| Model: | x50crmov15 |

|---|---|

| Brand: | Changjiang |

| Origin: | Made In China |

| Category: | Metallurgy , Mining & Energy / Metallurgy & Mining / Stainless Steel |

| Label: | x50crmov1 stainless , x50crmov15 steel , knife steel |

| Price: |

US $1000

/ pc

|

| Min. Order: | 1 pc |

| Last Online:23 Apr, 2015 |

5Cr15Mov/420MoV stainless steels,1.4116 steel plate for cutting tools

Designation by Standards

EN 1.4116 / 420MoV

| Euronorm | Nom. | AISI / ASTM / UNS | GB |

| 1.4116 | X50CrMoV15 | 420MoV | 5Cr15MoV |

Chemical composition

|

|

C |

Si |

Mn |

P |

S |

Cr |

Mo |

V |

|

X50CrMoV15 |

0.45-0.55 |

≤1.00 |

≤1.00 |

≤0.040 |

≤0.015 |

14.0-15.00 |

0.50~0.80 |

0.10~0.20 |

|

5Cr15MoV |

0.51-0.55 |

≤1.00 |

≤1.00 |

≤0.035 |

≤0.030 |

14.6-15.00 |

0.50-0.80 |

0.10-0.15 |

Description

This is a high carbon martensitic stainless steel with moderate corrosion resistance good strength and the ability to obtain and keep excellent hardness (Rc 56) and wear resistance.

Applications

Ball bearings and races, gage blocks, molds and dies, cutlery, valve components, knives and measuring instruments. All kinds of cutting tools - surgical instruments, pressing dies for synthetic resin.

Soft Annealing

Heat to 730-780oC, cool slowly.

Hardening

Harden from a temperature of 980-1030oC followed by oil or air quenching.

Tempering

Tempering temperature: Please see the diagram bellow.

Forging

Hot forming temperature: 1100-800oC.

Machinability

Best machined in the annealed condition. Tough, stringy chips can be best handled by the use of chip breakers. Carbide or ceramic tooling is recommended.

Corrosion Resistance

Resistant to a wide variety of media including fresh water, steam, petroleum products and alcohol.

Welding

This steel is not commonly welded due to its tendency to air harden. If it must be welded, preheat to 260oC and post weld treat at 732-760oC for 6 hours followed by a slow furnace cooling to avoid cracking.

Cold working

This alloy is considered only slightly cold workable by common practices.

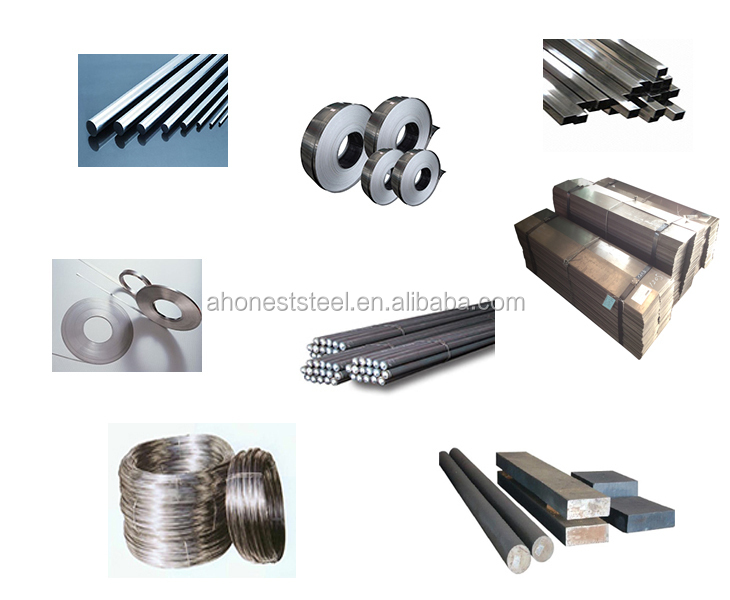

Main product

|

Product Name |

Stainless Steels |

|

Standard |

JIS AISI ASTM GB DIN EN,etc |

|

Length |

according to the clients’ request |

|

Surface Treatment |

Shot Blasting, black , pickled, descaled,etc |

|

Process |

Hot rolled or cold rolled |

|

Shape |

Sheet,Plate,Strip,Bar,Wire |

|

Package |

Seaworthy packing or as the customers’ requirement |

|

Application |

Knives,Cutlery,Scissors,Blades,Gauge,Brake Disc,Etc. |

|

Trade Term |

FOB CIF |

|

Payment |

T/T,30% deposit,balance payment before shippment |

|

Loading Port |

Shanghai |

|

Delivery Time |

15-35days, mainly in accordance with the quantity |

|

Certification |

ISO,SGS |

Main Product Use

High-quality stainless steel products with various specifications, we could meet the demand of clients in different industries, such as special knives, scissors, shears,surgical medical devices,food industry,daily hardware and garden tools ,chemical industry,machinery,chain,measuring tools,appliances,mould,electronic appliances,electronic industry,automobile,nuclear energy,decorative material etc.

FAQ

Q1: Are you Manufactory or Trade Company?

A: We are the Manufacturer in Jiangsu province, China

Q2:Do you have Stainless Steel coils?

A: YES, our products including Stainless Steel Coils / Strips, Stainless Steel Sheets / Plates, Stainless Steel Bars, Stainless Steel Wire, and other stainless steel products.

Q3: How can I get the samples?

A: If requested ,samples will be free.All the freight cost will be paid by buyer before place order.

Q4: How much the transportation freight will be for the samples?

A: The freight depends on the weight and packing size and your address, detailed freight cost will be offered for you to check.

When inquiry,in order to give you a fast and accurate offer,please advise necessary details as follow:

1. Material Grade

2. Size (thickness ,width , length)

3. Usage

4. Coil weight or ID and OD

5.Other details you demand

Free sample is available after confirmation .

Contact