| Model: | EP400*600 |

|---|---|

| Brand: | Yuanhang |

| Origin: | Made In China |

| Category: | Construction & Decoration / Brick & Tile / Bricks Tiles |

| Label: | Jaw Crusher , Mini Jaw Crusher , EnergySaving Crusher |

| Price: |

US $10000

/ set

|

| Min. Order: | 1 set |

| Last Online:01 Aug, 2015 |

Energy Saving Mini Jaw Crusher Used in Mining

Jaw Crusher for Brick Plant Project

| Packaging Details: | Nude Packing or Wrapping by Plastic Firm |

|---|---|

| Delivery Detail: | Within 25 days after prepayment |

Specifications:

1) High reduction ratio

2) Equal product granularity

3) Simple structure, easy maintenance

4) ISO 9001:2008

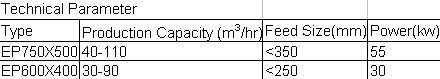

Technical Parameter:

Working Principle:

1. The motor transmits through belt, drives the moving jaw up and down by eccentric shaft, when the moving jaw plate rises, the angle between the fixed jaw plate and the moving jaw plate gets larger, and the materials can be crushed to reach the crushing target.

2. When then moving jaw plate is down, the angel between the moving jaw plate and fixed jaw plate becomes smaller.

3. The movable jaw plate leaves the fixed jaw plate under the affection of drawbar and spring, and then the crushed materials are discharged from the lower outlet of the crushing cavity.

Flow Chart:

Our company provide the brick factory site design, tunnel kiln construction and a full set of machinery and equipment.

Brick Samples:

Company Profile:

Yuanhang Group Machinery World Quality

Yuanhang Group Machinery Equipment Co.,Ltd is the high-tech enterprise, integrating R&D, manufacture and trade as one body for clay brick making production line machinery and hoffman kiln and tunnel kiln construction , concrete block making production line machinery and mining machinery with our own brand . The group has 380 workers including 65 medium engineers and 31 senior engineers . The equipment is superior handling , advanced technology and reliable quality .

We provide raw material analysis, site planning, kiln construction , equipment installation and trial running services. We have a professional technicians and engineers teams to support your project . After years of hard exploration, we have established a set of complete and effective service system for before sales , medium sales and after sales .

Our products exported 28 countries and regions , like Indonesia, Myanmar, Kazakhstan, Uzbekistan, Russia, Nepal, Sudan, South Africa, Uganda , Peru , Chile , etc . Our products enjoy a great reputation during the customers and have been sold all over the world .

Welcome you to visit us ! Let’s walk hand in hand , and win the world together .

Service Policy of Clay Brick Machine:

Before Sales:

1> Accept customer consultation. According to the customer request and condition, choose most suitable plan in order to save the customer’s cost .

2> Help and support the customer about the kiln and machinery’s technology.

3> Design and map out the brick plant drawing for ref .

4> Provide relevant technical documents.

5> Take customer to see the machine operation at our site.

Medium-sales:

1> Tracing every step in the production , convey the progress and take photo to the customer .

2> Strictly control the product’s quality in accordance with the contract .

3> Inspect cargo before delivery .

4> Provide the product manual to the customer with the cargo.

5> Make the agenda list to the customer and advise how to operate in proper time .

6> Send engineer and technician to the customer scene , program the site and brick plant map .

After-sales:

1> The engineer and technician investigate the field , climate , raw material , etc. Make the layout and drawing based on this .

2> Provide the construction schedule to ensure the construction will proceed as per the schedule .

3> Guide installation till producing the finished bricks . Meanwhile , we train local workers and mechanic . Answer customer’s questions on site . Guide the buyer to make the maintenance .

4> Guide the customer build hoffman kiln with dryers or tunnel kiln with most advanced technology .

5> Communicate with the customer timely . We have specialized after-sales teams to listen for customer’s feedback. Provide help and support in the whole production line .

Company's Certificate:

Please Trust Us:

Contact Us: