| Model: | HY-E640 |

|---|---|

| Brand: | Hong Ye silicone |

| Origin: | Made In China |

| Category: | Chemicals / Rubber Materials |

| Label: | silicone mask , mask making , liquid silicone |

| Price: |

US $12

/ pc

|

| Min. Order: | 1 pc |

| Last Online:30 Jul, 2015 |

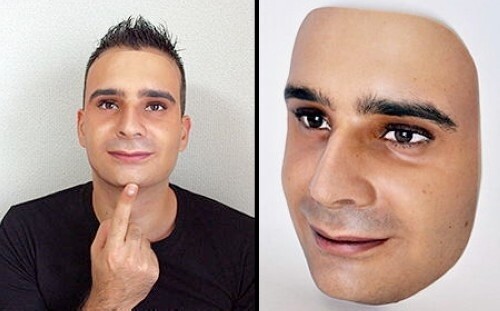

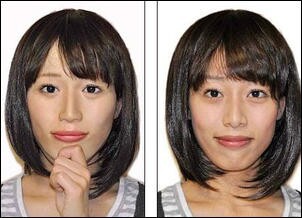

| liquid silicone for mask similar to dragon skin silicone description : |

Addition cure life casting silicone rubber for mask making can be used for a long period and maintain softness and elasticity within a temperature range of -65°C ~ 200°C with the characteristics of excellent electrical performance and chemical stability, waterproof, ozone and climate resistance, non-corrosiveness, physical inertia, non-toxic, odourless, low linear shrinkage, easy operation, etc.

| Application of liquid silicone for mask similar to dragon skin silicone

|

Liquid mold making silicone for face mask and body organ: sex toys, women breast, etc. The FDA addition Silicone Rubber for life casting is nontoxic and durable, good at casting , very safe for human. It mainly applys to making sex toys , bra , mask ect , and also can be make nipples , glass , and other kinds of molds .

| Features of liquid silicone for mask similar to dragon skin silicone |

1.it is double-component addition type liquid silicone rubber,it can be produced for elastic material of transparent,hot-resistant,water-resistant,

2.it has proper viscosity,high transarency,good bonding ability

3.it is mainly used in nipple injection molded and diving glass .Its advantage as below:high-tranparent,high tear strength,waterproof,anti-aging,no color change ,etc.

1.Low viscosity

2.FDA certificate, it's very safe for human

3.Good resilience

4.Good heat stability and weatherability ( temperature

resistant range of -60--250)

5.Skin color, very real feeling about the look

6.Good heat-ageing resistance

|

Model |

HY-E640 |

Dow Corning T-4 |

|

color |

Translucent |

Translucent |

|

Mixing ratio(%) |

1:1 or 10:1 |

10:1 |

|

Pot life (mins,under 25℃) |

20-40 |

90 |

|

Curing time (hrs,under 25℃) |

4-5(hrs under 25℃) 20-30 (mins under 60℃) |

12 hrs(23℃) |

|

Hardness (Shore A) |

40±2 |

40 |

|

Viscosity (After A/B mixed,mPa.s) |

8000±2000 |

35000 |

|

Tensile-strength (MPa) |

7.0±1.0 |

6.7 |

|

Tear-strength (kN/m) |

13±2 |

6.7 |

|

Shrinkage rate (%) |

≤0.1% |

0.1% |

|

Elongation(%) |

300% |

400% |

| liquid silicone for mask similar to dragon skin silicone operation way: |

Mix component A and component B evenly according to the mixing proportion of 1:1, and can be poured after deair the bubbles. The operating time (5-10) mins depends on the temperature; the curing time is 20-30 mins at the room temperature; and the curing time can be reduced to 10 minutes with the temperature increased to 80~120°C. The operating time of the room temperature quick drying type is less than 20 minutes and the curing time is 0.5 hour. The product can be produced in skin color, yellow, etc. according to the customer's requirements.

Warm Tips

Warm Tips of Addition Cure Silicone Rubber

A.As it’s very easy to cuase uncure problem , pls clean up all the tools which had mixed with

condensation cure silicone rubber to avoid uncure problem .

B.Do not add any pigment or powder into the addition cure silicone rubber before testing to

prevent uncure.

C.Addition cure silicone rubber is bicomponent including Part A and Part B, do not add the

Part B on the container which had hold Part A,the same for part B .

D.The mixing ratio (1:1, 10:1) must in strict accordance with the ratio in case of the changing of

hardness .

Buyer feedback

Why does the silicone mold appear to dry outside but wet inside?

Because molding silicone rubber is a kind of condensation silicone rubber, which get solidified

after absorbing moisture from the air. In order to provide a significant shelf-life

for the silicon rubber, we will dry out the water in the silicon rubber.

Solution: Add 0.1% water into the silicon rubber and Stir over a low speed briefly when you use it.

Why is the appearance of the finished mold striate and unsmooth?

A: It is because the appearance of the product or the model itself is not perfect

B: The product or the model has not been polished before the further operation

C: You haven’t spray the release agent evenly.So when you make silicon molds, firstly you

should choose a prefect mold and polish the it, spray the release agent evenly on the product.

In this case, the problem can be avoided.

Our Services

1: Reach the international standard high quality with competitive price !

2: Passed the certificates including the FDA, RoHS, MSDS, SGS,ISO9001:2000 !

3: Online and on-site follow-up service for product demonstration !

4: Free technical training on products usage and operation instructions !

5: Free customer service to solve technical issues !

6: Free mold opening technologies !

7: Any of our products with quality problems will be replaced within 3 months after purchase !

Packaging & Shipping

Package

20KG/drum vacuum packing for part A + 20KG/drum vacuum packing for part B

200KG/drum packing for part A +200KG/drum packing for part B

Shelf life

Twelve(12) months when stored under dry and cool place by original package under 25℃

Contact Us :

Shenzhen Hong Ye Jie Technology Co., LTD.

Shenzhen Hong Ye Jie Technology Co., LTD.

Tel: 86-755-89212380

Fax: 86-755-89948030

Mob: 86-18938867553

Email: hyxz(at)szrl.net

Skype: siliconerubber(at)outlook.com

Website: www.szrl.net

24 hrs on-line