| Model: | - |

|---|---|

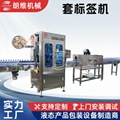

| Brand: | LONGWAY |

| Origin: | Made In China |

| Category: | Industrial Supplies / Packaging Related Machine |

| Label: | FILLING EQUIPMENT , filling machine , BOTTLED PLANT |

| Price: |

-

|

| Min. Order: | 1 pc |

| Last Online:12 Feb, 2025 |

Complete mineral water,Pure water distill water bottle manufacturing plant

mineral waterbottle manufacturing plant -Production capacity:5000-20000bph -Low maintenance rate -High efficiency,use facility

Longway's mineral water bottle manufacturing plant are specially designed to fill non-carbonated drink such as still water, flavor water, & wine in any shape 200ml to 2250ml PET bottles or glass bottle with screw caps, pressure caps or crown capping. Monobloc rinser filler capper design Water filling machine, drinking water filling machine,pure water machine.

Features: 1. The suspending bottle-neck cramping design assures whole production line more stable during the working process and it also avoids malfunctions caused by the different bottle thickness or height. The design also dramatically reduces the required quantities of interchange parts which make it more convenient to change different types of bottles on washing, filling and capping. 2. Advanced gravity filling technology from Germany and Italy is applied on the machine, which assure quick filling and high accuracy of liquid level control. 3. Magnetic torque is applied on bottle screw-capping. Constant screw capping power can be adjustable stepless and therefore will not hurt the bottles at all. 4. Horizontal swirl cap sorting device is applied to avoid damaging caps. No caps, no capping; No caps, feeding system run automatically. 5. Human-machine interface touch-screen and PLC control system are adopted on the machine. Liquid level in the tank is controlled automatically. No bottles, no filling, no capping. 6. All parts connected with water are made of food grade stainless steel. 7. All main components makers are world-known manufacturers

Specification: 1. Rinsing empty bottle, filling, and capping functions are integrated in one system, fully automatic synchronized working. Bottle travels on neck to neck from in-feed till out-feed resulting scratch free movement of bottle. 2. Pressure filling nozzles deliver fast, efficient, and accurate dispensing with minimal dripping and leakage. 3. No Bottle No Filling, no caps no capping, no caps auto stops. When bottle jam auto stop, machine accident auto stop. Open the window when machine running, machine auto paused. Heavy duty stainless steel filling pump & rinsing pump. Food grade 316L or 304stainless steel contact parts, smooth & fine Polish, no dead angles. 4. Adopted first class component from Mitsubishi, OMRON, SIEMEN, With PLC, invertors control, touch screen, sensor, switch and other electric parts 5. Machine and cable arrangement designed according to CE standard and all safety standard.

Advantages: A. High automation level, compact structure, attractive appearance, convenient and simple operation, safe and reliable and adjustable continuous production capacity, low labor intensity. B. The main machine adopts advanced PLC control technology C. The key electric elements adopt products made by international famous companies, such as Mitsubishi and Siemens. (water filling machine)

Parameter:

| Model CGF series | 16-12-6 | 18-18-6 | 24-24-8 | 32-32-10 | 40-40-10 | 50-50-12 | 60-60-15 | ||

| Washing-Filling-Capping | 16-12-6 | 18-18-6 | 24-24-8 | 32-32-10 | 40-40-10 | 50-50-12 | 60-60-15 | ||

| Producing capacity (600ml) | 2000-4000 (bph) | 5000-7000 (bph) | 8000-12000 (bph) | 12000-15000 (bph) | 16000-20000 (bph) | 20000-24000 (bph) | 25000-30000 (bph) | ||

| Applicable bottle (mm) | φ=50-108 H=170-340 330ml-2.25L | ||||||||

| Pressure (kg/cm2) | 2~3 | ||||||||

| Outside vacuum pump power (kw) | Main motor 1.5kw | Main motor 2.2kw | Main motor 3kw | Main motor 4kw | Main motor 7.5kw | Main motor 9.5kw | Main motor 12kw | ||

| Overall dimension (mm)

(LxWxH) |

2100x1400 x2500 | 2460x1720 x2650 | 3100x2100 x2650 | 3500x2500 x2650 | 4600x1800 x2650 | 5200x4500 x3400 | 6500x4500 x3400 | ||

| Weight(kg) | 2500 | 3500 | 4200 | 5500 | 6800 | 7600 | 9800 | ||