| Model: | DSE65/70/85/90 |

|---|---|

| Brand: | DINGRUN |

| Origin: | Made In China |

| Category: | Industrial Supplies / Animal Husbandry Equipment |

| Label: | pet food machine , dog feed extruder , cat Food equipment |

| Price: |

US $10000

/ pc

|

| Min. Order: | 1 pc |

| Last Online:11 Aug, 2018 |

pet food machine dog food making machine

Pet machine is suitable to make dry and wet type pet food pellet (dog food, cat food, fish food etc.)

1). All pet food equipments are made of stainless steel.

2). The pet food whole line fully continuous and automatic.

3). Dingrun provide basic pet food formula according to your require.

4). The final pet food shapes and sizes can be various by changing the mould.

5). Supply different size mould free of charge.

6). Packing machine could be supplied to work with the pet feed production line (depending on your require)

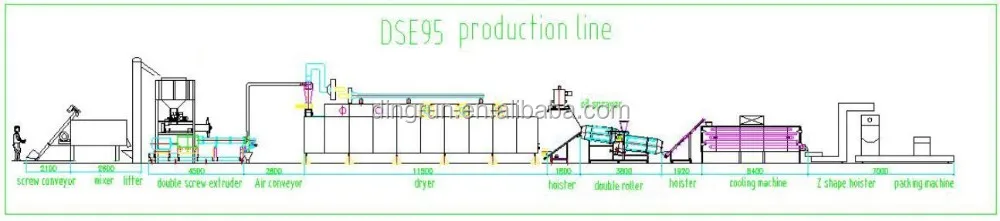

Flow chart:

grinding→mixing→extruding→drying→flavoring→cooling→packaging

Flow chart diagram:

Our engineer could design the layout drawing according to your dimension of the factory for the dog food machines.

Raw material:

Rice flour, corn flour, wheat flour, low temperature soya flakes meal, rice bran , wheat bran, fish powder, bone powder etc.

can also add fresh bone, meat, etc.

Final product:

pet food pellet

round, bone, flower, triangle shape etc.

taste customized

color customized

Equipment list in the pet food production line:

mixer→screw conveyor→twin screw extruder→air conveyor→dryer→hoister→flavoring drum and oil sprayer→cooling

machine→packing machine

|

Name |

Mixer |

|

Usage |

To mix the raw materials evenly, fast speed, no leakage. |

|

Type |

Vertical and horizontal type |

|

Motor |

3kw, 4kw, 7.5kw etc. |

|

Capacity |

20kg/time, 50kg/time, 100kg/time, 200kg/time, 500kg/time etc. |

|

Material |

stainless steel, carbon steel |

|

Name |

Twin screw extruder |

|

Usage |

To extrude the raw materials and make them to the required shape and size of the pet food pellets by mould |

|

Model |

DSE65, 70, 75, 90, 95, 120, 135 |

|

Motor |

22kw, 30kw, 55kw, 75kw, 90kw, 110kw etc. |

|

Capacity |

100kg/h to 10 ton/h |

|

Material |

Screw materials 38CrMoAl

stainless steel, carbon steel |

Dry type twin screw extruder for pet food

capacity from 100kg/h to 1 ton/h

Wet type twin screw extruder for pet food

capacity from 200kg/h to 10 ton/h

Technical parameter for pet food extruder:

|

Model |

Installed Power

(kw) |

Power Consumption (kw) |

Capacity

(kg/h) |

Dimension

(m) |

|

DSE65 |

74 |

52 |

120-180 |

17*1.2*2.2 |

|

DSE70 |

95 |

70 |

200-300 |

20*1.5*2.2 |

|

DSE75 |

110 |

82 |

250-400 |

26*1.5*2.2 |

|

DSE85 |

139 |

104 |

400-800 |

28*3.5*4.3 |

|

DSE90 |

132 |

75 |

800-1200 |

28*3.5*4.3 |

|

DSE95 |

165 |

90 |

1500-2000 |

35*3.5*4.3 |

|

DSE120 |

469 |

380 |

2000-2500 |

45*20*22 |

|

DSE135 |

712 |

570 |

3000-3500 |

50*20*25 |

|

Name |

Dryer (oven) |

|

Usage |

the expanded food go through the “s” passage, to be dried to increase the self life. |

|

Type |

electrical, steam, gas fired, diesel fired heating type |

|

Model |

KX-3-5, KX-5-5, KX-5-8, KX-5-10, KX-7-10 etc. |

|

Capacity |

100kg/h to 10 ton/h |

|

Material |

stainless steel, carbon steel |

Electrical heating dryer

Gas or Diesel fired heating dryer

|

Name |

Flavoring machine |

|

Usage |

To mix the oil and flavors on the surface of the pet food |

|

Type |

single and double flavoring drum |

|

Motor |

0.75kw |

|

Capacity |

100kg/h to 10 ton/h |

|

Material |

stainless steel |

|

Name |

Packaging machine |

|

Usage |

To pack the pet food with required weight |

|

Type |

Automatic |

|

Flowing Process |

Manual Bag placing→Automatic filling→Automatic weighing→ Automatic bag conveyor→Automatic bag sewing or heat sealing |

|

Weight range |

1-5kg/bag, 5-25kg/bag, 25-50kg/bag |

|

Material |

stainless steel, carbon steel |

Packing & Delivery

1. Inside package is plastic film, outside is wooden or plywood case, or fumigation package with

certificate, (based on the customers' need).

2. Ship, train, express or upon clients' demands.

Our Service

1)Free management of equipments' long distance shipping;

2)Provide factory layout according to your factory size in advance;

3)Provide the basic formula;

4)Inspect the machine before leaving the factory;

5)Oversea installation and commissioning the equipment;

6)Technician will work with your workers together and teach your workers how to install machines,

how to operate machines, how to maintain machines during daily working;

7)Our engineers will teach your workers how to clean the extruder, how to change the screw,

how to change barrel etc, and provide technology support with you forever;

8)Provide English Version of Installation/Operation/Service/Maintenance Manual.

Our Company

Jinan Dingrun Machinery Co., Ltd. is a leading manufacturer of high quality twin screw extruder and single screw extruders for food industries. We have almost ten years’experience of working with our customers providing special designs and practical solutions for a wide range of process needs. Free formula, local installation, workshop design, machine inspection service are provided.

FAQ

1. Q: Are you a trading company or a manufacturer?

A: We are the manufacturer, which has almost 10 years of experience in this industry.

2. Q: How can I get to your company?

A: That's great you can visit our factory, welcome! You can get a flight to Jinan Airport. Our factories are just about 30 minutes drive away from Jinan Airport.We are so glad to arrange our car pick you up!

3. Q: How long is your guarantee?

A: One year(Calculated from the equipment arrives at the customer's side.).

After this period we will definitely support you when needed.

You will be welcome to contact us with any problem may happened.

4. Q: Will you send engineers to install the plant?

A: yes, our engineer will go to your place to install the equipments, and for training.

| Price Terms: | FOB QINGDAO |

|---|---|

| Payment Terms: | T/T, L/C. D/A, D/P |

| Packing: | Wooden case |

| Lead Time: | Within 30 days after receiving payment |

| Standards Certificate: | SGS CE ISO |

| Product condition: | New |

| Automacic: | Full automatic |

| Raw materials: | wheat flour,corn/rice powder,meat, fish meal |

| Capacity: | 100-3000kg/h |

| Dimension: | various |

| Installed power: | 120kw |