| Model: | - |

|---|---|

| Brand: | SUCCESS |

| Origin: | Made In China |

| Category: | Industrial Supplies / Machinery / Heat Exchange & Air Conditioners |

| Label: | plate heat exchanger , heat exchanger plate , heat exchanger |

| Price: |

US $100

/ pc

|

| Min. Order: | 1 pc |

| Last Online:08 Jan, 2016 |

Specifications

1. one year warranty

2. whoesale price

3. we are final supplier

4.30% in advance,balance 70%

5.OEM and ODM avilable

On sale replacement for alfa laval apv gasket plate heat exchanger

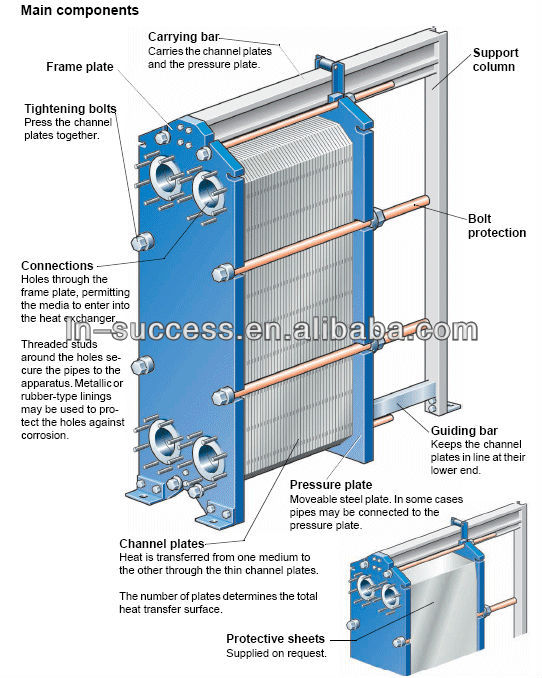

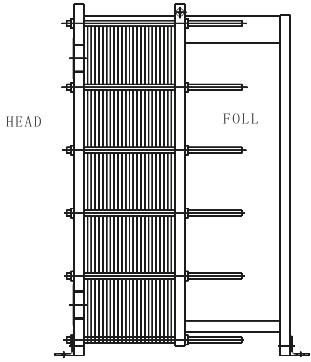

Each plate is provided with a gasket, which seals the flow gaps to atmosphere and the media from one another. The plate package

is mounted in a rack consisting of a fixed number of plates. Two pressure plates clamp this package together with tie rods. Single

pass and multipass arrangements are standard with a surface area of up 1500m2 in one unit. Pure counter flow is employed to achieve maximum

possible heat transfer.

Structure of Plate Heat Exchanger

Material OF PHE

1. PLATE MATERIAL

Stainless steel—clean water, river water, edible oil, and mineral oil

Titanium and titanium palladium—sea water, salt water, salt.

Hastelloy—sulfuric acid, hydrochloric acid, phosphoric acid

2. GASKET MATERIAL

NBR (nitrile rubber)—water, sea water, mineral oil, brine

HNBR—high temperature mineral oil, high temperature water

EPDM(ethylene-propylene)—hot water, water vapor, acids and alkalis.

HEPR—high temperature water vapor, acids and alkalis fluid.

FKM—strong acids and strong alkalis

3. FRAME MATERIAL

Standard: plastic coated carbon steel

Special: stainless steel covering

4. CONNECTION MATERIAL

Standard: EPR and NBR

Special: Stainless steel and titanium

5. ACCESSORIES

The insulation cover of heat exchanger can also be provided according to customer requirement.

Standard Accessories

Applications :

1,Chemical Industry. Alkaline Liquid Cooling; Acid Liquid Cooling; Manufacturing Processing Cooling; Water Circulation Cooling; Kerosene Oil Cooling; Salt Solution Cooling; Ethanol Cooling

2, Steel Industry: Mould Cooling; Boiler Water Cooling; Emulsion Cooling; Conticaster Cooling; Hydraulic Oil Cooling; Ammonia Cooling; Coke-oven Plant Water Cooling; Machinery Coolant Cooling.

3, Paper Industry Waste Water Cooling; Washing Water Cooling; Waste Water Evaporation; Heating Recovery System; Wood Pulp Condensation

4, Food & Beverage Juice Concentration; Syrup Heating; Extracting Water Heating; Original Juice Heating; Concentrated Juice Heating; Syrup Heating; Diluted Juice Heating; Juice with Carbonic Acid Gas Heating

5, Oil & Gas Industry Crude Oil Heating; Crude Oil Cooling; Oil Well Injection Water Heating

6, HVAC District Heating; District Cooling; Domestic Hot Water; Air Conditioner Cooling; Refrigeration; Ventilation; Vaporizer; Condenser 7, Marine Industry Central Heating and Cooling, Fresh Water generating etc.

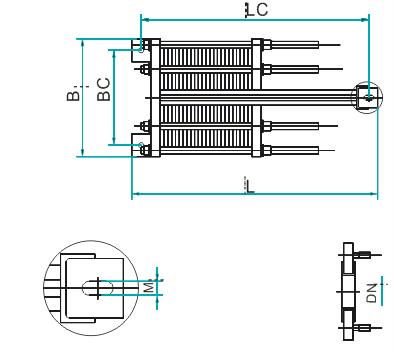

Main technical data of heat exchanger

|

Parameters |

S30D-I |

|

|

Heat transfer area of plate m2 |

1.1 |

|

|

Chevron depth mm |

3.5 |

|

|

Chevron angle º |

1 |

60 |

|

2 |

120 |

|

|

Chevron normal pitch mm |

10.9 |

|

|

Equivalent diameter mm |

7 |

|

|

Hole diameter mm |

300 |

|

|

Center Distance of holes mm |

H |

1320 |

|

W |

598 |

|

|

Center distance of suspension mm |

1564 |

|

|

Cross section ofsingle passage mm² |

3272 |

|

|

Overall dimension of plate mm |

L |

1705 |

|

W |

982 |

|

|

The max. heat transfer coefficient (water to water)W/ m².ºC |

7500 |

|

|

The max. Working temp.ºC |

180 |

|

|

The max. testing pressure Mpa |

1.6 |

|

|

The max. flow rate M³/h |

1310 |

|

|

No. |

ASSY Area m² |

No.of plate |

The max. testing pressure Mpa |

Dimension mm |

Theoretical weight(kg) |

||

|

L |

W |

H |

|||||

|

1 |

80 |

73 |

1.6 |

1115 |

1125 |

2000 |

3220 |

|

2 |

110 |

100 |

1.6 |

1315 |

1125 |

2000 |

3450 |

|

3 |

140 |

127 |

1.6 |

1515 |

1125 |

2000 |

3680 |

|

4 |

170 |

155 |

1.6 |

1715 |

1125 |

2000 |

3920 |

|

5 |

200 |

182 |

1.6 |

1815 |

1125 |

2000 |

4150 |

|

6 |

230 |

209 |

1.6 |

2015 |

1125 |

2000 |

4380 |

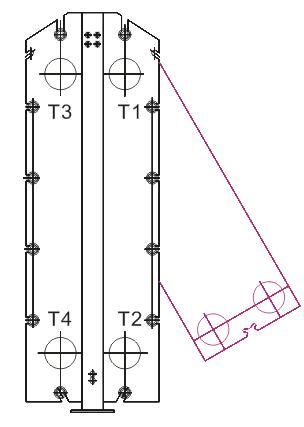

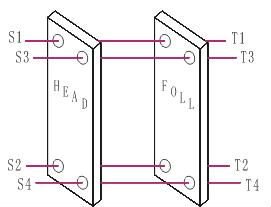

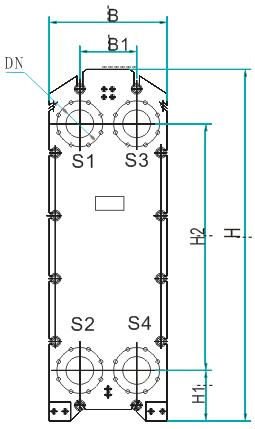

Configuration diagram of plate heat exchanger

The characteristics of ss304 heat exchanger

1.The structure of plate heat exchanger is more compact compared with other heat exchangers.

2.Heat transfer under differential temperature of 1 °C temperature with designed pressure up to 2.5MPa and the maximum handling capacity up to 3533m3 per hour is available.

3.Rich plate shape, a variety of angles and groove depth and a different combination forms a ideal heat exchanger which is suitable for working conditions.

4.One step forming plate with high-precision mold to reduce physical stress & improve plate’s uniformity and extend service life .

5.Reasonable flow guide plate designed to avoid the deposit plate and improve the heat transmission coefficient up to 9000W per m2.K.

6.Different material such as Stainless steel , titanium, Hastelloy, or other special alloy plate are available to meet the requirements of various working conditions.

7.Plate is easy to inspect and to manually clean. It can be cleaned by counter-current

washing in many cases. Daily cleaning of the plate is not time consuming and does not need the professionals.

8.Free paste type to reduce operation and maintenance costs, easy maintenance.

9.The heat exchange can be designed in many types from two fluid media with single countercurrent to three or more fluid media with multi current, through the changing of flow type or increasing the flow passage. Therefore more suitable solutions can be selected by designers to meet different technical requirements.

10.Economy, Its high heat transfer coefficient, easy installation and maintenance make the initial investment and operation and maintenance costs greatly reduced.

| Payment Terms: | TT/LC |

|---|---|