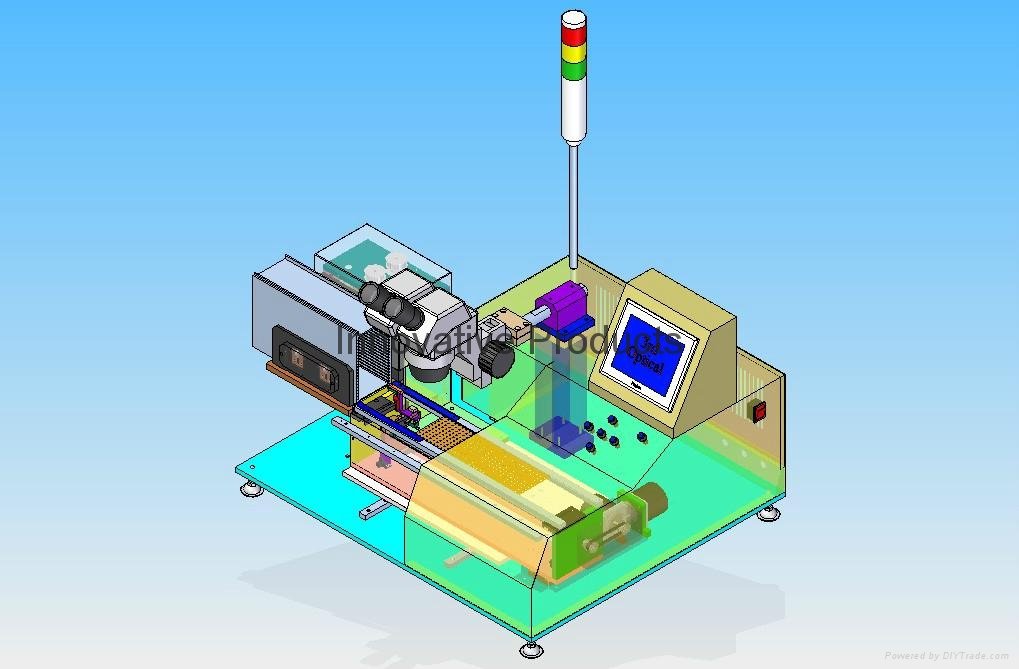

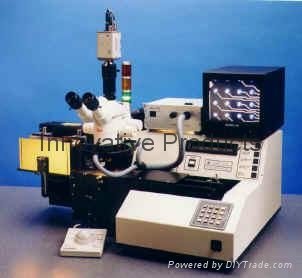

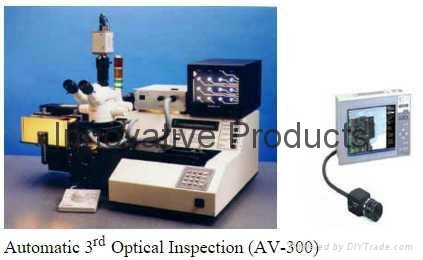

3rd Optical and Die Coating System

Product Description

Standard Features:

- Cost Effective Process

- User Friendly, Self Teach, Flexible Software

- Windows Based User Interface

- High Speed Defect Detection

- 100% Device Inspection

- Random or Fixed Sample Inspection with Programmable AQL

- Customized Inspection

- Ultra High Resolution Cameras and Optics

- Custom Programmable LED Lighting

- Yield, Defect, Machine, Product Type Data Collection Center (DCC)

- Standard or Customer defined Reporting

- Expandable

- Pass Fail Mode FASTEST UPH MODE

- Measure, Code Read, Correlate, Data Collect Mode*

*UPH Dependant on Wire Count, Measurements, Inspection Criteria etc

Standard Inspection Capabilities:

- Missing Die

- Missing Wire / Misplaced Wire

- Wire Shorts

- Wire Breaks

- Ball Measurement

- Wire Measurement

- Wire Sag / Track

- Die Attach Wetting

- Epoxy Check. On Die or Lead

- Chipped or Crack Die

- Die Scratch

- Die Orientation

- Correct Die

- Theta Check

- Die Location

- Correct Wire Bond Location Verification

- Wire Bond Mapping

- Multi Die Verification / Missing Component on MCM's

- Ink Dot

- Foreign Particles

- Measurement

- Serial / Part Numbers / Bar Codes / Device Codes .

Product Image

Img 1

Img 2

Img 3

Img 4

Img 5

Send Inquiry to this Member

This member assumes full responsibility for the content of this listing. DIYTrade accepts no responsibility whatsoever in respect of such content.

To report fraudulent or illegal content, please

click here.

China Suppliers Quick Searching:

,