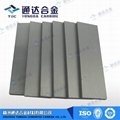

Tungsten carbide Strip is widely known as one kind of carbide cutting tools. Tungsten carbide strip is available for different grinding geometric parameters and suitable for both cutting materials and nonmetal materials, also it can be applied to conventional, carbide inserts, semi-automatic lathe, automatic lathe and planning machine to work grooves and operate cutting, etc.

Tungsten carbide strip is extensively processed into reamers, drill bits, milling cutters, end mills, face mills, shell mills, burs, boring cutter, countersink cutters, gun drills, thread shavers, gravers, solid engraving tools, solid burrs and so on.

Tungsten Carbide Strip Features

Tungsten carbide strip is widely used in industry because of its extraordinary properties:

1. Strict tolerance extent control

2. Excellent wear resistance & high toughness

3. Very good thermal & chemical stability

4. Anti-deformation & deflection

Because of its wear resistance and hardness (9.8 Moe's scale), tungsten carbide strip is ideally suited for wear parts, other machine parts and dies which are subject to severe service conditions, such as high temperatures, corrosion and abrasion. In recent years, tungsten carbide has emerged as a superior alternative to steel in many industrial applications.

Because of its longer wear qualities, tungsten carbide strip translates into significant cost savings for OEMs, including: smaller parts inventories, less downtime to replace worn components, greater productivity.

Tungsten Carbide Strip Applications

Tungsten carbide strip further processed into cutters is widely used in ceramics, printing machinery, forestry, rubber, plastics, light textile industry, cigarette machinery, packaging materials, cable, shipbuilding, metallurgical machinery and electronics, leather industries, such as circular carbide blade, plastic granulator roller blade, circular blade for asbestos gas cutting machine slitting blades, sheet metal processing blades, etc. standards and non-standard mechanical blade.

Tungsten carbide Strip is used mainly in cutting metals, wood, paper fields, therefore strip requires high-quality to acquire a longer life circle and cutting speed.

Tungsten carbide strip is suitable for the processing of the chilled cast iron, alloy steel. Tungsten carbide strip is also used for precise processing of precise cast iron and the production of wear resistant parts.

With good bending strength and wear resistance, not only is tungsten carbide strip applied in slow rough turning ,heat resisting aloys milling and the semi-finishing of titanium alloy, stainless steel and low-alloy steel, but it is also suitable for the processing of glass steel and the production of PCB micro-drilling etc.

Advantage:

1.We are a professional tungsten carbide manufacturer in Zhuzhou City over 10 years and have a few senior engineers who specializes in tungsten carbide field for many decades;

2.Recommended grade :YG6(K10) YG6X YG8(K20) YG15(K30), we can research and developmore suitable formula according to use condition and processing characteristics for client.

3.For your non-standard parts,we have strong ability to make mold by ourselves,and produce them per your requirements.

4.We have strict quality control and assurance system to guarantee the consistent quality.