| Model: | S212-50 |

|---|---|

| Brand: | Lanphan |

| Origin: | Made In China |

| Category: | Industrial Supplies / Chemical Machinery |

| Label: | Glass Reactor , Glass Reactors , S212-50 |

| Price: |

US $600

/ pc

|

| Min. Order: | 1 pc |

| Last Online:20 Jul, 2016 |

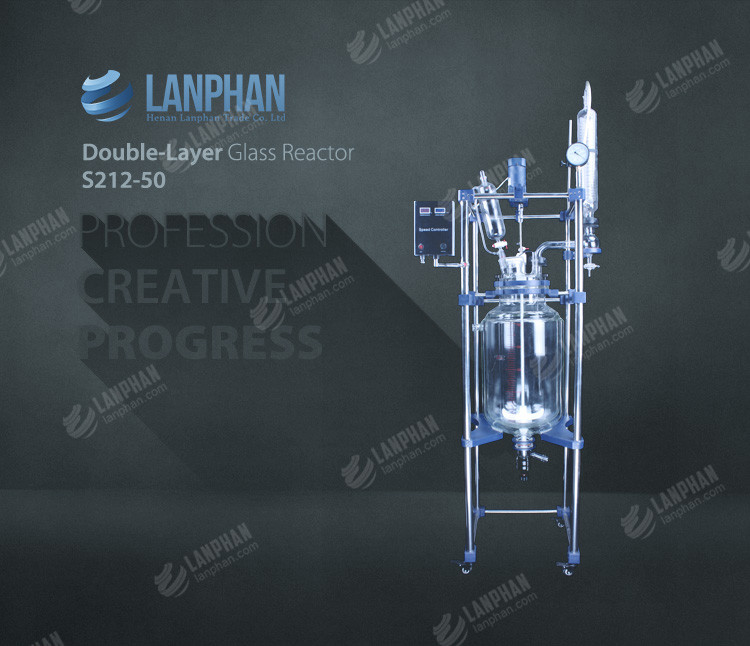

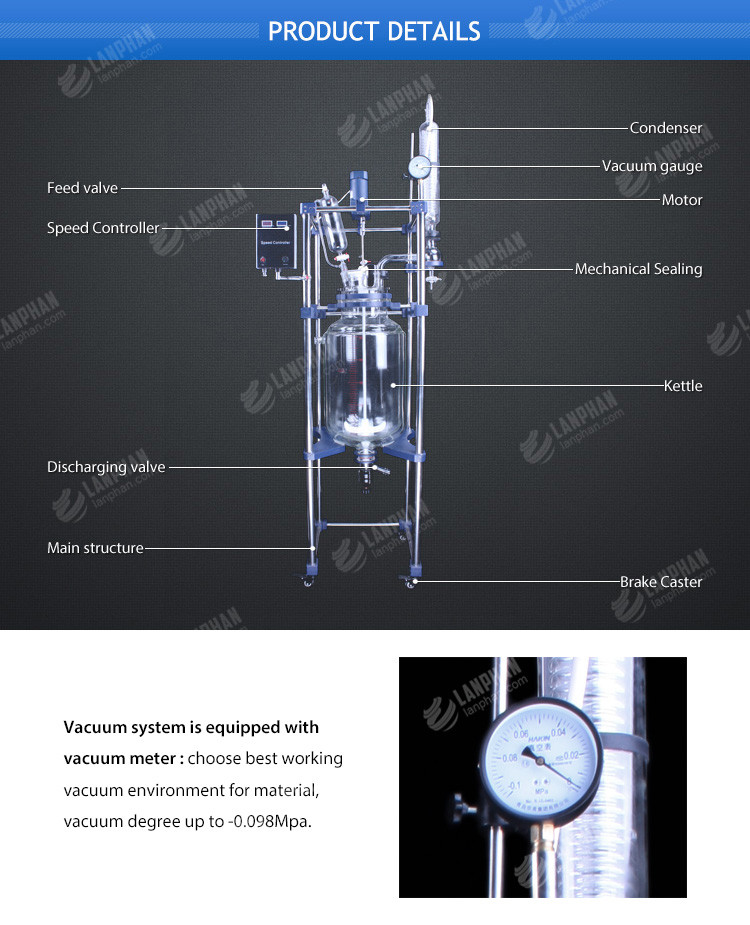

Lanphan S212-50 double-layer glass reactor’s reaction flask volume is 50L, interlayer volume is 12L, stirring diameter of axle is 12mm, power of stirring is 120W. S212-50 double-layer glass reactor is an audacious product who has combined advantages of domestic and foreign like products, it adopts double-layer glass design, put reaction solvent in internal layer to do stirring reaction, connect different cold and heat sources(refrigerating fluid, hot water or hot oil) to interlayer to do cyclic heating or cooling reaction. Under set constant temperature condition, you can conduct stirring reaction under normal or negative pressure in airtight glass reactor, as well as conducting backflow and distillation of reaction solution. S212-50 double-layer glass reactor is an ideal pilot test and production equipment for modern fine chemical engineering, biological pharmacy and new material synthesis. This glass reactor series mainly contains following parts: double-layer glass reaction kettle, a set of component cover of glass reactor, condenser, constant voltage funnel, frequency conversion controller, rotate stirring and sealing system, stainless steel frame system, etc.

Product features of S212-50 double-layer glass reactor:

1.Constant rotate speed, no electric brush, no spark, safe and stable, enable continuous working.

2.Full set of glass part is produced by G3.3 borosilicate glass, owns excellent chemical and physical properties.

3.When glass interlayer connecting to hot oil and been circulated, it can do heating reaction, connecting to refrigerating fluid can do low temperature reaction.

4.Enable reaction under normal temperature, that is connecting to tap water can take away the reaction heat quickly.

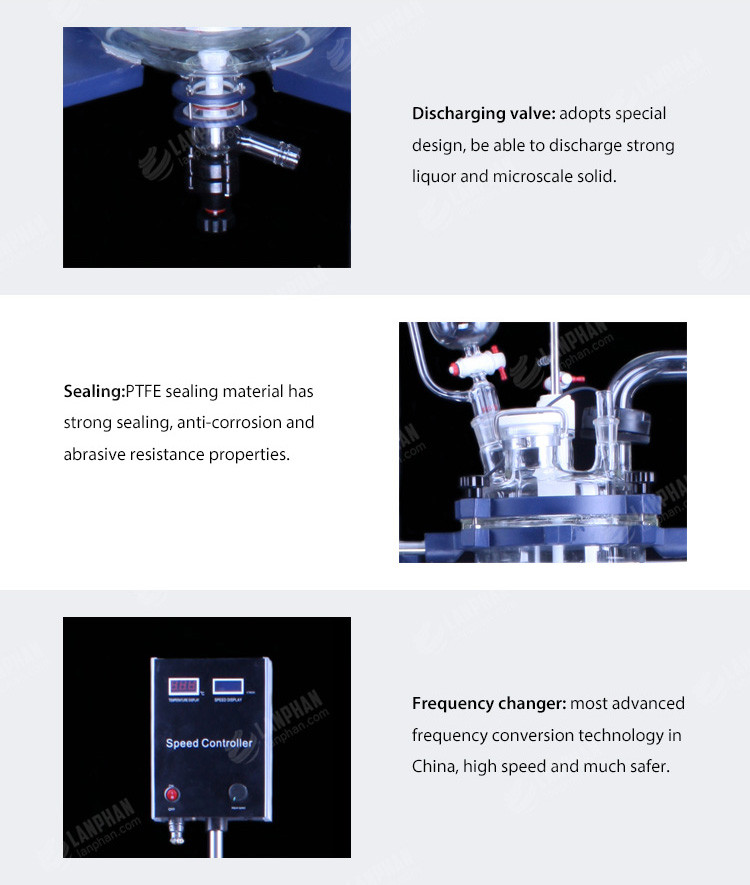

5.Discharge outlet has flange mouth and PTFE valve, there has no dead angle in vessel, detachable and convenient for solid material to discharge.

6.Main body is made from stainless steel, which is beautiful and anti-corrosion.

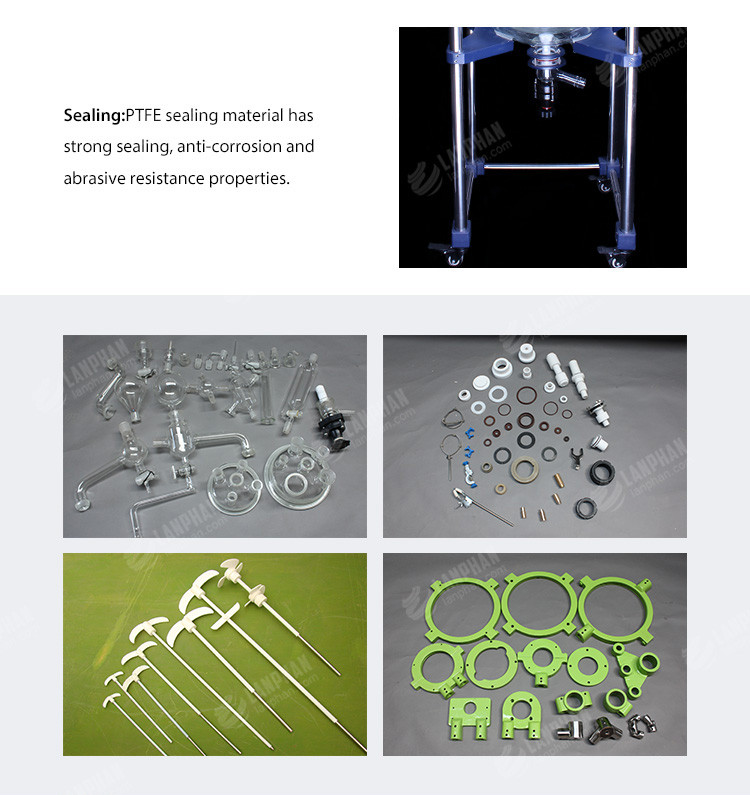

7.Sealed by PTFE component, be able to maintain higher vacuum degree.

8.Be able to work under normal and negative pressure, negative pressure up to -0.09MPa.

9.Alternating current dynamo conducts frequency control stirring, reliable operation, large moment of force and no spark.

10.The inner core of stirring rod is made from 321 stainless steel, strengthened anti-corrosion property, military technology makes workmanship more exquisite, operation with high proficiency.

Packing List of Lanphan S212-50 Double-Layer Glass Reactor

|

Serial Number |

Accessory Name |

Quantity |

Explanation |

| 1 |

Double-layer reactor |

1 pc |

Effective volume 50L |

| 2 |

Stirring electrical machine |

1 pc |

Rotate speed starting -1350 rotate(adjustable) |

| 3 |

Speed controller |

1 pc |

With digital display function(stepless speed regulation) |

| 4 |

5 mouth reactor cover |

1 pc |

Matching use with reactor |

| 5 |

Reactor shelf |

1 set |

To support rector |

| 6 |

Condenser |

1 pc |

Distill and condensate |

| 7 |

PTFE discharging device |

1 pc |

Discharging(detachable) |

| 8 |

Thermometer well |

1 pc |

To put thermometer |

| 9 |

Constant Voltage funnel |

1 pc |

Charging in vacuum condition |

| 10 |

PTFE stirring bar |

1 set |

Inner diameter is made from stainless steel material, covering is made from TEFLON anti-corrosion material |

| 11 |

Distillation condensate elbow |

1 pc |

Connect to reactor cover and condenser, used to separate and concentrate |

| 12 |

Vacuum chock plug |

2 pcs |

Used to seal |

| 13 |

Vacuum tapping |

1 pc |

Used to extract air in reactor so as to obtain vacuum |

| 14 |

Circulating oil bath |

1 pc |

Microcomputer control, providing high temperature heat source(with circulatory system; high temperature 300℃) |

Technical Parameter of Lanphan S212-50 Double-Layer Glass Reactor

|

Basic Parameter |

Type |

S212-50L |

|

Glass material |

GG-17 |

|

|

Frame material |

Stainless Steel |

|

|

Pipe fitting material |

304 Stainless Steel |

|

|

Move method |

Universal castors with braking |

|

|

Reaction flask volume |

50L |

|

|

Interlayer volume |

12L |

|

|

Flange type oil in and out circulation port |

Enter from low port, come out from high port |

|

|

Number of reactor bottle |

6 | |

|

Discharge outlet liftoff height |

450mm |

|

|

Reactor reaction temperature |

-80-250 degree |

|

|

Vacuum degree |

0.098Mpa |

|

|

Stirring speed |

0-450rpm |

|

|

Stirring diameter of axis |

12mm |

|

|

Stirring power |

120W1/3 |

|

|

Voltage/Frequency(V/Hz) |

220V/50Hz |

|

|

Boundary dimension(mm*mm*mm) |

760*560*2450 |

|

|

Package Dimension(mm*mm*mm) |

1720*680*850 0.99m³ |

|

|

Package weight(KG) |

92 | |

|

Functional Configurations |

Speed adjustment mode |

Electric stepless speed regulation |

|

Electrical machine configuration |

Low speed reinforcement electrical machine, speed ratio 3:1 |

|

|

Rotate speed display mode |

Liquid crystal digital display |

|

|

Temperature display mode |

PT100 sensor digital display |

|

|

Sealing mode |

PTFE sealing, ¢50 flange stirring mouth |

|

|

Condenser |

Vertical high efficiency double backflow condenser pipe 120*640mm, 40# standard mouth |

|

|

Backflow (distillation) device |

Backflow elbow is equipped with discharge switch, 50# ball milling mouth |

|

|

Dropwise adding device |

2K constant voltage funnel, 40# standard mouth |

|

|

Depression device |

34# standard mouth reducing valve |

|

|

Temperature testing tube |

24# standard mouth |

|

|

Solid charging |

¢80 flange mouth with PTFE cover |

|

|

Discharging method |

Inclined glass discharging valve, ¢80 flange mouth |

|

|

Vacuum display mode |

Vacuum meter |

|

|

Stirring connecting method |

Universal joint connecting |

|

|

Stirring bar |

Anchor type stainless steel bar, covered with PTFE |

|

|

Optional Configurations |

Main body support |

Tray type |

|

Collecting device |

Collection bottle |

|

|

Anti-Explosion |

Anti-explosive frequency changer, anti-explosive electric machine EX180W 0-1400 rotate |

|

|

Frame part |

Spraying plastics pr PTFE |

|

|

Heat insulation device |

Cotton insulation |

|

|

Sealing part |

Ceramic bearing, mechanical sealing |

|

|

Condenser |

Horizontal type condenser can reduce overall height |

|

|

Reactor cover |

Custom-made PTFE reactor cover |

|

| Our company's laboratory glass and laboratory instruments are independent research and development, available for custom-made according to client requirements. | ||

Lanphan S212-50 double-layer glass reactor is an ideal equipment for modern chemistry sample, petrochemical engineering, pilot experiment, biological pharmacy and new material synthetic.

S212-50 double-layer glass reactor can conduct following experiments:

1.Vacuum stirring reaction;

2.High and low temperature reaction;

3.Constant speed operation blending reaction;

4.Distillation, backflow, concentration;

5.Negative pressure operation, skimming function;

6.Rectifying by assembling rectifying column;

7.Phytoextraction has better process effect in concentration;

8.Stirring separating, equipping with skimming device, effect is obviously;

9.Conduct reaction and production of ultrafine powder, sanitation class made medicine is extremely clean;

10.Be able to replace rotary evaporator to do high purified material concentration, equipped ultrasonic stirring reduced reaction time multiple;

11.No matter separate or compound, convenient to charge, easy to handle.

Pre-sale Service

1. According to product’s using condition, technicians will offer rationalization proposals to assist clients to select proper types;

2. Provide detailed product performance specification;

3. Provide professional quoted price;

4. Provide 24-hour technical consulting reply.

In-sale Service

1. Begin to supervise from raw material, its qualified rate can reach to 100%;

2. Whole manufacturing process are in strict accordance with promised procedure requirements, product qualified rate can reach to 100%;

3. Provide product’s inspection record of key junctures to customers;

4. Provide production schedule photos to customers at regular intervals;

5. Package and transport products strictly accordance with export standard;

After-sale Service

1. Under the premise of correct installation, normal maintenance and using, we guarantee one-year warranty period;

2. When warranty period has expired, our sold products enjoys lifetime guarantee repair, we only charge cost price for changing product’s standard component and sealing component;

3. During installation and adjustment period, our after-sale service staff will communicate with customers frequently to know product’s running state in time. Assist customers to install and adjust products until customers are satisfied;

4. If product has malfunction during operation period, we’ll offer you satisfied answer in time. We’ll reply you within 1 hour and provide solution or send staff to spot within 24 hours after receiving maintenance notification.

5. Lifelong free technical support. Conduct satisfaction survey and inquiry equipment running condition to clients by telephone or e-mail semiannually from the first day of equipment running, put on records of acquired information.

1.What’s the difference between single-layer and double-layer glass reactor?

Answer: Single-layer glass reactor can directly heating or cooling, it is similar to water or oil bath, inferior in temperature control aspect; while double-layer glass reactor has interlayer between two layers, we can inject water or oil through temperature control equipment and form circulating system, in this way, no matter cooling or heating, its temperature control property is better.

2.How to decide which glass reactor I should buy? Single-layer or double-layer?

Answer: According to first question, please depend on specific heating or cooling requirements.

3. What is the glass texture?

Answer: Full set of glass part is produced by G3.3 borosilicate glass, owns excellent chemical and physical properties.

4. How about the applicable environment?

Answer: Can be used in a wide temperature range between -80℃ and 200℃.

5. Is it easy to clean the reaction bottle?

Answer: Big cleaning hole is convenient to clean.

6. What kind of payment term do you accept?

Answer: Normally we accept TT, Paypal, Western Union, Alibaba Escrow, and L/C. The exactly term with be discussed during the deal.

7. How will you delivery these goods?

Answer: It will be decided according to your quantity. Normally we will choose International Express, Air and sea.

8. How to package the products?

Answer: We package products in dedicated carton, you can order Non Fumigation wooden case if has special requirements.

1.We can assemble glass reactor production line according to client requirements.

2.Our company’s lab instruments are independently research and developed, we can custom-made non-standard instruments according to client requirements.

3.Controller uses microcomputer control, enables higher accuracy and lower fluctuation.

4.Lanphan S212-50 double-layer glass reactor absorbed advantages of international and domestic like products, innovate boldly and easy to use(convenient for only one person to move, operate, clean and dismantle).

5.Leading technology in China of put reaction mass in interlayer, conduct stirring reaction in normal or negative pressure, it’s a new-type frequency control double-layer glass reactor on basis of client’s actual needs.