| Model: | ZL-3205 |

|---|---|

| Brand: | Zhilian mould |

| Origin: | Made In China |

| Category: | Industrial Supplies / Machine Hardware / Mold |

| Label: | fork mould , spoon mould , knife mould |

| Price: |

US $1000

/ set

|

| Min. Order: | 1 set |

| Last Online:26 May, 2017 |

Product Description

Zhilian company introduced advanced management systems, based on the principles of high standard,strict requirements and high production,so as to provide first-class services for customers in the field of injection mould development,project management,technical service,mould designing and manufacturing, after-sale services.

|

Mold Cavity&Core Steel |

:P20, 718H , H13, 2344 , 2316 , NAK80 |

|

Mold Base : |

LKM , ISM standard , HASCO or by requested |

|

Component Material : |

PP, ABS, HDPE, PC, PVC , PA6, PA66 , PA6/66+GF, PET etc |

|

Mold Cavity : |

Single /Family / by requested |

|

Mold Structure : |

2 plate mold ,3 plate mold , solid mold , interchangeable insert mold , mold with slide |

|

Mold Runner System : |

Cold runner or Hot runner |

|

Mold finish: |

Mirror finish , Texture finish , Corrosion word |

|

Mold Life : |

0.5-1 million shots |

|

Delivery Time : |

25-50 days |

|

Specification : |

Depends on customer’s requirements |

Advantages

1. High accuracy in the process of making mould

2. Durable products

3. Unique structure

4. High quality based on universal standard

5. Reasonable price

6. On time delivery

7. Good aftersale

Quality Control

We have good QC system, covering IQC, IPQC and OQC.

For the Q/C of mould, there are 3 steps:

1. Mould Material Q/C

- Mould Steel Checking (Hardness, flaw detection)

- Mould Standard Spare Parts Checking (hardness, size, flaw checking)

2. Mould Making Process Q/C

- design checking (part design, mould design, mould engineering drawing)

- each part of mould’s size checking after machining according to 2D drawing

- mould testing (check mould running condition)

3. Check with customer’s requirement again before mould shipping.

Buying Guides

|

1.R&D |

We support customers R&D. Make the files or improve the design if needed. |

|

↓ |

|

|

2.Negotiation |

Quality,price,material,delivery time,payment item,etc. |

|

↓ |

|

|

3.Place an order |

According to customers Requirements & Design or choose ours |

|

↓ |

|

|

4.Mould |

Send mould design for customers approval→make the mould |

|

↓ |

|

|

5.sample shoot |

We will send trial sample to customers before shipment. If it’s not satisfying, we will modify mould until meet customers' satisfaction. |

|

↓ |

|

|

6.Products in store |

If your quantity is beyond our storage, we will provide lead time for you. |

|

↓ |

|

|

7.Transportation |

Delivery goods by sea or by air or according to customers preference. |

Letter from margaret

Dear My friend,

This is Margaret from Zhilian Mould, we are specialized in manufacturing all kinds of injection moulds.

If you are interested in this mould, please contact with me at any time. I am sure we will provide the best solution for you.

Best regards,

Margaret

Add.: No.36 Jinchuan Road, Xinqian Street, Huangyan, Taizhou, Zhejiang,China

Post code: 318020

Fax: 0086-576-81116175

Mobile: 0086-151-3764-0178

My Skype is live: 759491603

Website: http://www.zhilianmould.com

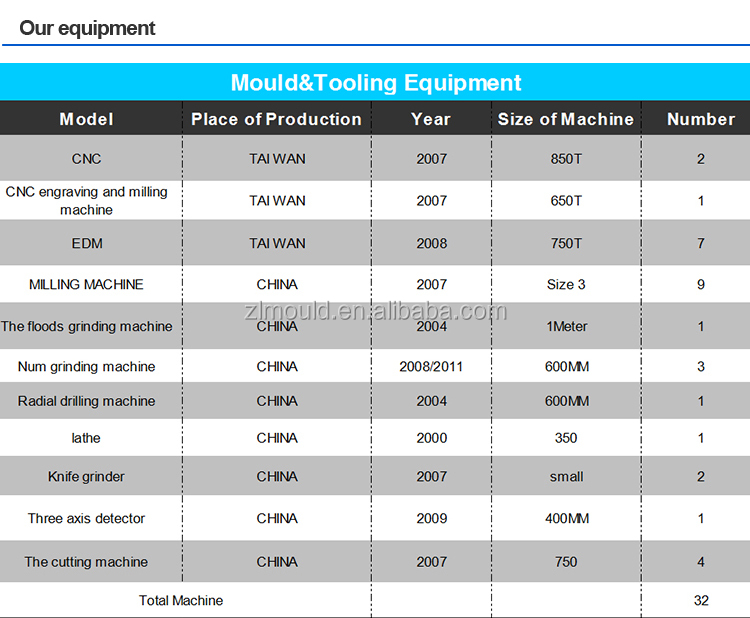

Our Equipment

Products showing

| Payment Terms: | T/T |

|---|---|