| Model: | ZZS1120 |

|---|---|

| Brand: | Guotai |

| Origin: | Made In China |

| Category: | Industrial Supplies / Other Industrial Supplies |

| Label: | optical system , optical coating , vacuum coating |

| Price: |

¥300000

/ pc

|

| Min. Order: | 1 pc |

| Last Online:07 May, 2016 |

Optical Coating Machine Vacuum Equipment For Coating Telescope Mirror

Working principle:ZZS series vacuum coating machine adopt electron gun bombardment materials evaporation technology for work-piece coating ,in order to change workpiece surface performance and get required coating products.

Introduction:

This equipment is designed for precision optical thin film coating production,system unit and overall structure good to meet the requirements of the optical thin film production process,suitable for coating anti-reflection film, bandpass membrane,cut off film and other coating film system.It is equipped with high-precision film thickness control system,excellent performance of electron gun,high degree automation of coating control system, etc. It's the ideal of high precision optical thin film plating equipment.

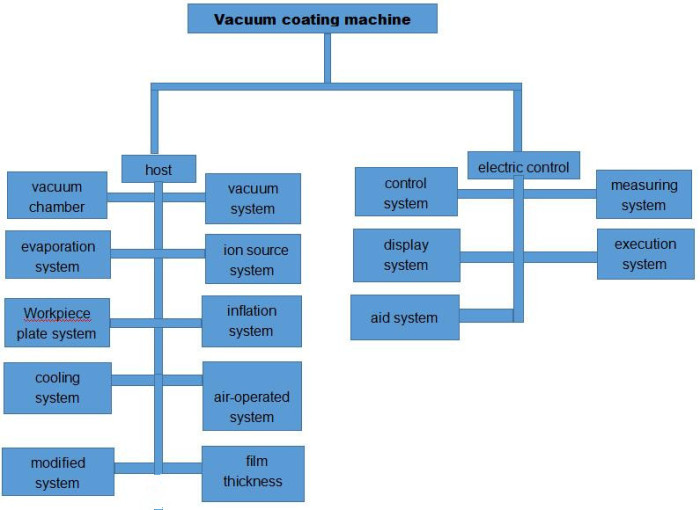

Equipment structure:

Features:

Fully integrated in the machine control platform.

Fully automated coating process and control.

High speed coating process.

Stable productivity and uniformity

Easy job and process set-up and maintenance.

User-friendly control software.

Specification

|

Model |

ZZS1120 Optical Coating Machine |

|

Dimension |

Φ1120mm×H1300mm |

|

Substrate dome Size |

Φ1050mm |

|

Vacuum chamber Structure |

Cabinet type single door , 304 stainless steel material |

|

Ultimate vacuum |

3×10-4Pa |

|

Restore vacuum |

4×10-3Pa,≤12 minutes |

|

Vacuum pumping system |

Mechanical pump+ roots pump +diffusion pump |

|

Substrate dome structure |

Three or four fan,ball,custom made |

|

Substrate dome rotation speed |

3~30 r.p.m |

|

Baking structure |

Up barrel heating, down radiation heating |

|

Heating material |

Tubular heaters, iodine tungsten lamp |

|

Control mode |

Touch Screen,PLC,Manual and Automatic |

|

Temperature |

350℃ |

|

Temperature uniformity |

350℃ ± 10 ℃ |

|

Evaporation source |

Resistance evaporation source, electron beam evaporation source. |

|

Working environment requirements

|

1. Environment temperature:10~35℃ 2 .Relative humidity: no more than 80% |

|

Equipment power requirements |

Water source: industrial water softening or circulation water. Water pressure: 0.15 ~ 0.25 Mpa, Water inflow temperature:≤25℃; Gas source:pressure 0.6MPa Power supply: three-phase, 220 V / 380 V, 50 HZ |

Application:

Optical Coating Machine are widely used for coating Anti-Reflection Coatings,Beamsplitter Coatings,Dielectric Mirrors,Fibre Optic Coatings,Front Surface Mirror,Large Area Dielectric Beamsplitters ,Large Front Surface Mirrors ,Metal Coatings,Neutral Density Filters,RFI shielding, Anti-static and Heated Window Coatings,Unbreakable Plastic Mirrors,UV Mirror Coatings,Telescope Mirror Coating / Re-coating,Cleaning Front surface Mirrors.

Advantages:

1.Rich experience in Optical coating industry, we design and manufacture optical coating machine to meet your process requirements.

2.Undertaking a variety of optical coating services.

3.About 2 months production time.

4.One year warranty, life-long maintenance

5.Wearing spare parts for free.

6.Provide door-to-door installation services,

7.Wooden package

8.T/T,Western Union payment available

9.Convenient transportation and timely delivery.

We are factory ,with rich experience in design and manufacture optical coating machine,also,we can undertake optical coating service.Show me your products,Chengdu Guotai will give you a solution to meet your coating requirements.

Workshop show

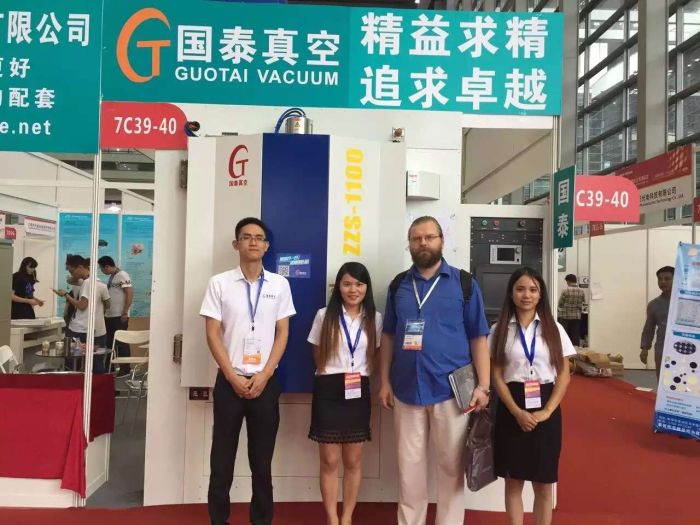

Our team

Customer visit

Exhibition

Certification

Package show

Note:

1.We have more optical vacuum coating machine models,such as ZZS500,ZZS630,ZZS800,ZZS900,ZZS1100,ZZS1300,ZZS1600,ZZS1800,ZZS2000,ZZS2350.

2.Equipment final size and configuration customized production according to your requirements.

What we can do more for you :

1.One year guarantee period ,life-long maintenance.During warranty period free replacement parts.

2.The whole electric control manufactured by us, including vacuum gauge and pressure control instrument,etc.Once there are problems,we will be free to provide them to you to replace ,make sure decrease your lose during equipment downtime.

3.Free training for operation and maintenance personnel,provide detailed equipment maintenance materials,include consumables parts number and contact way,to make sure customers can independently replace vacuumpump,regular system maintenance,when necessary.

4.If fault occurs during equipment use process,we will respond within 24 hours,If due to manufacturing reasons,we will bear responsibility.

5.We will keep long-term tracking ,when upgrading products we will provide cost price replacement , to make equipment achieve better performance,to realize our compromise of equipment further improve and perfect .

6.We can make relative adjustment according to your special requirements .

Please feel free to contact me :

Contact person:Alice

Skype / Wechat:alice2013681

WhatsApp:+8613408484278

Phone: +8628-82666357, +8628-82666563

Fax:+8628-82666193

Mobile Number:+8613408484278

Email:optical.coatingdevice@yahoo.com

Facebook:852569632@qq.com

Follow me on twitter: https://twitter.com/opticalcoating1

Web:http://www.gtvacuum.com / www.cdguotai.com

| Payment Terms: | T/T |

|---|---|