| Model: | - |

|---|---|

| Brand: | - |

| Origin: | Made In Ukraine |

| Category: | Industrial Supplies / Construction Machine |

| Label: | modified bitumen , bitumen modification , Kraton |

| Price: |

-

|

| Min. Order: | 1 pc |

UMBP-22P bitumen modification unit is designed for production of modified bitumen, including polymer bitumen binding for preparation of top coat asphalt concrete, surface treatment of roads, protective layers for concrete, membrane type crack sealants, bitumen-elastomeric sealant mastics and roofing by mixing bitumen with polymers.

The unit may be operated either outdoors under canopy or indoors with forced ventilation. The unit may be operated in ambient temperatures from +5°Сto +40°С.

Specifications Parameter Value

1. Capacity, ton/hour, minimum 20*

2. Amount of polymer per 1m³ bitumen, kg 10…60

3. Amount of plasticizer per 1 m³ 10…100

4. Amount of adhesive additive per 1 m³ bitumen, liters (max) 10

5. Mode of operation Continuous

6. Nominalpower, kW

-mill 2х55=110

-bitumen pumps 2х18=36

-plasticizer supply pump 1.1

-adhesive additive supply pump 0.25

-screw conveyor drive 3

-weight conveyor and screw conveyor drives 0,43

-screw mixer drive 5.5

-total 157

7. Power

- voltage, V 380

- frequency, Hz 50

8. Dimensions (without assemblies removed for transportation), mm max

- length 6050

- height 2570

- width 3360

8. Max weight, kg 5860

*The performance specification were obtained when operating with power polymers Kraton-D, Kraton D-1107 and Kraton D-1192.

Performance specifications may vary if the unit is operated with the same polymers in pellets or other polymer products. Contact the manufacturer when selecting other polymers

Unit design

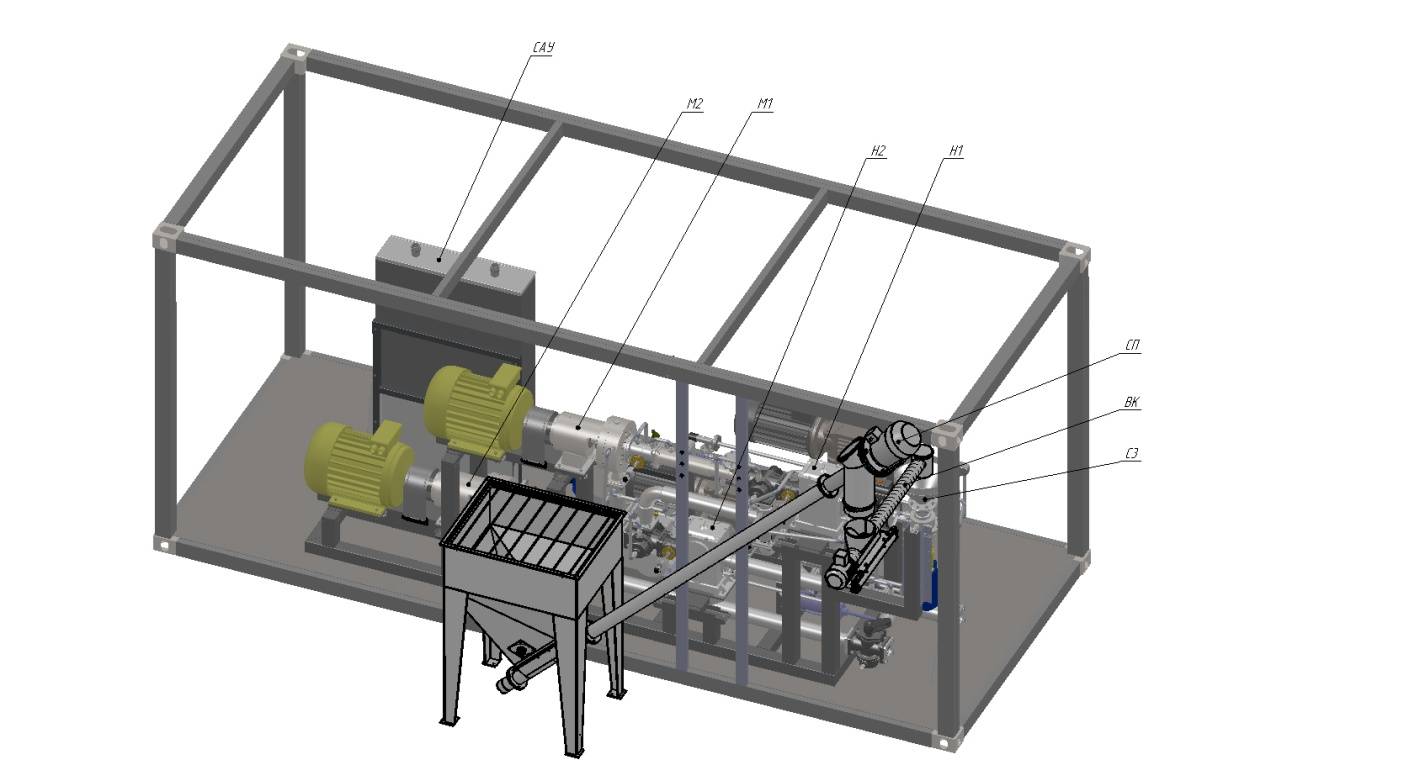

The following assemblies are mounted on the unit’s frame:

Two high pressure bitumen pumps H1, H2, two hydrodynamic mixers C1, C2; (C1 – bitumen/polymer mixer, C2 – bitumen mixer with bitumen and polymer mix), two disperser mills M1, M2, polymer input hopper from screw conveyor V, weight conveyor BK, heated bitumen pipelines with regulation and stop valves, plasticizer input assembly (pump H3), adhesion additive input assembly (portioning pump ND).The unit ships with a spiral conveyor for adjustment of polymer quantity and supply rate.

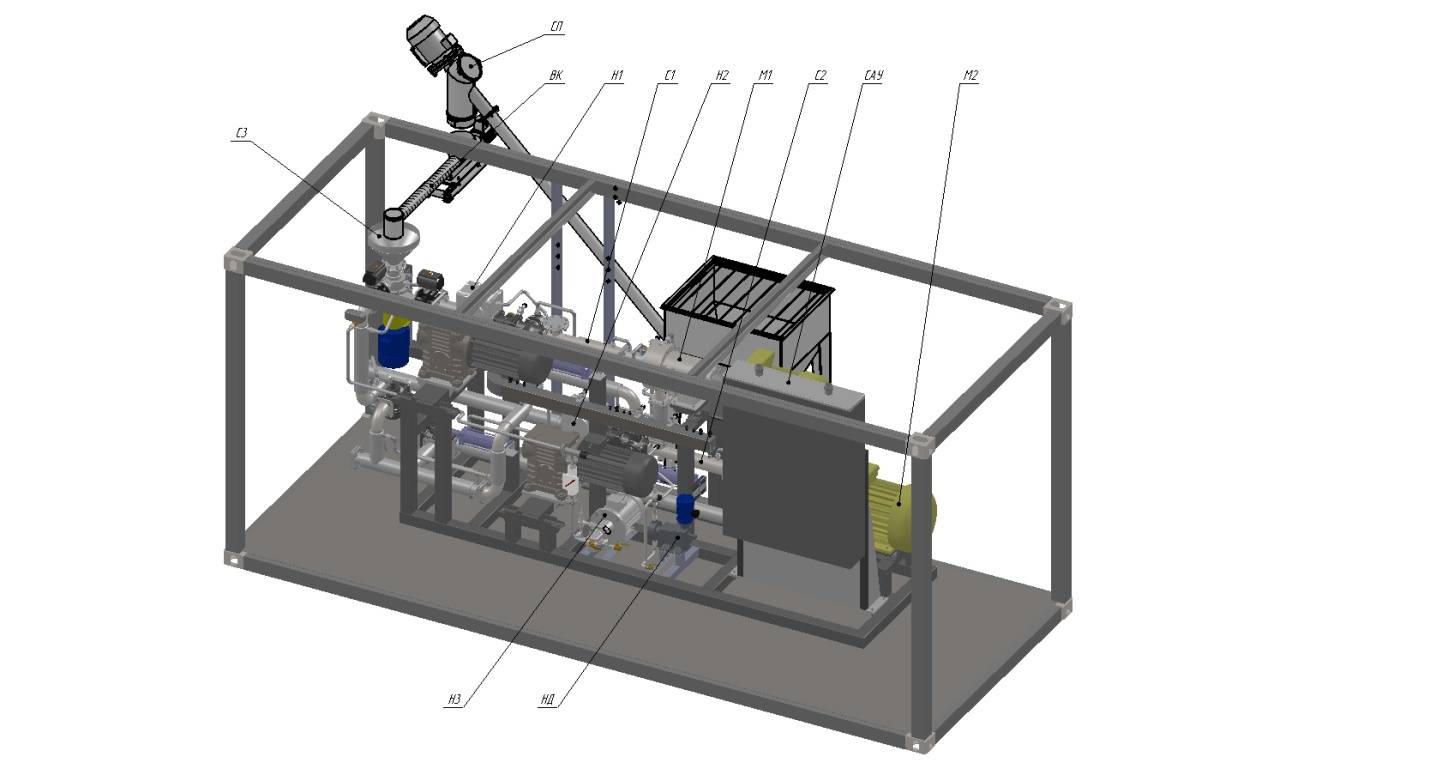

Unit general diagram

Н1,Н2 – bitumen to mixer pumps; Н3 – plasticizer pump; ND – adhesion additive portioning pump; М1, М2 – mills; М3 – polymer screw conveyor drive; М4 – weight conveyor drive; М5 – spiral conveyor drive; С3 – screw conveyor; ВК– weight conveyor; С1, С2 – hydrodynamic mixers; РМ– plasticizer flow meter; КТ1 – pressure and temperature control before mixer С1; КТ2 – pressure and temperature control before mixer С2; КТ3 – pressure control before mill М1; КТ4 – pressure control before mill М2; К1, К2, К3 – three way pneumatic bitumen valves; КР1– manual bitumen valve; К4 , К7– pneumatic ball valve; К5, К6 – manual ball valves; К8, К9 –pneumatic ball valves; СП – spiral conveyor.

The bitumen is supplied to the unit’s pumps H1 and H2 by pipelines. Depending on the position of the three way valves K1, K2 the pump supplies bitumen either back into the bitumen storage tank, or to the mixer C1 and C2. Bitumen is mixed with polymer before pump H1 by screw mixer C3.

Polymer is supplied to hopper B by spiral conveyor СПthrough weight conveyor BK. Depending on the set concentration of the polymer in bitumen, the conveyors tension sensors control the speed of the spiral conveyor and ensure correct supply of polymer.

The evenly distributed and portioned polymer in bitumen in the form of bitumen polymer mix is first homogenized in the hydrodynamic mixer C1 and then goes to the mill M1 for further grinding.

From the mill M1 the bitumen polymer mix is supplied to the vacuum chamber of the mixer C2, where it is mixed with pure bitumen and homogenized. For final dispersion the product after mixer C2 goes to the mill M2, from there it passes through three way valve K3 to the bitumen output line.

The plasticizer supply assembly is based on the pump H3, regulation valve K3 and flow meter PM. The plasticizer is measured into the vacuum chamber of the mixer C1. Plasticizer consumption is set by the regulation valve KP and is monitored by flow meter PM.

The adhesion additive is supplied by the portioning pump H4 into the vacuum chamber of the hydrodynamic mixer C2.