| Model: | EDI module RO |

|---|---|

| Brand: | Vliya |

| Origin: | Made In China |

| Category: | Industrial Supplies / Machinery / Filters |

| Label: | EDI module , RO plant , mixed bed system |

| Price: |

US $8000

/ set

|

| Min. Order: | 1 set |

| Last Online:08 Jan, 2016 |

Description of EDI module RO plant with mixed bed system water treatment plant

EDI Equipment

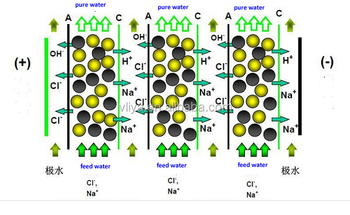

EDI (Electrodeionization) is a revolutionary water treatment technology; it is a membrane filtration and desalination technology that skillfully combined the electrodialysis technology and ion exchange technology together, which is high-tech, green and eco-friendly technology.

EDI equipment uses the RO outlet water as feed water. The resistivity of RO outlet water is normally 40-2μS/cm (25℃), and the resistivity of EDI outlet water can normally reach 18MΩ.cm (25℃). According to the application of deionization water and the setup of the system, EDI outlet water can meet the requirements for resistivity of 1-18.2MΩ.cm (25℃).

The advantages of EDI equipment are continual water production, no acid and alkali regeneration, unattended operation, etc. It is gradually replacing the mix bed as the fine treatment equipment. Due to its environmentally friendliness and ease of use, EDI equipment has been accepted by more and more people and widely used in pharmaceutical, electronic, electricity, and chemical industry. Its existence is a revolutionary progress of water treatment equipment, which marked the water treatment industry finally entered into green industry.

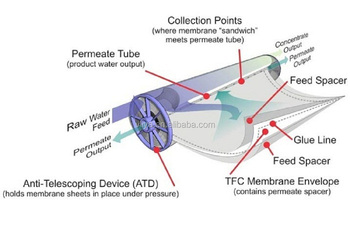

Reverse osmosis system is one of the most advanced technologies to process water inthe world. The processed water with high purification, good taste can get rid of 100% bacteria. The salt can be eliminated from the water by more than 98%, highly up to the national standard.The series of RO machines adopt imported PLC with Chinese touching screen automatically controled, with various protecting functions and high efficiency and safety grade.The machine could maintain operating automatically without the operator at present.It adopts 8040 series reverse osmosis menbrances from US company Hydeneng to ensure water quality .The parts are also whole imported to keep the machine to run steadily.It is widely used in foodstuff,pharmaceutical, chemical industry, electronic industry for terminal process. We have owned 1-20 Ton/h production capacity of design, development, and manufacturing. We also provide special specifications in advance.

Feature of EDI module RO plant with mixed bed system water treatment plant

EDI utilizes chemical-free regeneration method, which means a safer workplace because there is no need to store or handle hazardous acid and caustic. There are fewer regulation concerns due to the absence of these corrosive chemicals and there will be no waste neutralization or disposal issues.

EDI is a continuous process. The ion exchange resins are continuously being regenerated by the DC electric field. There is no excape of ions as happens in conventional ion exchange operations, therefore the quality of the water remains at a consistent high level of purity. The electric field also provides a bacteriostatic environment inside the EDI cell, inhibiting the growth of bacteria and other organisms.

EDI equipment has significantly lowered operating costs than conventional ion exchange processes. Only a relatively small amount of electric power is needed to complete the water purification. The lack of acid and caustic regeneration means less operator attention and lower labor costs. Capital costs can also be expected to be lower, especially because no chemical storage, pumping and neutralization equipment is required.

EDI equipment has a significantly smaller footprint than conventional ion exchange equipment. This means that less plant space will be required to provide the same quantity of water.