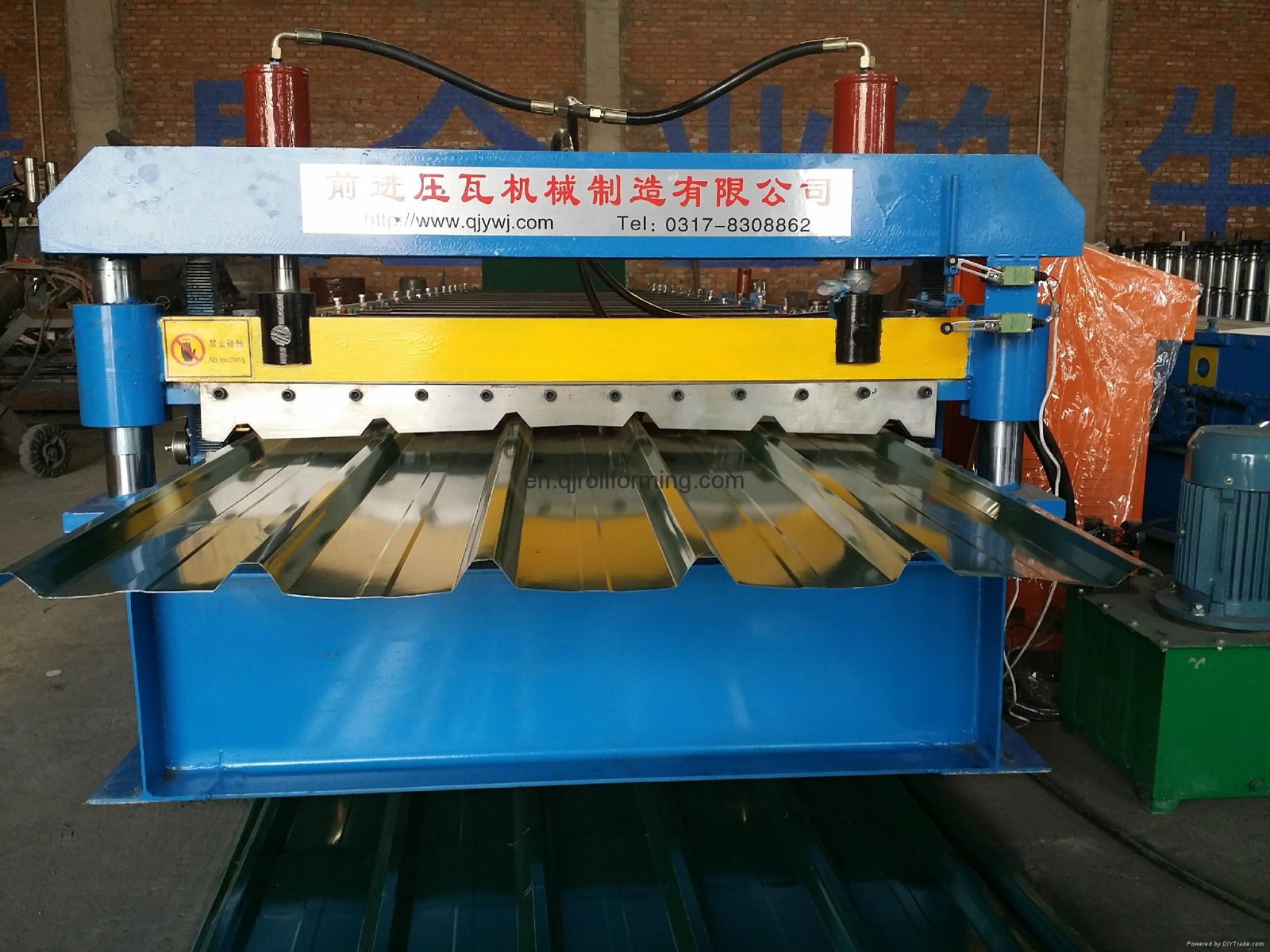

Trapezoid Roof Sheet Roll Forming Machine

Product Description

MAIN TECHNICAL COMPONENTS

1.Passive decoiler ---------1pc

2.Roll former --------------1pc

3.Cutting system------------1set

4.Hydraulic station----------1pc

5.Control system----------- 1set (“Delta” PLC,”Omron” encoder,”SAJ” frequency converter )

6.Exit rack--------------------2pcs

TECHNICAL PARAMETERS

Passive De-coiler

- inner diameter of coil: Ф500mm

- outer diameter of coil: Ф1500mm

- Passive decoiler: load bearing 5tons, tighten manually, passive loading

Roll Forming Machine:

- roll forming station: 16 stations

- machine construction: integral wall panel type

- transmission: sprocket and chain drive

- main power: 5.5KW 380V 50HZ three-phase

- rolling speed: 15-20 meters/minute

- material of rollers:45# steel, hard chrome plating

- diameter of axis: Ф70mm

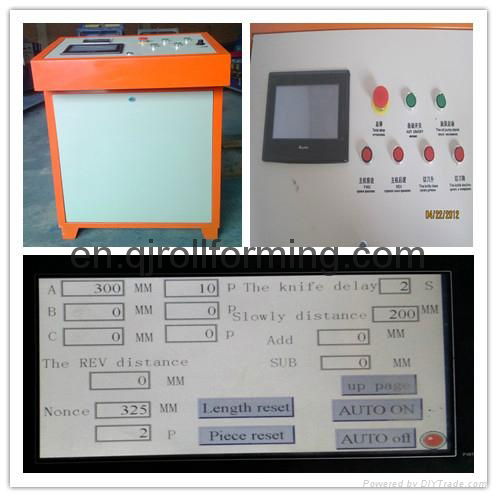

PLC Control System:

- length measurement:encoder

- control system :PLC, touch screen

- forming machine dimension: 9.2m*1,5m*1,5m

Hydraulic Cutting:

- cutter: hydraulic cutter(Note:Finished roofing production fall on the exit rack directly)

- blade material: Cr12 / heat treated HRC58-62

- power of hydraulic station:3KW 380V 50HZ three-phase

Exit Rack

- Length: 3meters

- Roller guiding system

Product Image

Img 1

Img 2

Img 3

Img 4

Img 5

Send Inquiry to this Member

Related Products of this Company

This member assumes full responsibility for the content of this listing. DIYTrade accepts no responsibility whatsoever in respect of such content.

To report fraudulent or illegal content, please

click here.

China Suppliers Quick Searching:

,