| Model: | JF |

|---|---|

| Brand: | jufeng |

| Origin: | Made In China |

| Category: | Industrial Supplies / Machinery / Separation Equipment |

| Label: | aluminum plastic , recycling plant , recycling |

| Price: |

¥100000

/ set

|

| Min. Order: | 1 set |

| Last Online:20 Sep, 2016 |

Aluminum-plastic panel recycling equipment

Introduction:

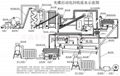

Aluminum-plastic plate recycling (separation of aluminum-plastic plate, aluminum-plastic pipe ) : Not only is the technology used for various polyethylene aluminum-plastic plate ,poly chlorine aluminum-plastic plate,aluminum-plastic pipe,aluminum-plastic bottle cap,automobile decorations,but it is used for cooper-plastic materials such as various of wires and cables and so on . The materials is sent to the large crusher directly by hook machine,then pass though secondary crushing,tertiary grinding powder decomposition and vibrating screen.The material decomposed are separated into plastic and metal in one time by the six -roller electric separator.It is a technology with low cost and high efficiency and recovery rate can reach 99.8%. It adopts physical method ,namely ,dry method separation ,which doesn’t involve the heating, fire,water and other chemical raw materials,therefore no pollution will be produced. Our company has four patents in the process, patent number: 200810141172.5, 200810141174.4, 200820148814 and 200910249968.7 x.

Production line features:

1,The machine can separate directly for the following materials :for the whole piece of aluminum-plastic sheet, width is less than 180 cm,thickness is less than 14 mm, for the various of lumps ,diameter less is than180 cm.

2,All production lines are mechanical automation operation, only need to 1-2 people, reducing the consumption of human resources.

3,There are many feeding bins in the production line, if one part of them breakdown, it does not affect other parts run normally.

4,This production line is used widely for different conductivity compounds of metal and nonmetal, they are all separated with exchanging screen meshes and adjusting all parts of equipment.

5,Production line installation is convenient with a variety of assembly method, can adapt to different venues.