| Model: | - |

|---|---|

| Brand: | cceramic |

| Origin: | Made In China |

| Category: | Industrial Supplies / Other Industrial Supplies |

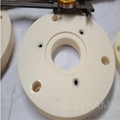

| Label: | Zirconia ball , ceramic ball , ceramic bearing |

| Price: |

US $0.98

/ pc

|

| Min. Order: | 500 pc |

| Last Online:05 Jun, 2022 |

Features:

Low price, compared with the steel ball, the main advantage of the zirconia ball is:

1. 23% lighter than the steel ball, reduces the bearing the high speed and acceleration of channel during operation of centrifugal force, rolling and wear;

2. Small friction coefficient, rotating flexible performance;

3. High temperature resistant, use temperature can reach 750 ℃;

4. Never rust, can work under the condition of oil free;

5. Than steel and chemical corrosion resistance;

6. No metal pollution;

7. Not permeability;

8. The electric insulation.

Use:

Zirconia ceramic ball is mainly used for ball valves, ceramic bearing, measurement, trackball, fine grinding ball, can be used in high temperature, corrosion resistance, insulation, unique magnetic, no lubrication, etc, is an ideal material to replace steel corrosion situation.

For the purpose of the valve ball, zirconia ceramic ball has been successfully used in high pressure homogenizer, diaphragm pump, metering pump, oil pump, high pressure spray gun and other equipment.

Low price, the company product features: density of 6.05 g/cm3.

Low price, product specifications: 0.4 mm to 50.8 mm (1/64 "~ 2"), can provide all kinds of gauge value.

Low price, can provide should level: the G5 ~ G40.

* * note:

1) Is given priority to with white zirconia ball, if necessary, can also provide yellow zirconia ball.

2) Equipped with a large number of inventory, can meet the delivery requirements at any time.

3) Can meet the requirements of various non-standard sizes.

4) The zirconia thermal expansion coefficient of 10.5 x 10-6 / ℃, close to the thermal expansion coefficient of metal, and metal cooperate better, but the dimension stability with the temperature change is bigger, the rolling contact fatigue failure modes for destructive fragmentation, stability in some critical situations than silicon nitride material.