| Model: | BS-FT |

|---|---|

| Brand: | BS |

| Origin: | Made In China |

| Category: | Metallurgy , Mining & Energy / Metallurgy & Mining / Piping Tubing |

| Label: | tubo di aletta , tubo de fin , tubo de aletas |

| Price: |

-

|

| Min. Order: | 5 ton |

| Last Online:26 Feb, 2025 |

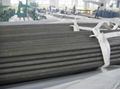

Extruded finned tubes are an innovative heat transfer solution designed to enhance thermal efficiency while protecting against environmental degradation. Composed of a bimetallic structure, these tubes feature an inner base tube, which can be made from carbon steel, stainless steel, or copper, encased in an aluminum muff tube. The fins that extend outward from the muff tube are created through a cold rolling process, enhancing not only the surface area for improved heat transfer but also providing exceptional corrosion resistance.

Key Features

Bimetallic Construction: The combination of a robust base tube with a lightweight aluminum muff tube offers the best of both worlds: strength and efficiency. The core material ensures structural integrity, while the aluminum offers significant fatigue resistance and corrosion protection.

Enhanced Heat Transfer: The unique design of extruded fins maximizes the heat exchange surface area, leading to increased thermal performance. This results in effective heat dissipation and improved system efficiency, making it an optimal choice for various industrial applications.

Corrosion Protection: One of the standout features of extruded finned tubes is their ability to protect the base tube from corrosive environments. With the base tube concealed beneath the fins, it is less exposed to atmospheric elements, ensuring prolonged service life—an essential characteristic in industries that deal with fluids and gases prone to corrosion.

Material Versatility: With an array of options for both tube and fin materials, extruded finned tubes are customizable for specific applications. The use of carbon steel, stainless steel, or copper as base materials allows for selection based on required temperature limits, pressure conditions, and chemical compatibility.

Cold Rolling Process: The cold rolling method used to form the fins does not only optimize the physical properties of the aluminum but also allows for precise control over fin geometry. This process ensures that the fins have a uniform distribution, optimizing heat transfer efficiency throughout the entire tube length.

Industry Standards and Applications

Extruded finned tubes are commonly used in various industries such as HVAC, petrochemical, power generation, and food processing. According to ASTM E2206, the performance of such tubes is evaluated under specific criteria to ensure they meet safety and efficiency standards. These standards dictate the materials' mechanical properties, thermal conductivity, resistance to corrosion, and overall durability.

Typical Specifications:

Material Standards:

Performance Expectations:

Conclusion

Extruded finned tubes represent a sophisticated solution for heat exchange applications, combining durability, efficiency, and protection. With their bimetallic construction and the protective benefits provided by the extruded aluminum fins, they are engineered to thrive in demanding environments. Whether you need improved heat transfer in your HVAC system or a reliable heat exchange solution in a petrochemical plant, these tubes meet and exceed industry standards, thereby ensuring your systems operate optimally.

For any projects requiring robust thermal management and durability, extruded finned tubes should be a primary consideration. Their adaptability, efficiency, and long-term performance make them a pivotal component in modern engineering and industrial applications. Embrace the advantage of extruded finned tubes for innovative solutions that enhance both performance and longevity.