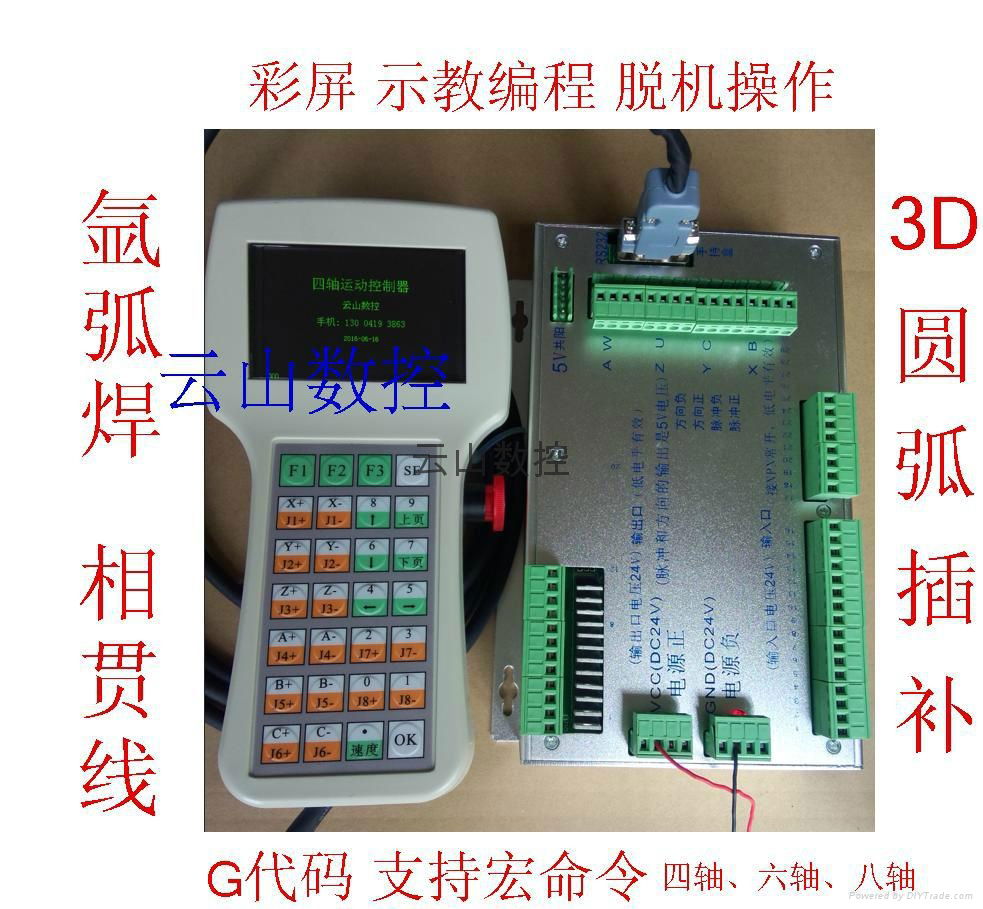

Handle controller for argon arc welding equipment

Product Description

Especially suitable for argon arc welding.

Welding intersecting line.

Before applying to other fields, please contact the customer service by telephone to confirm whether it is appropriate to use and to shoot again.

There is no pause between the 1 features, and the processing is very coherent and fluent;

Features 2, a chip up to 30 axis linkage;

Characteristic 3 use the low cost monolithic integrated circuit system to complete the space six joint manipulator's control system;

Other companies at home and abroad are using industrial computer to do, and their bottom of the algorithm I did not refine.

Characteristic 4 is applied to the welding machine of four stepping drives, the welding effect and the use are simple and convenient,

Are better than other domestic companies produce prices within 6000 yuan of the same type of products.

Characteristic 5 can easily teach and weld intersecting lines in space.

Characteristic 6 in welding, dispensing, spraying and other fields, when you use other systems, the processing effect is not satisfactory or unable to complete the processing, please feel free to contact us;

There will be no pause between the instruction; action is very smooth, coherent processing without pause, this competition at home and abroad to any system in the same machine, or don't lose any of them.

When stepping motor is used in machinery, it can reflect the instructions of my control system more smoothly and smoothly.

Using AFDX05 special motion control chip, one can control 30 axis linkage at most;

• support standard G codes, G00, G01, G02, G03, G04, etc.;

Macro command programming, support SIN, COS, TAN, ASIN, ACOS, ATAN, SQRT and other functions;

3D arc interpolation; four axis circular arc interpolation;

Four axis linkage (cheap) or eight axis linkage (the price is slightly more expensive);

Offline operation;

Teach programming;

Manual programming;

New version of hardware ready to support SD card read-write or serial communication;

Yes, you can take step drive or servo drive;

Point movement function;

Six teaching speed: high speed, medium speed, low speed, micro motion, etc.;

The old version of the hardware supports connecting 4 to 8 ABZ incremental encoders, and the new version of the hardware does not support this functionality;

24 input port, 12 way output port, or 36 way input port, 20 way output port;

The standard configuration is to control 1 to 4 or 8 motor movements; custom can control up to 30 motors at most;

Input and output port test function;

Keyboard keyboard test function;

The power supply is 24V DC power supply;

The biggest disadvantage of our system is that there are 253 processing files, each processing file with at most 300 to 600 lines of G code statements. Efforts are being made to solve the problem of processing large files.

The system is constantly revised and perfected, and you should inquire about the latest changes.

Yunshan CNC continuously strive to design and produce products with the highest performance price ratio!

Product Image

Img 1

Send Inquiry to this Member

Related Products of this Company

This member assumes full responsibility for the content of this listing. DIYTrade accepts no responsibility whatsoever in respect of such content.

To report fraudulent or illegal content, please

click here.

China Suppliers Quick Searching:

,