| Model: | DN |

|---|---|

| Brand: | LUY |

| Origin: | Made In China |

| Category: | Industrial Supplies / Other Industrial Supplies |

| Label: | hermo treatment plan , Wood heat treatment , Thermo wood machine |

| Price: |

US $12000

/ pc

|

| Min. Order: | 1 pc |

| Last Online:20 Nov, 2015 |

Thermo wood treatment plant

This machine can effectively improve the dimensional stability and the anticorrosion property of timbers. Without any chemicals, the process of coking which have no harm to human and environment can make the wood antique color. This equipment solve the relation between coking process parameters and the effect of carbonization by the control of the carbonization temperature and holding time. The process parameters of the equipment play a decisive role to the performance of the coking wood. Our company designed and developed the automatic drying control programs by measuring and analyzing the color, quality, hydroscopicity, wet swelling property, mechanical property and chemical components of the coking wood under different conditions of carbonization. And the rationality of the equipment has reached the world advanced level.

Technical Parameters

| Model | Wood depth carbonization equipment |

| Size | The maximum diameter which our company can make is 4.5m. And the length is up to your Requirement. |

| Design temperature(℃) | 240 ℃ |

| Design pressure(Mpa) | 0.6Mpa |

| Working pressure(Mpa) | 0.3-0.4Mpa |

| Design vacuum degree(Mpa) | -0.098mpa |

| Material | 304 stainless steel |

| Heating method | Electric heating conducting oil cooling system |

| Cooling way | Forced circulation cooling system |

| Water way | Spray water and water vapor |

| Insulation way | External galvanized sheet, with 80mm insulation cotton |

| Heat distribution way | Circulating fan |

| Open the door way | Manual and electric dual open the door |

| Sealing method | Inflatable silicone seal (life 1--2 years) |

| Control method | PLC computer control |

| Safe method | Double-door safety interlock tank, tank three safety interlock |

| Alarm method | Ultrahigh pressure automatic alarm |

| Track label, bearing | 12th rail> 12 tons |

Detailed Images

Advantages

1. Full automatic control by computer.PLC automatic computer control system to ensure accurate and reliable control, add medium circulation device to ensure uniform heat treatment, carbonization treated wood fineness uniform, no smell.

2. The frame of the equipment is made of stainless steel to prevent corrosion. Stainless steel tank, corrosion resistance, durability, processing and flexible.

3. High precision and better effect of treatment. Six sets of security system to ensure safe operation of equipment.

4. Easy to operate, energy saving and environmental protection.

5. Using anaerobic carbonization. According carbonization needs to maintain an oxygen-free vacuum carbonized in the carbonization process, the temperature is between 160 ~ 230 ℃adjustable.

6. Suitable for mass production of high-end wood processing enterprises.

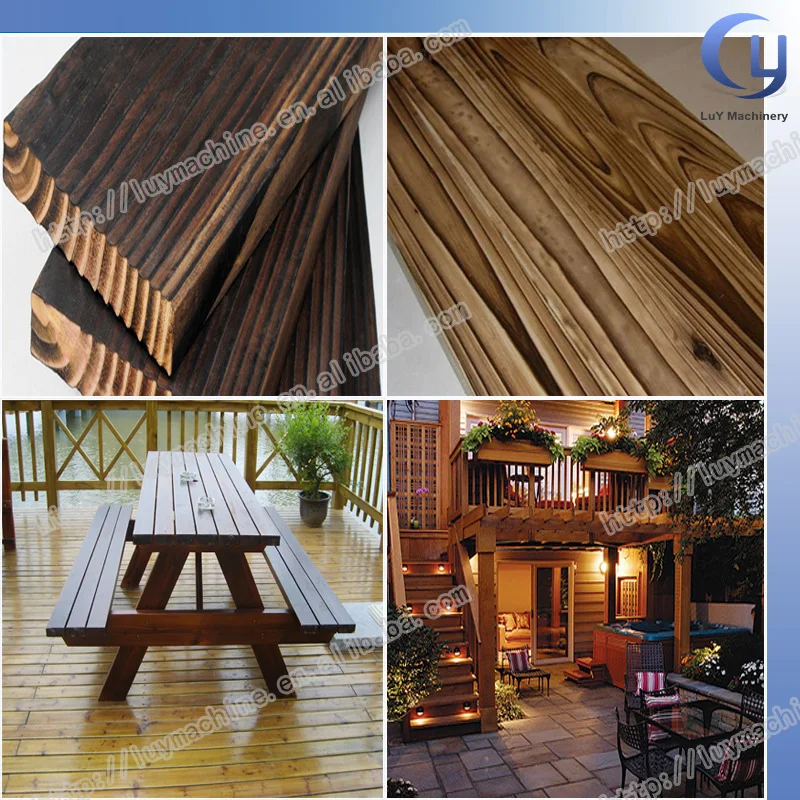

carbonized wood

What is depth carbonized wood?

The depth carbonized wood also called completely carbonized wood, homogeneous charring wood. It is the result of about 200 degrees high temperature treatment. Because of its nutrients are destroyed, it has better corrosion pest control function, due to its functional group water hemicelluloses be reorganized to make products with better physical properties.

The depth carbonized wood is truly green products.Although the product has fungicide and insect repellent properties, but it does not contain any harmful substances. It not only improve the life of the wood but also will not have any negative impact for the human body , animals and the environment.

The depth carbonized wood has nearly a decade of experience in Europe. It is the main substitute products after disable the CCA anticorrosive wood.

The depth carbonized wood widely used in many aspects of siding, decking, kitchen renovation, sauna decoration, furniture and so on.

What are the advantages of carbonized wood?

1. Strong corrosion resistance

Wood in the carbonization process, most of the fungus and all the insects were killed in the high temperature air. And in the condition of high temperature, its internal nutrition complex and severe chemical changes have taken place, degradation or restructuring. It can make the surviving bacteria die because of the loss of nutrition. That is to say, the wood will not be mildewed after carbonization.

2. Environmental Protection

In the whole process, wood only contact with steam and hot air, do not add any chemicals, maintain the natural essence of wood.

3. Purifying air

After carbonation, wood has the special function of carbon. It can absorb impurities which in the air, filtered air to improve the environment of people breathing.

4. Stability

In the high temperature carbonization process, the wood inside the hydrophilic factors are restructuring, reducing the moisture balance of wood, commonly known as "wet line", not easily affected by the surrounding environment. Widely used in a variety of wood products, wood siding, sauna boards and other wooden materials.

5. Color gorgeous, change a single species of a single color

In the carbonization process, the timber is heated uniformly. Action at high temperatures, the color of the wood changes, improve the environment overall taste.

What the carbonized wood used for?

The wood flooring is one of the main purposes. In addition, It can also be used to make into other outdoor products, such as tables and chairs, swing, grape trellis, huts and others

Company Information

Our company have three production lines to meet customers’ requirements ,20 senior engineers to design ,skillful welder to process the equipment ,24hours after-sales team to support. Our products have been sold to Russia, French, Peru, Uganda, Tanzania, Kenya and Burma.

Customer Visit

Packaging & Shipping

FAQ

1. What is max diameter we can do for you?

The maximum diameter which our company can make is 4.5m. And the length is up to your requirements.

2. How much capacity can you treat per tank at a time?

It is up to the diameter and length of the equipment designed by your demands.

3. Is the control system manual, semi-automatic or full-automatic?

Our basic control system is semi-automatic operation system, and we also supply full-automatic operation system.

4. Can we install the equipment by ourselves?

Of course, we will provide you with detailed installation information.

Contact us