| Model: | 028 |

|---|---|

| Brand: | Kaxite |

| Origin: | Made In China |

| Category: | Construction & Decoration / Heat Insulation |

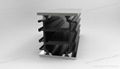

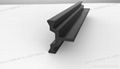

| Label: | polyamide66 , aluminium profiles , heat break strip |

| Price: |

US $0.45

/ m

|

| Min. Order: | 1 m |

| Last Online:29 Jul, 2016 |

Kaxite Energy-saving Materials Technology Co.,Ltd.was developing since 2001. We design and develop high-precision thermal insulating struts for aluminium profile customers, and successfully made great achievements for the field of thermal insulating window systems, the width of shapes were ranged from 10mm to 60mm or even wider and more complex. We built our first workshop for the division in 2003, which was also located in Jiangyin, Jiangsu, China. Production Capacity of 550,000 meters per day for common specifications. Own Granulation Capacity of 27 tons per day. We're diversifiedly developed and dedicated in designing and developing series of energy-saving materials, such as PA thermal insulation strips that used in heat break aluminium profiles and energy-saving window systems, EPDM/ABS/PE/PVC extruded profiles, nylon chain guide instead of PE material for automatic production line...

This product is applied to facade aluminium profiles, cutting dies required.

We're the first one who realized the Hard Cold Extrusion for polyamide thermal breaks, high precision, excellent performance, and high capacity.

We use the EDM cutting to ensure the smooth surface of polyamide profiles.

We control the best (most suitable) quantity on the dies, ensure to meet the delivery time, and best quality via best speed for nylon materials flowing in the extruder machine.

The time for cutting dies will be only 10~30 working days.

PERFORMANCE

The performance of thermal barrier strips are in line with the Chinese standard GB/T 23615.1-2009 and the European Standard EN 14024:2004, for KAXITE series, the performance is rather higher than the standard value.

RAW MATERIALS

For quality, the most important thing is to control the performance of the raw materials, as we have to ensure the expensive but indispensable additives (e.x. Antioxidants & Anti-aging agents) were contained in the mixture. We have our own capacity of granulation for PA66 GF25 and many other kinds of plastic granules. We're the only one who used the technology of Vacuum Drying for the polyamide, which could highly improve the natural performance of the nylon granules.

We have series of brands, corresponding to different raw materials. For domestic series, they will be the domestic new PA66 and short chopped fiberglass, for KAXITE series, they will be the imported Dupond PA66 and short chopped fiberglass, which has rather better performance than the standard required.

CUTTING DIES

Mostly we could finish the development of new products in 15 days.

The hardest thing is not thinking, but realizing. Most customers were upset that nobody could develop the shapes that they designed, some counterparts even came and looking for help to our workshop. We developing and cutting new dies for our customer, of course we never failed to develop any shape for our customers.

DELIVERY

We have more than 40 extruders, production capacity of 550,000 meters per day. For common specifications, they‘re ready in stock, if customized, mostly the production could be finished in 7 days.

PACKAGES

For all specifications/shapes, they could be packaged in linear, the length will be 6 meters, or customized.

For the Shape "I", "C", and some simple shapes, they can be packed in rolls. 400-600 meters/roll

Currently, our products are sold to Ireland, India, Denmark, Bangladesh, Spanish, Germany, Russia, USA …

Thanks & Best Rgds

Overseas Sales Manager

Amanda

From Kaxite Energy-saving Materials Technology Co., Ltd.

No.55 Changshan Rd, Jiangyin, Wuxi City, Jiangsu Province,China(214400)

Web:www.kaxitech.com

Skype/Whatsapp:+86-15295539599

E-mail:amanda.zhou@kaxitech.com

Facebook Homepage:Kaxite Technology@amanda.kaxitech