| Model: | DY-1 |

|---|---|

| Brand: | dongyue |

| Origin: | Made In China |

| Category: | Industrial Supplies / Construction Machine |

| Label: | pole mould , concrete pole mould , spun pole mould |

| Price: |

-

|

| Min. Order: | 1 set |

| Last Online:21 May, 2024 |

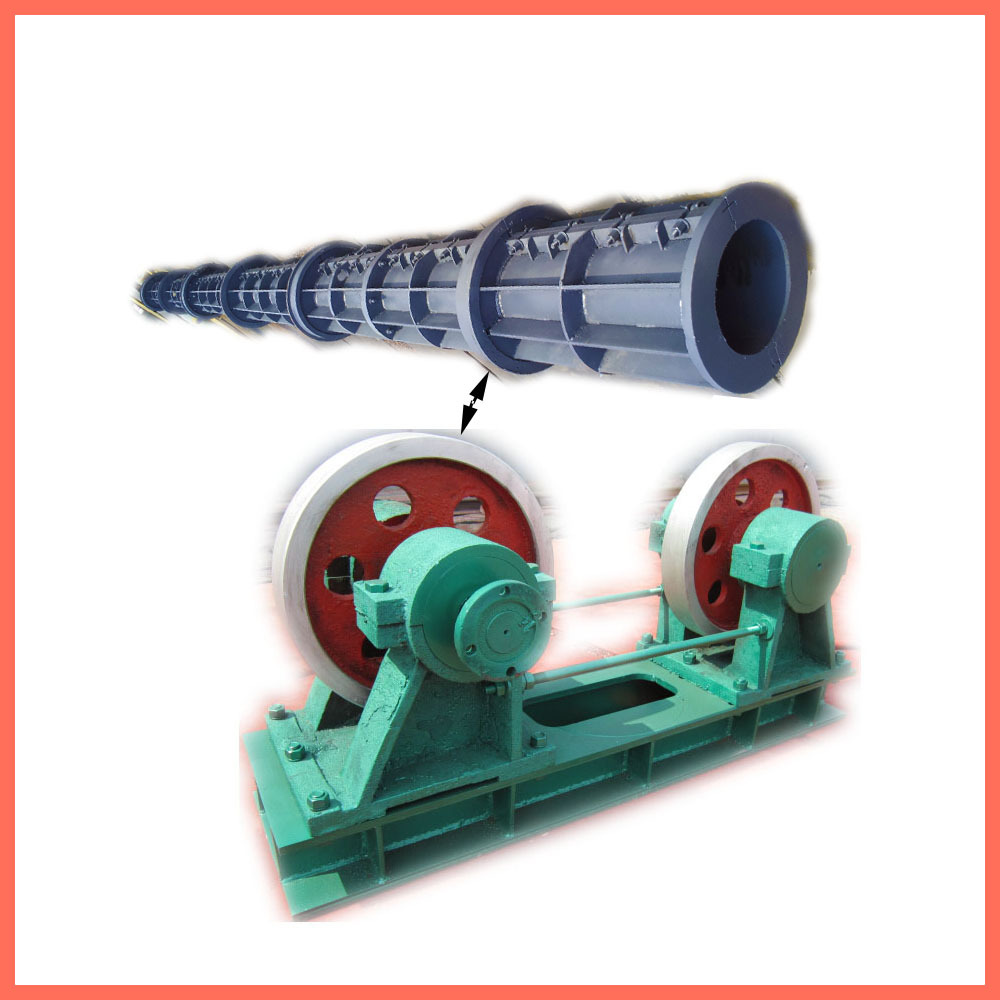

Prestressed spun concrete pole mould with custom services

Reinforced pole steel machines

Product Description

Reinforced cement pole machines is used for concrete electrical pole manufacutring. Its mainly manufacture technology is longitudinal tension by steel wires. During rotation of mould, it can squeeze out the excess water contained in concrete under centrifugal force. Thus, it can greatly improve the concrete density and strength.

Specifications

Reinforced cement pole machines

For 10m,11m,12m,13m,14m,15m ,16m,18m and customised need

Hot Sell High Quality Reinforced cement pole machine

Overvie

Reinforced cement pole machine is a kind of mould equipment, which used for making a variety of different diameter and length of reinforced and pre-stressed concrete poles and other cement products.

Reinforced cement pole machine is operated by remote-controlled continuously variable motor. It runs smoothly and has a variable-speed range. So the production of concrete pipes and piles are good at quality.

The base of the machine is welded in box-type structure, sturdiness and durability. The bearings are sealed and reliable, long life. Random electric control equipment is complete and easy to use.

Working Principle

1. Adding the slurry into the mould, it is driven quickly and rotated in the same speed of the machine. Each component is separated and released under the centrifugal force. Usually the higher the slurry rotate speed, the better the slurry separating effect.

2. Centrifugal sedimentation is the use of different density of each component in the slurry, which is rotated under the centrifugal force. To realize the liquid - solid (or liquid - liquid) separation.

3. The speed of separation is slow when the viscosity of slurry is high.

4. It is good for centrifugal sedimentation when the slurry density is different in each component.

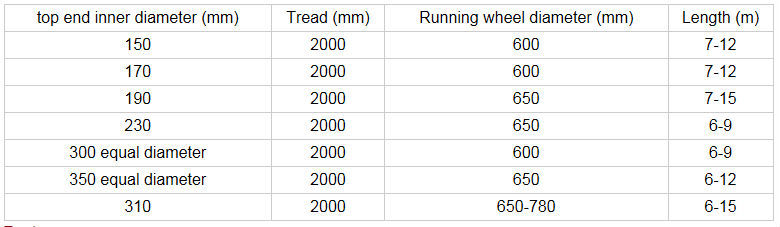

Technical Parameter(Order can be customized)

Features:

1. Saving a great deal of steel, about 30~70% (employing cold drawn steel wire can save 30%~60%; employing high stress steel wire can save 40%~69%).

2. Crack resistance can increase about 3~5 times.

3. Rigidity increases 1~3 times.

4. Reducing the cost (using cold drawn steel wire can reduce 25%~40%; using high stress steel wire can reduce 12%~21%).

5. Good durability, can delay the existence and expansion of cracks.

6. Protect the environment on which human beings depend on for existence, and reduce the deforestation.

| Payment Terms: | T/T,L/C |

|---|---|