked motion valve

|

|

6

|

Mold-clamping lead rail

|

Taiwan

|

ABBA

|

|

Remarks: all above component are imported with original packaging. Longsun has the right to change the default parameter according to the marketing change or customer special requirement without further notification, a 5% change of the equivalent parameter will be allowable against the marketing trend and the spare parts supply condition!)

|

|

Product Image

Img 1

Img 2

Img 3

Img 4

Img 5

Img 6

Img 7

Send Inquiry to this Member

Related Products of this Company

This member assumes full responsibility for the content of this listing. DIYTrade accepts no responsibility whatsoever in respect of such content.

To report fraudulent or illegal content, please

click here.

China Suppliers Quick Searching:

,