| Model: | drilling rig |

|---|---|

| Brand: | unimate |

| Origin: | Made In China |

| Category: | Industrial Supplies / Construction Machine |

| Label: | drilling rig , anchor rig , hydraulic drig |

| Price: |

-

|

| Min. Order: | 1 pc |

| Last Online:18 Dec, 2014 |

high quality factory direct micro drilling rig

http://chinaunimate.en.alibaba.com/productgrouplist-217014526/Hydraulic_Microdrilling_Rig.html

Microdrilling Rig

UMR-8 is a newly developed multifunctional drill rig for versatile engineering applications e.g. anchoring, micro piling, jet grouting etc. having a complete range of adaptability in the field of foundation construction, tunnel construction, geological survey and slope protection construction.

1. Advanced Technical Performance

Unimate has many years of professional experience in the R&D of foundation construction equipment, the rig gained a number of patents and the overall quality has reached the international advanced level.

2. Reliable Quality

All key components adopt world famous brands, like Cummins engine, Sam hydraulic pump, cost-effective Hyde main valve, Eaton rotary head.

3. Reasonable Construction Design

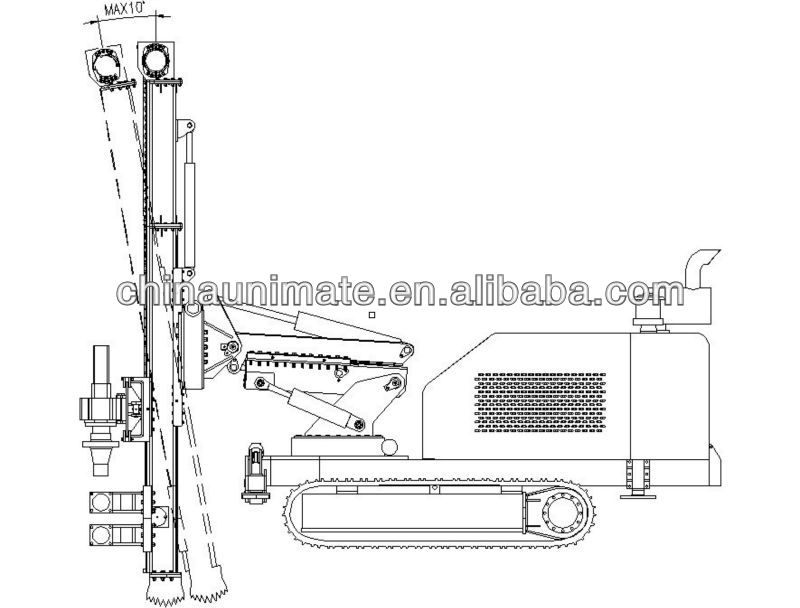

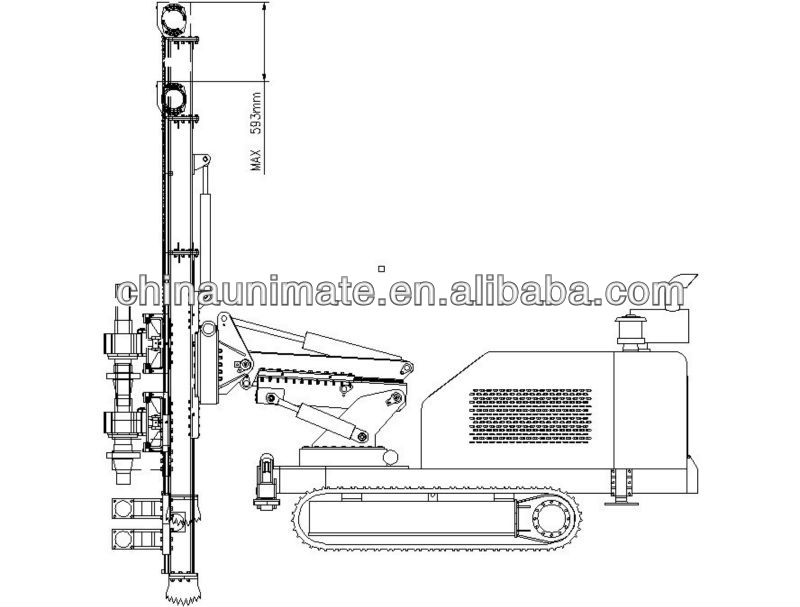

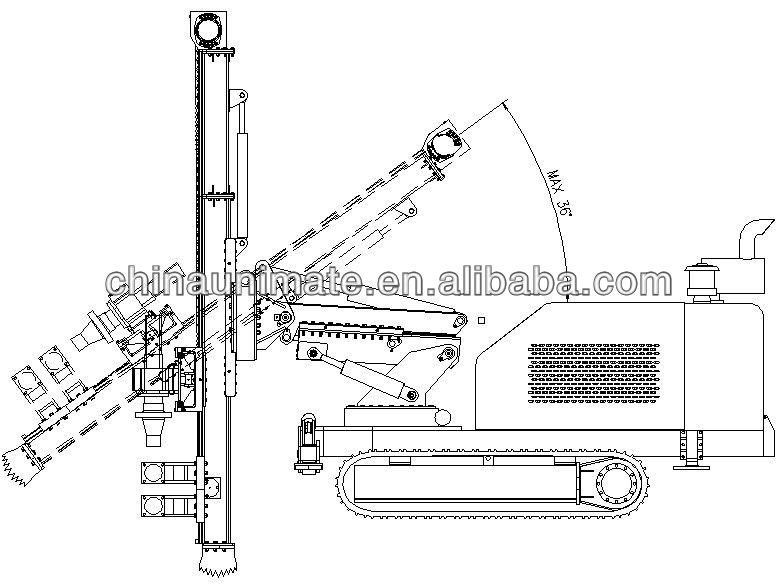

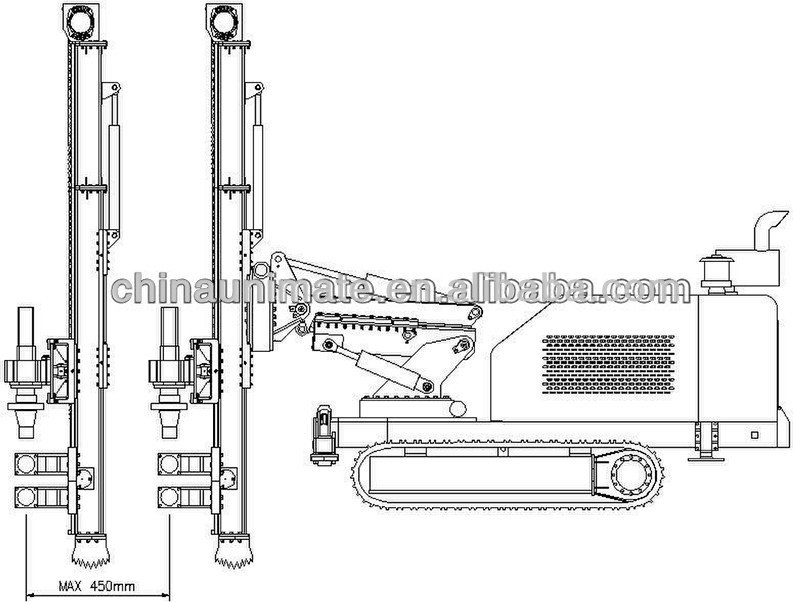

Dual slewing ring system, telescopic boom and sliding mast enables the machine to realize flexiblemovement and multi-angle changes, applicable to a variety of working conditions.

4. Comfortable Operation System

High level operation interface and convenient operation handle. Wired and remote radio control system are both available on request..

5. Convenient Maintenance

Reasonable design, integrated configuration and regular hydraulic pipe makemaintenance easy and convenient.

Microdrilling Rig FEATURES

Undercarriage

1. World famous brand Commins diesel enginewith aftersale service offices around the world makes maintenancemore convenient.

Engine

Sound-proofed power pack.

Diesel engine Cummins 4BTAA3.9-C125

Rated Power: 93 kW @ 2300 rpm.

Gasoline tank capacity: 75 l.

2. Uniqueoutrigger structure, reasonable gravity distribution and lower ground pressure make UMR-6 work with great stability.

3. Integrated electronic control system combines the engine and hydraulic pump control, the rig logical control and fault diagnosis system, which makes the engine automatically adjusts the speed to power and optimizeoperation mode.Even under extreme conditions, it alsocan output maximum torque stably to prevent engine flameout.

|

Track shoes width |

mm | 300 |

| Overall length | mm | 2200 |

| Overall width | mm | 1600 |

| Traction force | KN | 40 |

| Travelling speed | km/h | 1.5 |

| Avarage ground pressure | MPa | 0.05 |

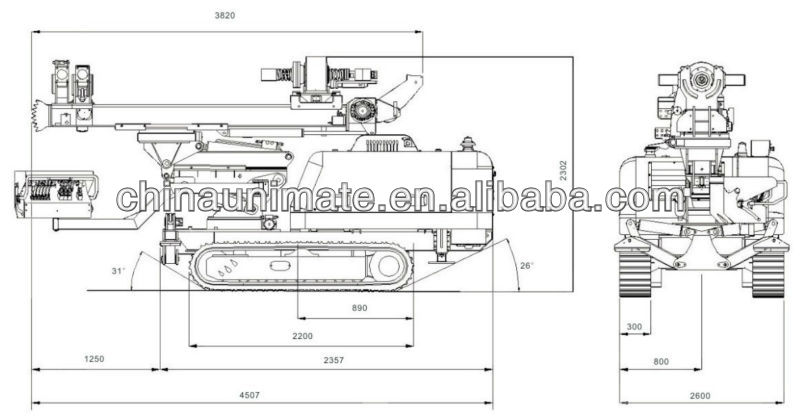

Working devices

1. The first slewing ring fitted on base machine enables drilling parallel to the tracks up to +/- 90°.

The second kinematic allows to achieve an overall mast rotation equal to +/- 180°.In order to increase the versatility of the drilling unit, UMR-6 is equipped with telescopic boomand sliding mast withvariable stroke.

UMR-6 can set the drilling directs in full range which are able to meet the construction requests in both open air and tunnel.

2. With Hydraulic clamp & breaker which can reduce the labor and enhance the labor efficiency.

Rotary head of large torque with two grades is equipped on UMR-6, which can realize various drilling processes.

3. Optional drilling tools:

Drilling rod

Casing tube

Drilling bit

Once drilling in the unstable formation, UMR-6 can drill the hole with the help of casing tube in high drilling efficiency and high quantity.

Movements

Hydraulic system

1. Main pump is with control in constant power. Main oil circuit system is with load sensing, hydraulic pilot and proportional control. The Hydraulic system features by the quick response and low energy consumption.

2. The cylinder with balance valve enables the working device and mast to move in a steady speed and avoid hydraulic shock in operation.

Hydraulic system

Main pump (variable axial piston type with load sensing) delivery: 145 l/min. (max. set pressure 260 Mpa).

Service pumps delivery: 78 + 37 + 32 l/min.

Oil tank capacity: 230 l.

Control system

1. Intelligent fault detectionsystem which displays the states of each executive parts and logic interlock system can avoid the misoperation risk.

2. Handles for hydraulic control setting in different regions are flexible and convenient, which can also avoid the misoperation risk of the driver.

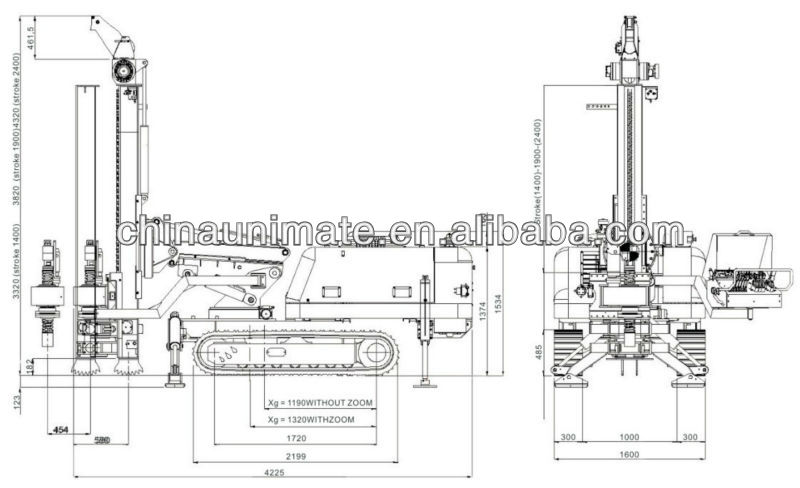

Demensions

|

Transport width |

mm |

1600 |

|

Transport height |

mm |

2300 |

|

Transport length |

mm |

4700 |

|

Total weight (approx.) |

kg |

6000 |

|

Max drilling depth |

M |

80 |

|

Clamping diameter range |

mm |

50-254 |

Microdrilling Rig Images:

Enterprise Culture:

| Mission | Improving the levl of foundation construction technology |

| Vision | To be the top foundation equipment manufacturer in the world |

| Spirit | To be the best or nothing |

| Service Concept | To offer our clients with a full-package foundation solutions |

Patent: