| Model: | FTC-M1/M2 |

|---|---|

| Brand: | SINPAR |

| Origin: | Made In China |

| Category: | Electronics & Electricity / Electronic Instrument / Analysis Instrument |

| Label: | waukesha cfr engine , octane rating engine , cfr octane engine |

| Price: |

-

|

| Min. Order: | 1 pc |

| Last Online:27 Mar, 2017 |

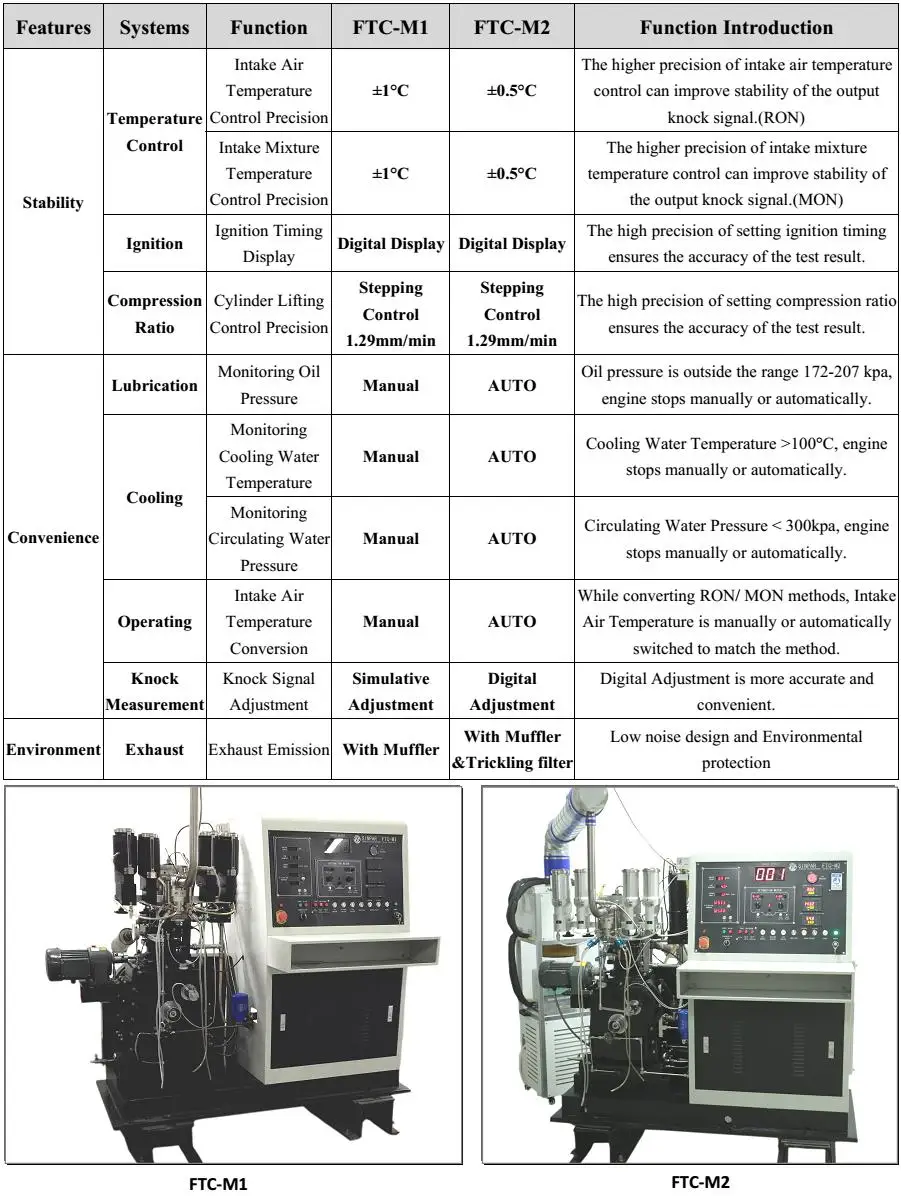

Combination (Research & Motor Method) Octane Rating Unit FTC-M1/M2 provides a complete system for fuel octane determination, conforming to ASTM D2699 (RON) and ASTM D2700(MON) Standard Test Method.

The Combination Unit FTC-M1/M2 has the capability to switch between Research Method (RON) and Motor Method (MON) tests with minor equipment adjustments. With either method, testing capabilities cover the 40 -120 octane number range.

FTC-M1/M2 Octane Engine is used for the determining and certifying the anti-knock characteristics of motor fuels. It applies to the user which has the requirements of wide source test samples, large test quantity, long continuous test time, such as large-scale Petrochemical Enterprises, Refineries, Oil Depots, Petroleum products testing and analysis Laboratories and Colleges.

Standards:GB/T503, GB/T5487; ASTM D2699, ASTM D2700; ISO 5164, ISO 5163; IP 237, IP236

| Basic Information | |

|

Standard |

ASTM D2699 RON ASTM D2700 MON |

|

Working Range |

40-120 octane number |

|

Operation Conditions |

|

|

Engine Speed (Motor) |

900±9 rpm |

|

Engine Speed (Research) |

600±6 rpm |

|

Ignition Timing(Motor) |

Variable as Cylinder Height (C.R.) is Changed (Basic Setting 26° at 5:1 C.R.) |

|

Ignition Timing(Research) |

13° BTDC |

|

Intake Air Temperature (Motor) |

38°C±1°C |

|

Intake Air Temperature (Research)*1 |

52°C at Std. Barometer Base Temperature depends on Barometric Pressure |

|

Intake Mixture Temperature *2 |

149°C±1°C |

|

Cylinder Jacket Coolant Temperature |

100°C±1.5°C |

|

Crankcase Oil Temperature |

57±8.5°C |

|

NOTE:*1 Intake air temperature for Research Method engines can be adjusted ±22°C from the base temperature specified for the prevailing barometric pressure if the rating unit is temperature tuned to rate a toluene standardization fuel blend. The temperature must then be maintained within ±1°C. See ASTM D2699 for details. |

|

|

NOTE:*2 Intake mixture temperature for Motor Method engines can be adjusted between 141°C-163°C if the rating unit is temperature tuned to rate a toluene standardization fuel blend. The temperature must then be maintained within ±1°C. See ASTM D2700 for details. |

|

|

Engine Information |

|

|

Compression Ratio (C.R.) |

4:1-18:1 |

|

Cylinder Bore(Diameter) |

82.55mm |

|

Stroke |

114.3mm |

|

Intake Valve Clearance |

0.2mm |

|

Exhaust Valve Clearance |

0.2mm |

|

Intake Valve Opens Timing |

10°±2.5° ATDC |

|

Intake Valve Closes Timing |

34° ABDC |

|

Exhaust Valve Opens Timing |

40° BBDC |

|

Exhaust Valve Closes Timing |

15°±2.5° ATDC |

|

Crankcase Oil Pressure |

172Kpa-207Kpa |

|

Function Information |

|

|

Compression Ratio Adjustment Method |

Motor-driven |

|

Compression Ratio Display Device |

Micrometer & Digital Counter |

|

Engine Speed Adjustment Method |

Motor-driven |

|

Carburetor |

Four Bowl (with cooling Function) |

|

Spark Timing Display |

Yes |

|

Crankcase Pressure Display |

Yes |

|

Crankcase Oil Heater |

Yes |

|

Crankcase Oil Temperature Display |

Yes |

|

Ice Tower Humidity Control Apparatus |

Yes |

|

Unit Protection Systems |

Yes (Optional) |

SINPAR persistently hold the service concept of “ Professional, Efficiency, Prompt” to supply excellent full-scale solution in all process of pre-sale, sale and after-sale service. SINPAR products are under one-year warranty and life maintenance.

Professional Service Team

SINPAR has a experienced professional Service Team to offer the World-wide Service of equipment installation, deb ing, maintenance, technical support and training.

Efficient Service Solution

We provide solution to any question and request from customers within 24 hours, and arrange special-assigned technical specialist to responsible for the communication and coordination service time with customer in whole course, which can save the customer time.

Global Service Network

SINPAR cooperates with global distributors to establish an extensive World-wide Service Network, which offers “Professional, Efficiency, Prompt” technical service and arranges technical specialist to do the routine visit and remind the maintenance time.

Timely Supply of Spare Parts

SINPAR has set up spare parts storehouses and timely supply system at world-wide service network, which could supply spare parts for customer timely and offer onsite service of replacement parts.

Training Center

In Shanghai a professional Training Center has been established to provide technical training courses for Octane engines at any time.

About SINPAR

Shanghai Sinpar Scientific Instrument Co.,Ltd- Professional Manufacturer of Octane Rating Unit, locates in Shanghai, is a high-tech company integrated with developing, manufacturing, sales and service for Combination (Research and Motor method) Octane Rating Unit (ASTM D2699 RON & ASTM D2700 MON).

Since SINPAR was established, it has been devoted to R&D of the high quality Octane Rating Unit in China and committed to offer the perfect solutions to customer.

SINPAR has set up a R&D Center which composed by experienced experts from National Petroleum Research Institute and professors from Petroleum Colleges. R&D Center integrates the advanced technology into the product innovation and offers the best technical training and after-sale service.

SINPAR FTC Octane Rating Unit which owning independent intellectual property rights in China, is in full compliance with ASTM D2699 and ASTM D2700. In the years since it was first introduced to market, FTC Octane engine has been updated regularly with features that enhance test accuracy and accurate fuel octane ratings. It is used not only in China with stable performance and good feedback, and also exported to Russia, South Asia, East Asia, Middle East, South America, Europe, North Africa and other countries and regions.

SINPAR sincerely wishes to cooperate with all the customers and distributors from all over the world and inaugurate a splendid future together.

SINPAR has always been devoted to Research & Development of the high quality Octane Rating Unit in China and committed to offer the perfect solutions to customer.

SINPAR R&D Center was established in Shanghai which composed by experienced experts from professional National Petroleum Research Institute and professors from Petroleum Colleges. R&D Center integrates the advanced technology into the product innovation and offers the best technical training and after-sale service.

SINPAR R&D Center has both knowledge and practical experience in the analysis and testing of petroleum products. Our experts and technical staffs use the most advanced testing equipment to ensure product quality, further ensures our products meet ASTM, ISO, and GB Standards.

Workflow of SINPAR R&D Center: