Product Description

Box-type furnace and tube-type furnace are called muffle, they are a kind of universal heating device which different in shapes. SX2 series box-type furnace is a self-researched product by our company, it’s a smart, high efficient, energy saving, environmental protection precision high temperature electric furnace. SX2 box-type furnace owns advanced structure, elegant and beauty in appearance, shell is made from excellent cold-roll steel sheets, been processed by advanced numerically controlled machine tool and import epoxy powder electrostatic spray technology, anti high temperature, anti corrosion and maintain no color fading for a long time.

SX2 series high temperature box-type furnace use high quality resistance wire, silicon carbide rod or molybdenum rod(subject to specific high temperature requirements of clients) as heating element, adopts double-layer shell structure and smart temperature control system, hearth is made from aluminium oxide multicrystal fiber material, high thermal shock resistance, strong quick heating and cooling property, excellent corrosion resistance property, non collapse, non crystal, no pollution, long service life. Double-layer furnace shell is equipped with air cooling system, enable rapid temperature rising and falling, use soft start constant-current control to lengthen heating device’s life, it has advantages of high temperature control accuracy, thermal field balanced, operate easily, high speed and low energy consumption.

Product features of Lanphan SX2 box-type furnace:

- Lanphan box-type furnace has a widely application range, can be used for gravimetric analysis, ash content measurement of organic matter and coal.

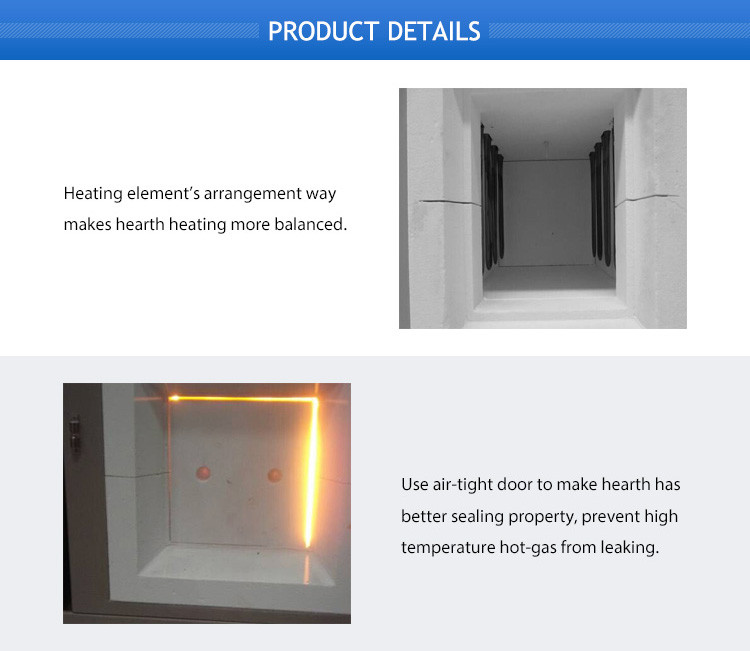

- Heating device is built in both sides of hearth inwall, which can quicken temperature rising and make material uniformly heated.

- Box-type furnace’s heating element is made from special fireproofing material, and it totally hides in inwall, avoid corrosive gas and steam, thus lengthen service life.

- Box-type furnace is separate from control part, in this way, electronic temperature controller can accurately control temperature even under long time running.

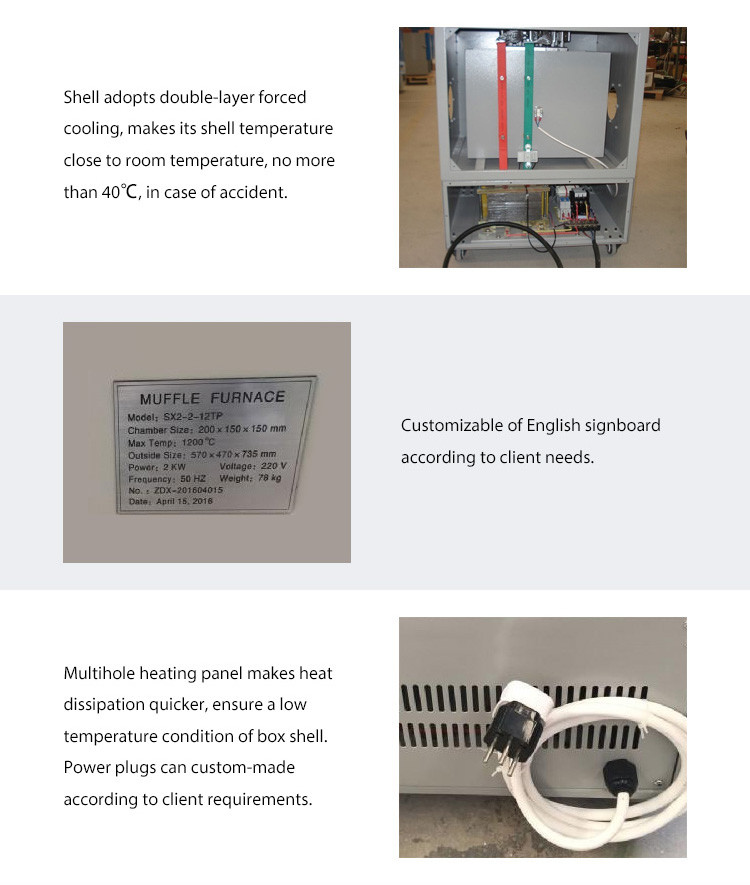

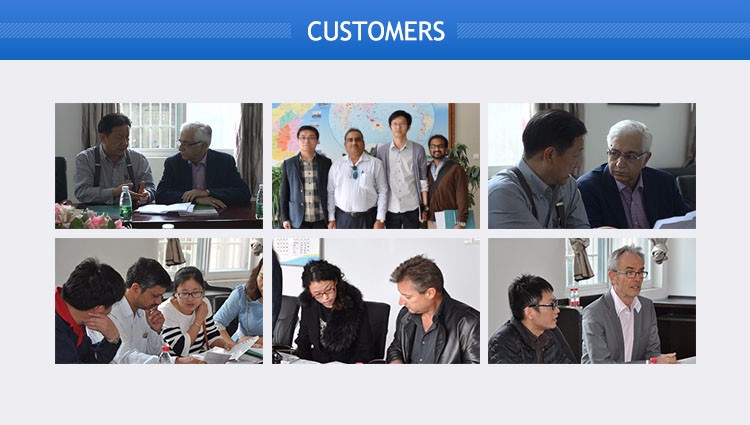

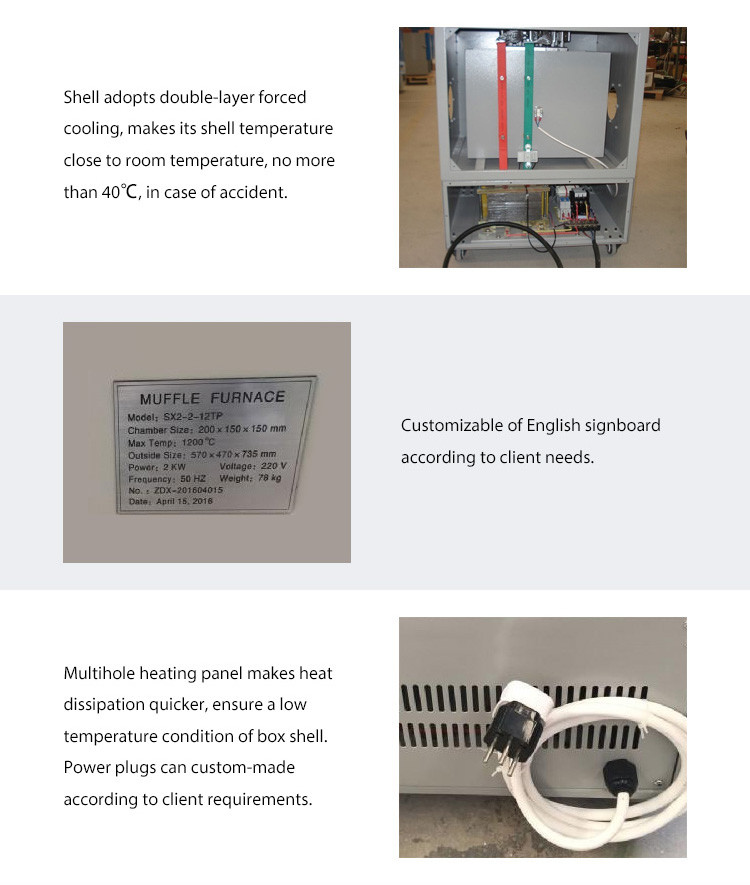

- Box-type furnace’s shell has double layers, its bottom is equipped with a refrigeration fan, the air circulating can keep low temperature of the surface, you have no worry for scalding.

- Digital setting and display panel points to accurate temperature.

- Temperature control range from 30℃ to 50℃, accuracy is ±1℃.

- Heating rate is 0-40℃/min(advise =<20℃).

- Hearth is made from aluminum oxide ceramics.

| Type |

Max

Temperature |

Heating

ELement |

Thermocouple

& Measuring

Range |

Hearth size |

Power |

Input

Power

Voltage |

Product Size |

| SX2-1-12TP |

1200℃ |

Resistance

Wire |

K type |

100*100*100mm |

1kW |

220V |

250*380*240 |

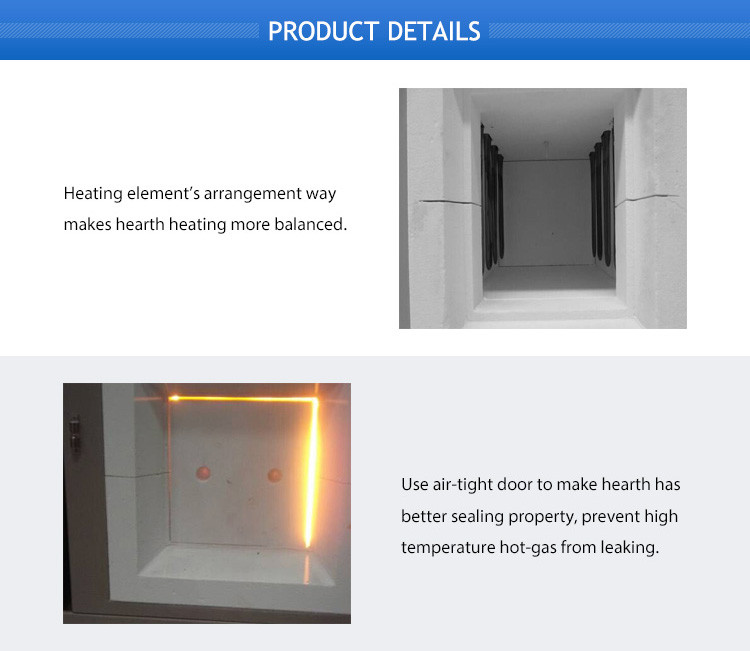

| SX2-2-12TP |

1200℃ |

200*150*150mm |

2kW |

220V |

470*735*570 |

| SX2-6-12TP |

1200℃ |

300*200*200mm |

6kW |

220V |

520*825*662 |

| SX2-9-12TP |

1200℃ |

400*300*300m |

9kW |

380V |

620*975*762 |

| SX2-2-14TP |

1400℃ |

Silicon

Carbide

Rod |

S type |

100*100*100mm |

2kW |

220V |

320*510*400 |

| SX2-4-14TP |

1400℃ |

200*150*150mm |

4kW |

220V |

470*735*570 |

| SX2-9-14TP |

1400℃ |

300*200*200mm |

9kW |

380V |

520*825*662 |

| SX2-16-14TP |

1400℃ |

400*300*300mm |

16kW |

380V |

620*975*762 |

| SX2-2-17TP |

1700℃ |

Molybden

um Rod |

B type |

100*100*100mm |

2kW |

220V |

320*510*400 |

| SX2-4-17TP |

1700℃ |

200*150*150mm |

4kW |

220V |

470*735*570 |

| SX2-9-17TP |

1700℃ |

300*200*200mm |

9kW |

380V |

520*825*662 |

| SX2-16-17TP |

1700℃ |

400*300*300mm |

16kW |

380V |

620*975*762 |

When putting metal and other mineral into high temperature furnace, please place them on high temperature resistance porcelain crucible or porcelain dish, or pas fire-resistant clay or asbestos sheet, in case of adhesion with hearth.

- high temperature protection gloves

- crucible tongs

- high clean steel crucible

- high temperature base plate

- Hot working, cement, construction material industry: small size workpiece hot working or treatment.

- Medicine industry: used for drug testing, medicine sample pre treatment.

- Analytical chemistry industry: sample treatment of water quality analysis, environment analysis domain, as well as petroleum analysis.

- Coal analysis: used for moisture measuring, ash specification, volatile matter, ash fusion point, ash component analysis, element analysis, as well as ashing furnace.

Our Service

Pre-Sales Service

- Provide professional quoted price.

- Provide product sample book, company introduction and credit certificate.

- Invite client to our company to inspect product design, production technology, workshop, product testing machine and quality management system.

- We can appoint experienced technical staff to offer you free design and model selecting according to actual using situation and specification.

- Provide professional quoted price.

In-Sales Service

- After place an order, order supervisor will follow up production procedure timely to ensure in time goods delivery.

- During production process, clients can send technicist to our company to inspect production process, we will provide inspection standard and results of our products.

After-Sales Service

- Except for man-made or abnormal operation to cause damage, we carry out “three guarantees”, warranty period for main engine is 3 years, please call us and tell fault reason if equipment is damaged.

- Free quality warranty period of the furnace is 3 years(except for heating element and easily smash and consumable matters), temperature controller, thermocouple, regulator, transformer and voltage regulator’s guarantee period is 3 years, if heating element has natural damage within 3 months, we will change it for free.

- Furnace box temperature is more than 1000℃, will it hurt people?

Furnace shell adopts double-layer forced cooling, makes its shell temperature close to room temperature, no more than 40℃, in case of accident.

- How long will it take to heat the furnace to 1300℃?

Our max temperature rising rate is 40℃/min, it will cost 32.5 minutes to rise to 1300℃. We advice you to use heating rate of 20℃/min to lengthen equipment service life.

- Usually I only need 900℃ to conduct my experiment, can I have a furnace with max temperature of 1000℃?

Yes, we can custom-made the furnace according to your need.

- The setting temperature on display refers to hearth temperature or sample surface temperature?

When thermocouple is collecting temperature data, probe directly touch the tested material, not influenced by medium, so it is the actual temperature of sample surface.

- Can I use our country’s plug?

Yes, we can provide following standard plugs in different countries.

- Comparing to fuel furnace, Lanphan box-type furnace is accessible to achieve high temperature;

- Heating from interior of material;

- Electric furnace has no heat loss due to exhaust gas comparing to fuel furnace, owns higher thermal efficiency;

- Microcomputer PID controller, high temperature control accuracy, procedure temperature control id reliable and safe;

- Heating rate is free to adjust, high temperature rising rate and low energy consumption;

- Excellent operating performance, no environment pollution;

- Shell is made from import epoxy powder static electricity plastic spraying process, anti high temperature, anti oxidation, anti acid-base, hard to color fading;

- Lanphan box-type furnace use integrating circuit, modular control, double-circuit protected(bias-temperature protection, superhigh temperature protection, over current protection, over pressure protection functions), working stably and safer.

Product Image

Img 1

Img 2

Img 3

Img 4

Img 5

Send Inquiry to this Member

Related Products of this Company

This member assumes full responsibility for the content of this listing. DIYTrade accepts no responsibility whatsoever in respect of such content.

To report fraudulent or illegal content, please

click here.

China Suppliers Quick Searching:

,