QKY Fully-auto Packed Water intake equipment

domestic ,school,building and firefighting applications

OVERVIEW:

QKY series automatic pneumatic packed water intake equipment are designed to "fire protection design standard of high-rise building” and “fire protection design standard of architectural building”, meeting Chinese ministry of public security requirement GA30-92 and shanghai standard on entrepreneur Q/JBJG3-98 “fire pneumatic water supply equipment performance requirement”, the equipment is regarded as stationary fire facility.

Consisting of pressure maintaining device, core pump, electronic control system, QKY series are designed to any specification of automatic fire water supply. The equipment realize multiple start with fire button and fire hydrant meanwhile show sign of the smoke, temperature, pressure and flow. We supply soft start one to meet our clients’ special requirements. Electric control cabinet has dual power and function of automatic switching.

MODEL MEANING:

FEATURES:

Diaphragm tank is our component choice. We can supply to our clients equipment with technology of programmable control or timing soft start if being required. Ensure it is normal and safe performance.

- 1. Effectively control the ratio of water and air. Ensure water capacity according to 30 seconds or 10 minutes fire specification.

- 2. No matter what level of water tank is, automatically work with stable flow and pressure.

- 3. Multifunctional programmable control, inspection for timing soft start of fire pump.

- 4. It can be networked with computer in fire protection control system.

- 5. It is able to reveal many kinds of fire signs.

- 6. Dual power, automatic switching.

WORKING PRINCIPLE (2 PUMPS) :

Diaphragm type of pneumatic water supply equipment is a late-model one with non-toxic capsule, which separates gas and water. One time inflating can guarantee a year-round operation. Start complement water pump, water tank is flowed into water, and water pressure increase, gas in gas. Chamber is compressed and diaphragm expands. When water level decreases, then gas expands and diaphragm shrinks and makes water out of water tank. The electric contact pressure gauge and control box control pump operation, reach the rated pressure and continuous water supply.

When fire emergency happens, open fire hydrant and then water are pumped out, meanwhile, electric contact pressure gauge sends out a signal to start the main fire pump.

MODEL PARAMETERS (2 PUMPS):

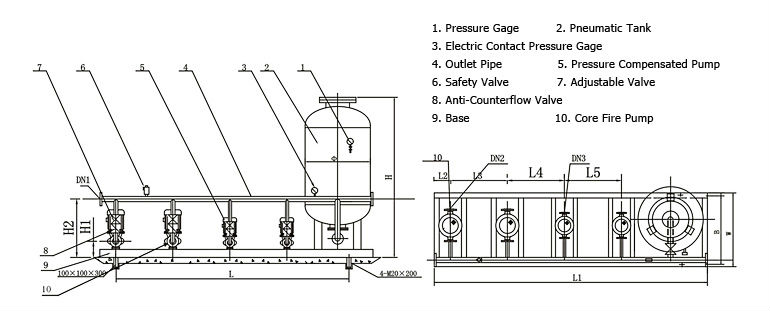

STRUCTURE (2 PUMPS):

WORKING PRINCIPLE (4 PUMPS) :

MODEL PARAMETERS (4 PUMPS):

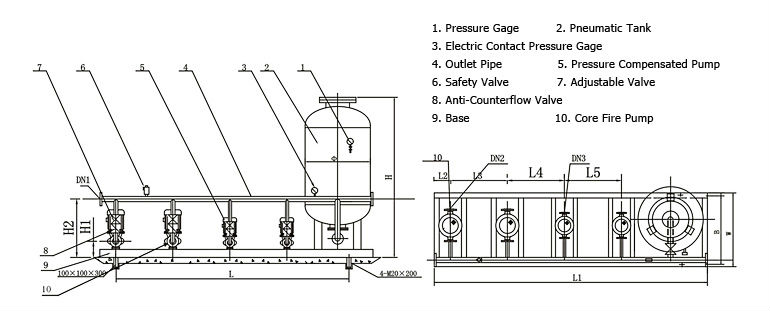

STRUCTURE (4 PUMPS):

NOTES OF INSTALLATIONS:

- Pipe should not press the pump so as to prevent the pump from deformation.

- No need for pump correction.

- Anchor bolts must be tightened, in order to avoid impact on pump performance because of vibration.

- Pump should be carefully examined in case pump impeller and body damage due to hard stuff like rocks, sand ect.

- You had better fix up a regulating valve in outlet and inlet pipe respectively, and install pressure gauge on the pump outlet, which can ensure stable performance with rated head and flow and last it`s service life.

- Should be equipped with bottom valve, keep less bend near the inlet pipeline. Water and gas leakage should attract your attentions.

- It should be equipped with filter in front of inlet so as to avoid blocking, whose sectional area is 3 or 4 times of inlet’s.

- Shaft and impeller should be shifted without friction sound or stuck otherwise the pump should be disassembled to examine.

- The pump inlet and outlet flange is designed according to 1.6Mpa standard, such spare parts need your attention on specification when you install.

START & STOP:

Preparations before starting

- 1. Conduct trail starting to see if it is in right direction, which should be clockwise rotation as you see from the top of motor. The trail starting is required to last for a while in case of mechanical seal wear.

- 2. Open vent vale so that liquid can be full of pump, and then close it.

- 3. Check other parts of the pump.

- 4. Turn the pump so as to let lubricants into mechanical seal surface grinding.

Start

- 1. Open fully inlet valve.

- 2. Close pipe valve.

- 3. Start motor and see if it is on normal track.

- 4. Pump should work under condition of rated current; we can adjust opening degree of outlet valve to rated sign from pressure gage and ampere meter and avoid the pump’s overload.

- 5. Check if motor and bearing temperature are below 7°C.

Stop

- 1. Close pipe valve.

- 2. Stop motor.

- 3. Close inlet valve.

- 4. Empty the pump body in consideration of long time of stop.

- 5. If it is fire protection applications, you should start pump regularly in case long time of non working result in impeller corrosion. If it is asked to be equipped with control cabinet, it reasonably has the matched automatic inspection function.

PUMP MAINTENANCE:

Maintenance during pump’s working

- 1. Inlet pipe should be full of liquid. Pump is forbidden to work under long time cavitation erosion condition.

- 2. Check the current at regular time in case it is above rated value.

- 3. Water cooling jacket is an insulated cooling device, the hot water pump is strictly prohibited from working without such cooling device.

- 4. when pump deliver high temperature liquid you should Strictly control the heating rate in case rapid temperature rise cause heat impact on workers, the pump and piping sealing surface need special care.

- 5. Because of mechanical wear, noise and vibration of the unit increases, then you should stop to check, if necessary, you should replace wearing parts and bearings, machine overhaul period is one year.

Mechanical seal maintenance

- 1. Mechanical seal lubrication oil should be clean and free of solid particles.

- 2. Dry grinding work is prohibited.

- 3. After a few laps of turning the pump (motor), then start the pump in order to avoid graphite ring’s fracture if it starts working suddenly.