| Model: | h10f |

|---|---|

| Brand: | sandvik |

| Origin: | - |

| Category: | Metallurgy , Mining & Energy / Metallurgy & Mining / Non-ferrous Metal Alloy |

| Label: | h10f carbide , h10f carbide strips , h10f |

| Price: |

US $186.6

/ KG

|

| Min. Order: | 1 KG |

| Last Online:19 Jul, 2016 |

H10F tungsten steel, H10F tungsten steel strip, H10F tungsten steel strip, H10F tungsten steel strip material, H10F tungsten steel material, H10F tungsten steel, H10F tungsten steel plate, H10F tungsten steel material, H10F tungsten steel sheet, H10F tungsten steel planks, H10F tungsten steel bars, H10F tungsten steel rod, H10F tungsten steel bars, H10F carbide, H10F carbide strip, H10F carbide strip, H10F hard alloy sheet, H10F carbide plate, H10F alloy sheet, H10F carbide slab, H10F carbide rods, H10F carbide rods, H6F tungsten steel, H6F tungsten steel strip, H6F tungsten steel strip, H6F tungsten steel strip material, H6F tungsten steel, H6F tungsten steel plate, H6F tungsten steel sheet, H6F tungsten steel slab, H6F tungsten steel bars, H6F tungsten steel rod, H6F tungsten steel bars, H6F carbide, H6F carbide strip , H6F carbide strip, H6F hard alloy sheet, H6F carbide plates, H6F alloy sheet, H6F carbide slab, H6F carbide rods, H6F carbide bar, PN90 tungsten bars, PN90 tungsten steel rod, PN90 tungsten steel bar material, PN90 carbide, PN90 carbide rods, PN90 carbide rods, PN90 carbide rods, DM80 tungsten steel bars, DM80 tungsten steel rod , DM80 tungsten steel bars, DM80 carbide, DM80 carbide rods, DM80 carbide rods, DM80 carbide rods, PCB tungsten steel, printed circuit boards with tungsten steel, tungsten steel woodworking, wood processing tungsten steel, dk20 tungsten steel, DK20 tungsten steel strip, dk20 tungsten steel strip, dk20 carbide, dk20 carbide strip

As a market leader in metal cutting, we are able to offer customers a variety of brands to meet their performance and product technical requirements. In order to meet the performance, corrosion resistance, hardness and toughness requirements, Sandvik Hard Materials will introduce the ultra-fine grain size of cemented carbide (6UF, 8UF, PN90, DM80), submicron grain size of cemented carbide (H3F , H6F, H6FF, H10F, H15F, H6N, H11N, H12N), DZ class grades (submicron combine the right amount of adhesive) and carbide coarse grain size and to market. Series of ultra-fine grade material quickly improve productivity and quality of our customers and become a market-driven material PCB tools.

Carbide Type:

WC-Co grades

This group of grades of WC and Co as the main element, but often add other elements to group parts result in better performance. These grades are due mainly containing cobalt and WC grain size is referred to as "tungsten cobalt", the flexural strength and toughness of cemented carbide in all types of changes in the most widely used, and has excellent wear resistance. Major applications such as carbide segments as follows:

Nano, ultra-fine grain and submicron grain grades

Such grades binder content of 3-10%, the grain size of not more than 1um, with a high hardness and compressive strength, and has excellent wear resistance and reliability. Because of its high hardness, wear resistance and sharp blade cutting of these characteristics, widely used in the manufacture of wear parts, metal cutting tools.

|

|

Coarse grains, coarse grains and coarse grains special grades

|

Material Description:

Sandvik has always been in a leadership position submicron grain carbide grade. The best example of that is our H10F grade is widely used in the field of cutting face milling, drilling, and band saw cutter, etc. and always in a dominant position. H10F carbide materials combined with a 10% cobalt and 90% tungsten carbide (WC), its tungsten carbide particles of 0.8 microns. H10F on several properties of hardness, toughness, wear resistance and forming a cutting edge sharpness and other materials to achieve a perfect balanced portfolio. H10F grade material in a very broad field of application is used to make carbide rotary tool, its uniform and stable microstructure is particularly suitable for many of today's coating material; In addition, the unique items add it without loss of toughness premise By also has good corrosion resistance. H10F grade material is also easy to weld, the advantage of easily processed, making him particularly suitable for metal cutting tools; such as when used in various types of welding tools, to ensure the edge sharpness and toughness, but also easy to weld.

H10F tungsten steel applications:

1: Can be used for machining steel, stainless steel, titanium, nickel alloys and other materials;

2: Can be used for processing of non-metallic composite materials and non-ferrous castings workpiece.

3: for low-speed cutting, high-speed to the rate (high speed steel) cutting and interrupted cutting and other processing methods;

4: it can also be used for processing hard wood, such as hard wood, high density board.

H10F physical and mechanical properties of tungsten carbide

|

grade |

hardness |

TRS |

grain size(WC) |

content(Co) |

density |

||

|

H10F |

HRA |

HV30 |

N/mm2 |

psi |

μm |

% |

g/cm3 |

|

92.1 |

1600 |

4300 |

623000 |

0.8 |

10 |

14.45 |

|

H6F carbide materials, its content of 6% cobalt, tungsten carbide particles of 0.8 microns, hardness 93.2HRA, density 14.9. Unique hardness and ultra-high wear resistance, low speed finishing some special product offers higher material protection.

PN90 carbide material is Sandvik developed a new type of ultrafine particulate material, its hardness 93.9HRA, tungsten carbide particles of 0.2 microns, is currently Sandvik has developed a high hardness carbide . Wear resistance and toughness to achieve the perfect combination of balance, in front of the world level of carbide materials.

DM80 tungsten carbide rod material, cobalt content of 8.5% tungsten carbide particles of 0.8 microns, hardness 93.3HRA, unique production process, hardness and toughness, more suitable material for the semi-finished products between 45-60HRC.

DK20 tungsten carbide strip, DK20 is a carpenter with a widely used carbide. It can be applied to most of the wood processing, and easy welding and grinding.

Mechanical properties of tungsten carbide cobalt

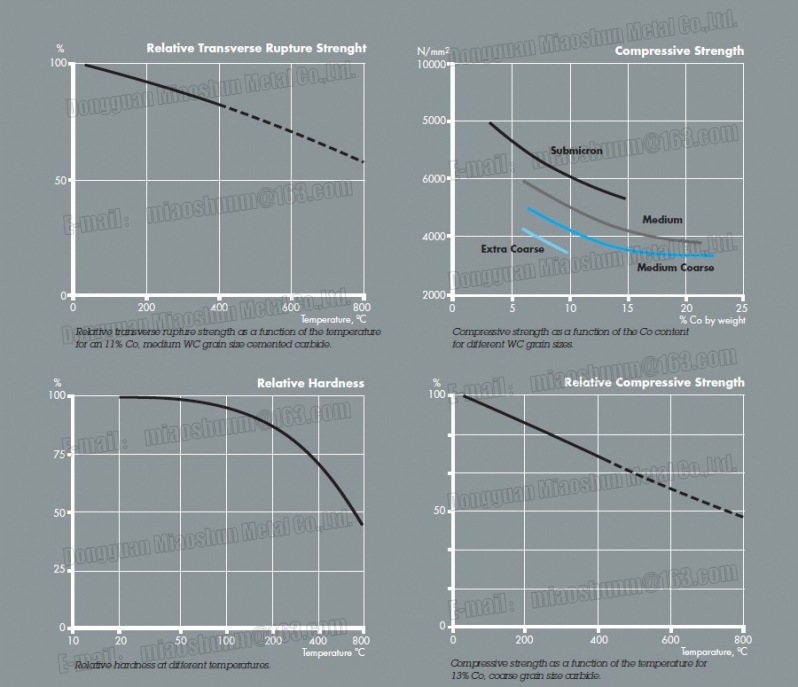

Cemented carbide has a very high compressive strength, which is one of the most useful properties.

Binder content and grain size, the higher the compressive strength. WC grain size is small and low grade binder content typical compressive strength approaching 7.000N / mm2.

And all engineering materials, the mechanical strength of the alloy at high temperatures will be reduced. This decline in the temperature higher than 600 degrees Celsius is still significant, and therefore at a high temperature using a cubic carbides or alloy binder appropriate.

The main performance of cemented carbide, the mechanical properties of hardness, flexural strength and fracture toughness.

As shown in the chart on this page, with the grain size and the binder content decreases the hardness increases. Unfortunately, it is always at the expense of reduced toughness. For practical abrasive products, hardness as a good measure of wear resistance standards.

Comprehensive product range

1: within certain specifications provide limit your stock to shorten product delivery time. We offer grinding bar, open tolerance with inner cooling holes and ordinary solid rod.

2: the company's scope of supply includes all blank and finished products, from simple grinding to precision polishing.

3: mass production of various size of the size of the strip.

Sandvik Hard Materials are ISO9001 and ISO14001 certification.

We strive to understand customer needs, working closely with our customers to find the right materials for their production processes, product design and technology, in order to improve customer productivity and exceed customer expectations. So far we have worked with many customers the product development and testing, and expect to have more partners. In our view, every cooperation and innovation is an opportunity to change the world.