| Model: | W456A |

|---|---|

| Brand: | OLLE |

| Origin: | Made In China |

| Category: | Home Supplies / Kitchen Implements |

| Label: | ceramic knife set , kitchen knife set , cutlery knife set |

| Price: |

-

|

| Min. Order: | 1000 set |

| Last Online:27 Nov, 2014 |

Ceramic Knife Set:

1. Classical Galaxy Handle Series N

2. Chemically Inert

3. BSCI FDA LFGB etc.

4. Sample day: 3 days

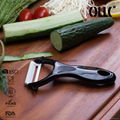

Best Cutlery Ceramic Knife Set with Acrylic Stand

Product Information

| Item No. | Weight (g) | Blade Size (mm) | Handle Length (mm) | Total Length (mm) |

| W075B/B075B | 38 | 75*20*1.6 | 112 | 178 |

| W100B/B100B | 40 | 100*21*1.6 | 112 | 202 |

| W125B/B125B | 55 | 125*25*1.8 | 130 | 243 |

| W150B/B150B | 66 | 150*35*1.8 | 132 | 270 |

Advantages of OLLE Ceramic Knife Set

1.Material: OLLE ceramic knife is the only one who uses the 4# Zirconia in China. The particles

fineness is 30% higher than the 2# Zirconia.

2.Blade: OLLE ceramic knife blades are as white as jade in perfect light transmittance, without

any stain, chromatic aberration, shadow and hidden cracks. Ceramic blades do not rust and do

not absorb either the taste or smell of the cut items. Metal ions cannot be transferred to the food.

3.Exclusive Processing Technic:OLLE is the only one in China who has the production technology

of cold isostatic pressing, and high temperature sintering by bell kiln,which is designed and produced

by OLLE. So that our products’ density is higher than 6.02 g/cm3, with 30% lower porosity.

4.Sharpness: OLLE ceramic knives’ sharpness and sharpness retention are 30% higher controlled.

The edge angle is between 11°~13°,and the cutting edge angle is bet-ween 35°~42°. OLLE ceramic

knives are extremely sharp so the nutrition of foods can be locked without sap flow or the hurt to eyes

because of volatile substance.

5.Handle: Instead of using glue and thermal bonding to make handle, we OLLE ceramic knives use

injection molding which is more sanitary, healthier and dishwasher safe.

Technical Process

OLLE ceramic knives are produced via accurate steps: 1 blade dry pressing 2 cold isostatic

pressing 3 high temperature sintering 4 accurate grinding 5 blade testing 6 handle

injection 7 sharpness testing 8 laser engraving 9 cleaning 10 packaging

OLLE has a modernized plant that expands over 30,000 square meters with an annual capacity of 20

million pieces of ceramic knives.It is the largest and most professional kitchen ceramic knife manufac

-tural in China and the first choice of OEM and ODM manufacturer.

| Annual Capacity | 20,000,000 pcs ceramic knives |

|

Quality Control |

10 inspections |

| Cost Effective |

1. Scale Effect 2. Strict Cost Control |

| Design Team | 25 Members |

| Customer Service | Within 24 hours |

| Industry Chain |

1. Ceramic knives' factory 2. Ceramic knives' mold factory 3. Ceramic knives' package factory |

| Social Responsibility | BSCI |

Chongqing OLLE Fine Ceramic Co., Ltd is a company which has strong financial strength and ch

-annels, also has the ability of R&D and resource integration in the field of household products. Our

clients includes the world's leading retail groups,such as WALMART, ALDI ,LIDL,MGB,AUCHAN etc.

Our company has long-term cooperation relationships and purchase agreements with them.

OLLE Ceramic Knife Export Business Capacity

| Market | Main Products | Revenue (USD) | Total Revenue (%) |

| Europe | Ceramic knife | 32495471.26 | 49.38 |

| Asia | Ceramic knife | 5527783.69 | 8.40 |

| North America | Ceramic knife | 10068463.15 | 15.30 |

| South America | Ceramic knife | 4080030.82 | 6.20 |

| Africa | Ceramic knife | 26322.78 | 0.04 |

| Oceania | Ceramic knife | 5317201.45 | 8.08 |

| Mid east | Ceramic knife | 4692035.44 | 7.13 |

| Central America | Ceramic knife | 3599640.09 | 5.47 |