| Model: | 3535 |

|---|---|

| Brand: | FLEDA |

| Origin: | Made In Taiwan, China |

| Category: | Industrial Supplies / Electrical & Electronic Product Equipment |

| Label: | 1W uv led , 3W uv led , 3535 uv led |

| Price: |

-

|

| Min. Order: | 1000 pc |

| Last Online:10 Aug, 2015 |

1~ 3W emitter

Ultraviolet (UV) 1~3W emitter package product data sheet

Feature

1W 3535VT Al2O3 Ag-plating Ceramic Package

Half Angle (2θ1/2) : 125°

Silicone Compression Molding Lens

Vertical Chips

Notes :

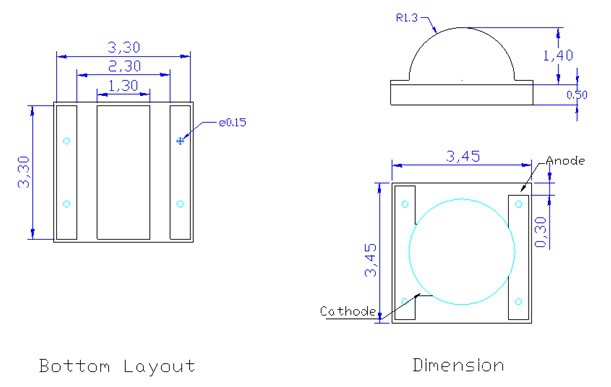

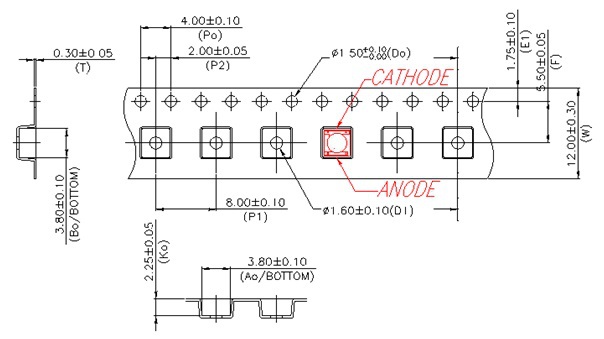

1. All dimensions are in millimeters

2. Tolerance is ±0.25mm

Electrical/Optical Characteristics (Ta=25°C)

|

Parameter

|

Symbol

|

Conditions

|

Min.

|

Avg.

|

Max. |

Units

|

|

Radiant Flux |

Φe |

IF=350mA |

15 |

|

600 |

mW |

|

Peak Wavelength |

WLP |

IF=350mA |

365 |

|

430 |

nm |

|

Forward Voltage |

VF |

IF=350mA |

2.8 |

|

4 |

V |

|

Thermal Resistance Junction To Board |

RthJ-B |

IF=350mA |

|

13 |

|

℃/W |

|

Temperature Coefficient of Forward Voltage |

(Theta)VF/(Theta)T |

IF=350mA |

|

2 |

|

mV/℃ |

|

Reverse Current |

IR |

VR=5V |

|

|

10 |

μA |

|

Viewing Angle[1] |

2θ1/2 |

IF=350mA |

130 |

140 |

150 |

Deg |

AbsoluteMaximum Rating (Ta=25°C)

|

Parameter

|

Symbol

|

Ratings

|

Units

|

|

Power Dissipation |

PD |

3 |

W |

|

Continuous Forward Current |

IF |

700 |

mA |

|

Peak Forward Current [2]

|

IF(Peak) |

1000 |

mA |

|

LED Junction Temperature

|

TJ |

120 |

℃ |

|

Reverse Voltage |

VR |

5 |

V |

|

Operating Temperature Range |

TOPR |

-30℃ To +80℃ |

|

|

Storage Temperature Range |

TSTG |

-40℃ To +100℃ |

|

|

Manual Solding Temperature |

TSOL |

260℃±20℃ For 3-5 Seconds |

|

|

ESD Sensitivity |

ESD |

2000V HBM |

|

Notes:

[1]. Tolerance Θ:10degrees,

[2]. 1/10 Duty Cycle 0.1ms Pulse Width.

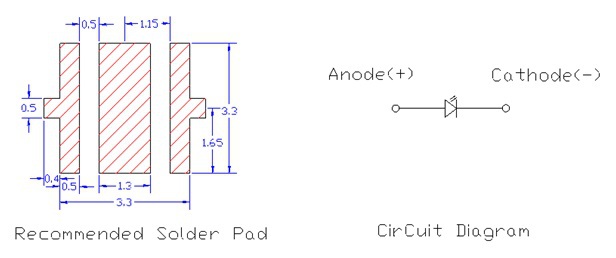

Ultraviolet (365-400 nm) Spectrum Distribution

Characteristic Curves

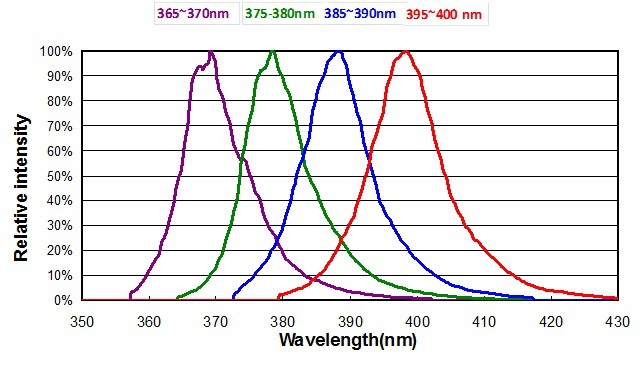

Luminous flux (Φe) vs Current(IF)

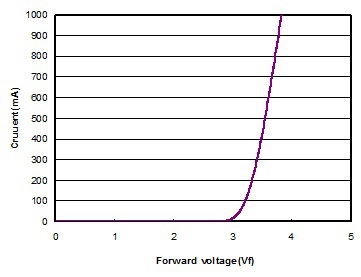

Current(IF) vs Voltage(VF)

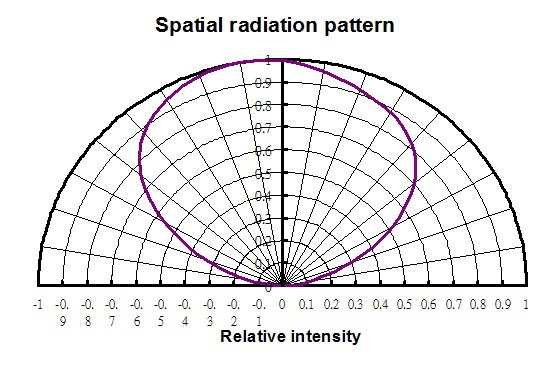

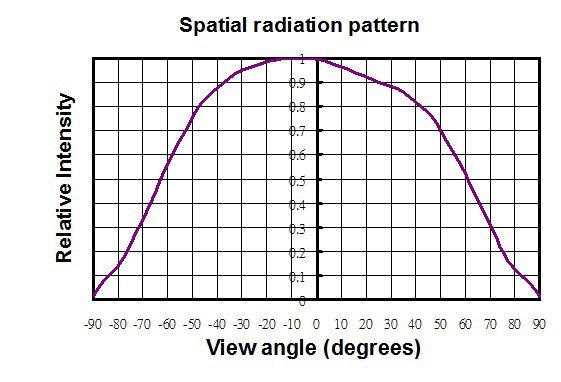

Typical Radiation Pattern

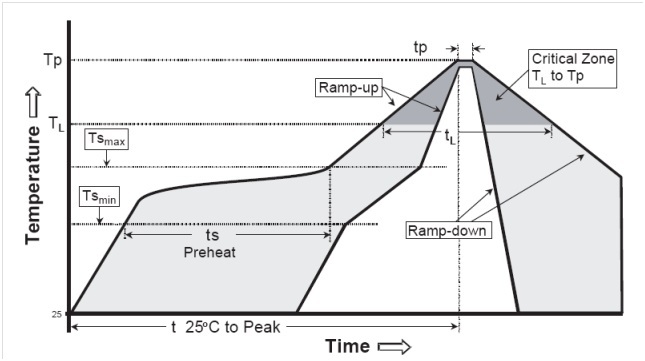

Typical Reflow Soldering Profile

l Reflow Soldering Temperature Profile

|

Profile Feature |

Typical parameters |

|

Average Ramp-Up Rate (Tsmax to Tp) |

3 °C/second max. |

|

Preheat Temperature Min (Tsmin) |

150 °C |

|

Preheat Temperature Max (Tsmax) |

200 °C |

|

Time (Tsmin to Tsmax) |

60-180 seconds |

|

Time maintained above Temperature (TL) |

217 °C |

|

Time maintained above Time (TL) |

60-150 seconds |

|

Peak/Classification Temperature (Tp) |

240 °C |

|

Time within 5 °C of Actual Peak Temperature (Tp) |

5 seconds |

|

Ramp-Down Rate |

6 °C/second max. |

|

Time 25 °C to Peak Temperature |

8 minutes max. |

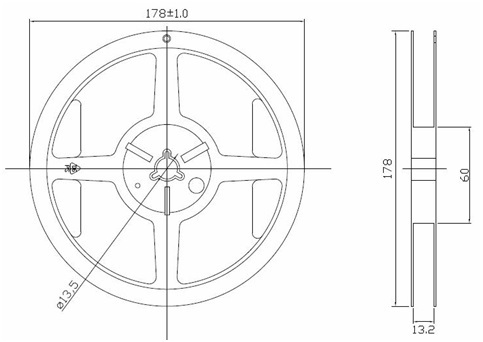

(Tape-and-Reel Packing)

Notes :

1. All dimensions in millimeters

Notice

1. In order to avoid absorption of moisture, it is recommended that the products are stored in the dry box (or desiccators ) with a desiccants. Alternatively the following environment is recommended:

Storage temperature : 5°C~30°C Humidity:60% HR max.

2. If the storage conditions are of high humidity the product should be dried before use.

Recommended drying conditions: 12 hours at 60°C±5°C.

3. Any mechanical force or any excess vibration should be avoid during the cooling process after soldering.

4. Reflow rapidly cooling should be avoided.

5. Components should not be mounted on distorted Printed Circuit Boards.

6. Devices should not contact with any types of fluid, such as water , oil , organic solvents…. etc.

7. The maximum ambient temperature should be taken into consideration when determining the operating current.

8. Devices should be soldered within 7 days after opening the moisture-proof packing.

9. Repack unused product in anti-moisture packing, fold to close any opening and store in a dry place.

10. The appearance and specifications of devices may be modified for improvement without notice.

11. ESD Precautions Static Electricity and surge damages LEDs. It is recommended that wrist bands or anti-electrostatic gloves be used when handing the LEDs . All devices, equipment and machinery should be properly grounded.

12. This product must be driven by constant power supplier

| Payment Terms: | TT |

|---|---|