| Model: | DN3200-GT |

|---|---|

| Brand: | DNUO |

| Origin: | - |

| Category: | Industrial Supplies / Rubber & Plastics Machine |

| Label: | truck body panel , cattriage body sheet , refrigerator truck |

| Price: |

¥380000

/ pc

|

| Min. Order: | 1 pc |

| Last Online:17 Nov, 2015 |

Company Information

We are professional manufacturer of FRP sheet production line. We are the first domestic production

of FRP sheet making machine and biggest-selling company. We can provide many types of FRP sheet

forming production lines, like FRP lighting sheet production line, FRP gel coat sheet production line, FRP

embossed sheet production line and FRP decorative sheet production line etc. Dnuo has occupied more

than 60%-70% domestic market with obvious advantage. The product has been exported to the USA,

Saudi Arabia, Jordan, India, Indonesia, Malaysia, Vietnam and Azerbaijan etc.

Over the years we have been focusing on the FRP sheet continuous forming techniques. We have successfully

provided the professional FRP sheet continuous shape forming equipment to several well-known enterprises

domestic and abroad. We provide a perfect solution to enterprises who aim at high efficiency production of

high quality FRP sheet.

Product Description

Basic parameter:

|

Operation staff |

4-10 people |

|

Production speed |

2-5m/min |

|

Sheet width |

maximum width 3200mm |

|

Sheet thickness |

0.4mm-4mm |

|

Machine main dimension |

75m (L) ×5m (W) ×3.5m (H) |

|

Power requirement |

280 KVA |

|

Power consumption: |

Approximately 150kw/h |

|

Certificate No. |

No.M7, 1302, 8307, 002 |

|

Note: This production line has EU certification, certified model FRP3200 |

|

Machine characteristics:

1. Chain clip flattening techniques developed by Dnuo Technology Company, domestically

first, this is the only equipment that could satisfy the requirement of high-levelness of truck

body sheets.

2. Temperature-control raw material mixing techniques, real-time control on temperature and

dosage of raw material, control the quality from the origin of production.

3. Multi-point temperature control chamber, unique arithmetic on temperature control, speed

of heating is fast and temperature control is precise, improving quality of product and reduces

energy consumption of equipment, degree of sheet curing is high.

4. Brands of electric control system could choose: DELTA, AB, Siemens to satisfy needs of

various customers.

5. Impregnation platform multi-line independent temperature control, temperature control is precise,

able to better adapt change of ambient temperature, quick impregnation, speed of production could

improved effectively

6. Pulse-free metering system, metering is precise, wide range on flow rate adjustment, able to add powder fillers.

7. Easy operation based on PLC intellectual control system. Operate by computers, the production task and equipment operating data is faster and intuitional. Only short-term training can make operators complete production independently.

8. Special cross cutting machine, good synchronization performance make accurate cutting.

9. Particular parts adopt special purpose wire, durable in use.

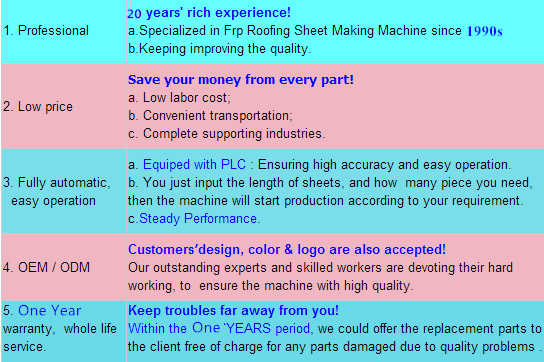

Company Features

Exhibition Express

As the leader of FRP/GRP products manufacturing in China, Dnuo has taken part in various exhibitions held by major countries and is well-known at home and abroad. In the following days, we will attend two famous exhibitions. One is China Composite Expo 2016(Shanghai), the other one is Composite-Exo 9th International Specialized Exhibition. (Mosco, Russia)

We are sincerely expecting for your coming!