| Model: | L |

|---|---|

| Brand: | LUY |

| Origin: | Made In China |

| Category: | Industrial Supplies / Food, Beverage & Cereal Machine |

| Label: | industry cooking pot , Jacketed kettle wit , industrial kettle fo |

| Price: |

US $800

/ pc

|

| Min. Order: | 1 pc |

| Last Online:20 Nov, 2015 |

Product Description

Feature

This machine using a molded stainless steel pot to ensure the pot is smooth. It can be heated by steam, liquefied petroleum gas, natural gas, conducting oil and electromagnetic.

• Using special planetary stirred, make the stirrer contact with the pot body fully, make sure the pot without stirring blind Angle.

• Using advanced transmission and seal structure to ensure the pot clean and hygienic.

• Perfect use variable speed drives and cycloid machine and tilt drive combination ,increases the drive torque,the stirring speed can be adjusted in the range of speed. hydraulic lift and turn pot, save more time and labor.

Advantages

This machine has advantages of big heating area, high thermal efficiency, uniform heating, material heating up fast, easy to control the heating temperature and so on. Widely used in meat, fried stuffing, sauces, prepared foods, candy, pharmaceutical, dairy, beverage, canned food, can also be used in large restaurants or canteens porridge boiling water, cooking purposes.

Technical Parameters

| Volume(L) | Diameter(mm) | Motor power(Kw) | Revolution | Autorotation | Agitating form | Lift/turn pot form | Heating form |

| 200 | Φ900 | 0.75+1.5 | 6.7-33 | 14-69.3 | planetary/scraped | Automatic/ hydraulic | steam/gas |

| 300 | Φ1000 | 0.75+1.5 | 6.7-33 | 14-69.3 | planetary/scraped | Automatic/ hydraulic | steam/gas |

| 400 | Φ1100 | 0.72+2.2 | 6.7-33 | 14-69.3 | planetary/scraped | Automatic/ hydraulic | steam/gas |

Classification

• According to the sealing method divided into no cover type, flat cap type and vacuum type.

• According to the arts demand divided into With stirring type and without stirring type.

• According to the heating method divided into steam heat type, electric heat type, gas heating type and electromagnetic heating type.

• According to the structure divided into tilting-type and stationary type.

Advantages

This machine have advantages of big heating area, high thermal efficiency, uniform heating, shorter liquid material boiling time, easy to control the heating temperature, good looks, easy to install, easy to operate, safe and reliable. Widely used in various food processing, it can also be used in large restaurants or canteen soup, cook, stew, porridge and other food processing to improve quality, working time and working conditions.

Feature

1. Using steam heating, keep top pot vacuum, continuous variable speed, turbine and gear combination drive, increasing the moment of force.

2. Using PTFE scraper agitator, agitator and the pot body full contact to ensure that no dead angle.

3. Open cover, unloading and reset controlled by the hydraulic automatic system, easy to operate.

4. Vacuum working can reduce the operating temperature, especially for heat-sensitive materials, avoiding the deterioration of color and taste, maintaining the original color, smell and taste of the raw material.

5. High efficiency, low energy consumption, short working time.

Technical Parameters

| Volume(L) | Mixing motor power(KW) | Turn pot motor power(KW) | Stirring rate(r/min) | Stirring form | Turn pot form | Heating method |

| 300L | 3 | 0.75 | 13-66 | Scraping | Automatic | Steam |

| 400L | 3 | 0.75 | 13-66 | Scraping | Automatic | Steam |

| 500L | 3 | 0.75 | 13-66 | Scraping | Automatic | Steam |

| 600L | 3 | 0.75 | 13-66 | Scraping | Automatic | Steam |

Feature

1. Using coil steam cycle indirect heating to make temperature more even.

2. Cooking soup can be continuous use, save energy.

3. With insulation, prevent the heat loss and worker burns.

4. The door adopts hydraulic quick open structure, and has a limit and interlock function.

5. Using inflatable seal. Installed the lens to ensure add soup in time.

Detailed Images

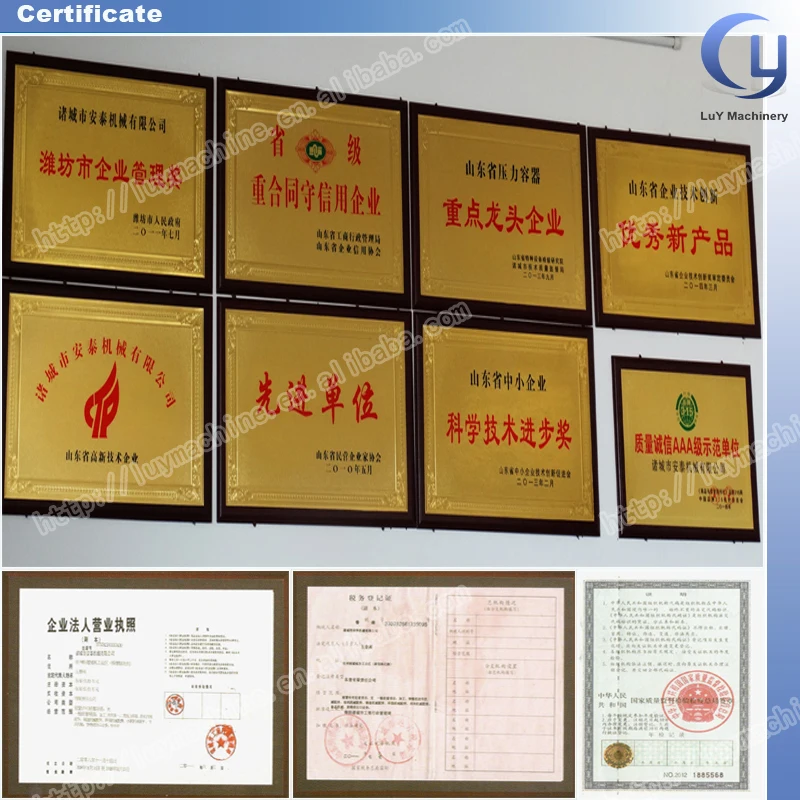

Company Information

Our company have three production lines to meet customers’ requirements ,20 senior engineers to design ,skillful welder to process the equipment ,24hours after-sales team to support. Our products have been sold to Russia, French, Peru, Uganda, Tanzania, Kenya and Burma.

Contact us