| Model: | - |

|---|---|

| Brand: | LUY |

| Origin: | Made In China |

| Category: | Industrial Supplies / Rubber & Plastics Machine |

| Label: | rubber hose vulcaniz , hot belt vulcanizer , Rubber curing cham |

| Price: |

US $8000

/ pc

|

| Min. Order: | 1 pc |

| Last Online:20 Nov, 2015 |

Product Description

New trade assurance full automatic high temperature autoclave are divided into two series: steam vulcanizing boiler series and hot air vulcanizing boiler series. Each series has three heating mediums: steam, electric and conduction oil.

Our equipment which has advantages of stable and reliable performance is the most widely used steam vulcanizing boiler, the temperature, pressure and time can be controlled automatically and it also easy to operate. And the equipment can save 35% of energy than other traditional equipment.

Working principle for steam vulcanizing autoclave

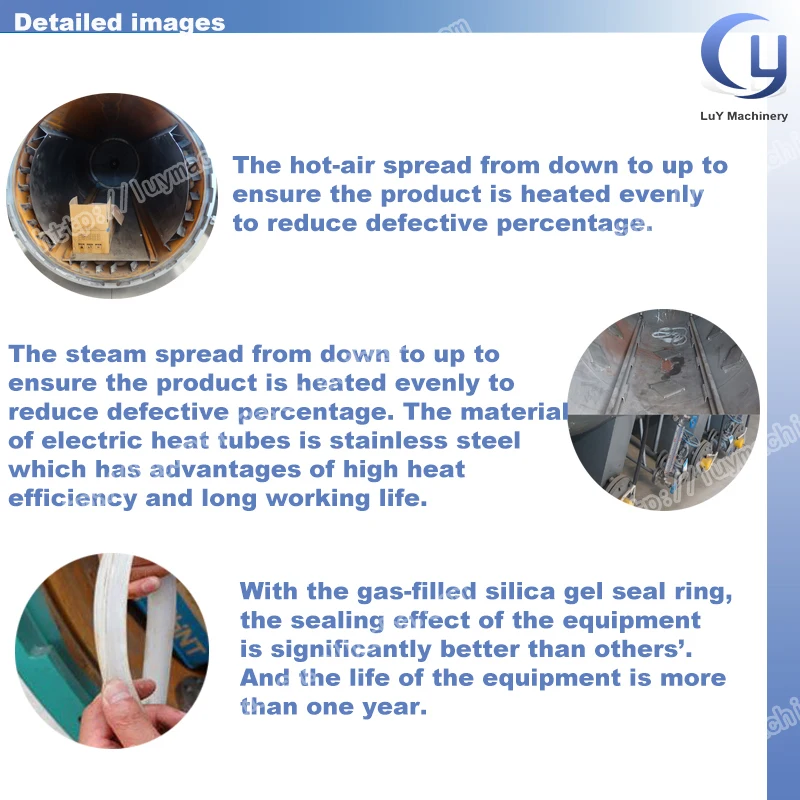

The steam enter into the steam diffusion tube by entrance of steam which at the bottom of the steam vulcanizing boiler and the entrance can be controlled by automatic valve. The steam diffusion tubes vertical arrangement in the bottom of the tank. The small holes which diameters are 3mm,4mm and 5mm on the steam diffusion tube are arranged according to certain rules and angel to ensure that the steam spread in the tank evenly. Thus it can prevent the different quality of the product because of the uneven steam. After set working procedures, the heating, heat preservation, vulcanization and etc can be finished by automatic control system. The equipment stop working and give alarm after all procedures finished.

Working principle for electricity steam vulcanizing autoclave

Electric heated tubes are arranged in the bottom of the tank according to certain rules, the heat exchanger linked the electric heated tubes and the water channel. The height of the sink is 5~15mm. The steam which produced by electric heated tubes and water spread from down to up evenly until turn into condensate water pour into the sink after touched the wall of tank and then heat again. The temperature of the tank evenly and the pressure has no error, so it can prevent the different quality of the product because of the uneven temperature and pressure. After set working procedures, the heating, heat preservation, vulcanization and etc can be finished by automatic control system. The equipment stop working and give alarm after all procedures finished.

Our equipment which has advantages of stable and reliable performance is a new type of vulcanizing boiler, the temperature, pressure and time can be controlled automatically and it also easy to operate. And the equipment can save 30% of energy than other traditional equipment.

Working principle for steam hot-air vulcanizing autoclave

The steam enter into the cooling fin which in the tank of the steam hot-air vulcanizing by two sets of automatic valve. The cooling finds arrangement in the tank according to the certain rules. The draught fan which in the back of the tank make the quantity of heat spread evenly by special temperature cycle plates. Heat cycle form even temperature field. Thus it can prevent the different quality of the product because of the uneven temperature and pressure. After set working procedures, the heating, heat preservation, vulcanization and etc can be finished by automatic control system. The equipment stop working and give alarm after all procedures finished.

Working principle for electricity hot-air vulcanizing autoclave

Electric heated tubes which controlled by N groups of separate switch are arranged in the bottom of the tank according to certain rules. Only keep one or two groups of electric heated tubes working after reached working temperature, so it can save the energy and reduce the cost greatly. The temperature of the tank evenly and the pressure has no error, so it can prevent the different quality of the product because of the uneven temperature and pressure. After set working procedures, the heating, heat preservation, vulcanization and etc can be finished by automatic control system. The equipment stop working and give alarm after all procedures finished.

Detailed Images

Thermal insulation method: Our equipment using external thermal insulation.

Thermal insulation material: Our equipment using glass silk and aluminum silicate.

The galvanized sheets which will not rust in ten years welded and fixed around the equipment and built in insulation cotton to ensure make full use of heat energy. The thickness of the insulation cotton which around the tank is 80mm and the thickness of the insulation cotton which around the head of the equipment is 60mm. It has advantages of easy to transport, long time use without deformation, good insulation effect and low cost.

Customer visit

Packaging & Shipping

Company Information

We have three production lines to meet customers’ requirements ,20 senior engineers to design ,skillful welder to process the equipment ,24hours after-sales team to support. Our products have been sold to Russia, French, Peru, Uganda, Tanzania, Kenya and Burma.

Application field

Contact us