| Model: | YKQ-1L |

|---|---|

| Brand: | YLK |

| Origin: | Made In China |

| Category: | Industrial Supplies / Mining Machine |

| Label: | roll ball mill , ball mill machine , laboratory mill |

| Price: |

-

|

| Min. Order: | 1 set |

| Last Online:09 Aug, 2016 |

The YKQ Laboratory roll mill machine is a kind of sample pulverizing machine, which can grind coarse particles into micro powders. It can mill the materials from 10mm maximum into 15um minimum powder. This machine can deal 0.3L to 10L material per time depends on the model choose.

Detail Application in laboratory or industry

1. Ceramic.

2. Pigment. (Paint/ink/color/coating)

3. Agriculture. (Tea / Chinese herb / plant / Coffee beans / etc)

4. Pharmaceutical production (Medicine/Drug)

5. Solid waste treatment. (Soil / metal / Plastic)

6. Mine. (Ore/stone/metal/litharge/lithium/alumina/coal/chrome/graphite/ lead/etc)

7. Construction ( Stone / glass / cement / concrete / sand / slag )

8. Powder metallurgy; / Abrasive materials;

9. catalysts production and recycling;

10. Chemical.

11. Others ( Comestic / makeup / clinker / pearl / linestone / others )

Note: If the material you need to grind is not included in the list above, please kindly contact the sales for confirmation. Normally speaking, our machine can mill all the materials except the really hard ones. For different material milling, please choose the appropriate milling jars as sales recommended.

The Input & Output Size of material

For fragile materials:

Input size: 10mm maximum

Output size: 15um minimum

Time needed: About 3hours per time milling

For hard materials:

Input size: 3mm maximum

Output size: 15um minimum

Time needed: Depends on the material hardness.

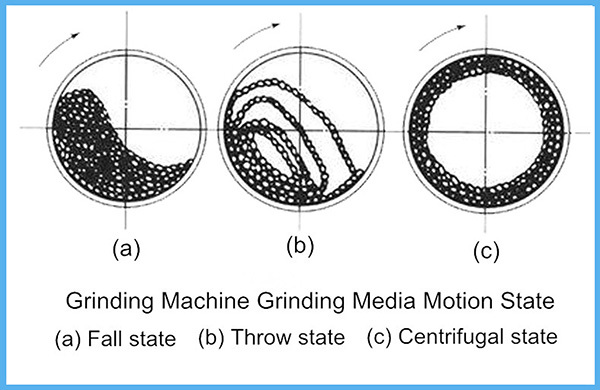

Working Principle

While the roll ball mill machine starts working, the axises of machine starts to rotate and makes the jars on it rotating together rapidly. During jars motion, the material & milling balls inside jars ascend to certain height and then drop along the parabola whereabout by gravity. Eventually, materials inside it will be milled into powder by the repeated crushing with the balls & jar wall.

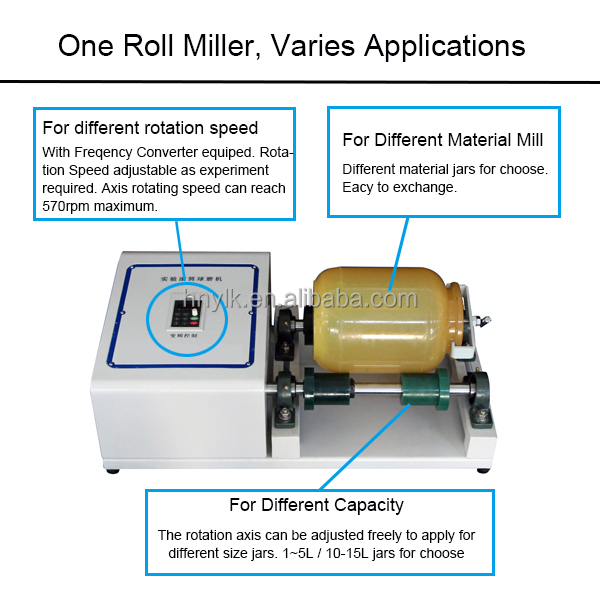

Machine Characteristics

1. Compact Structure; Easy to operate;

2. Efficient working; Uniform grinding particle size by horizontal milling;

3. Applied to different size jars by adjusting the movable axises;

4. Convenient to exchange jars, applied for wet/dry mill.

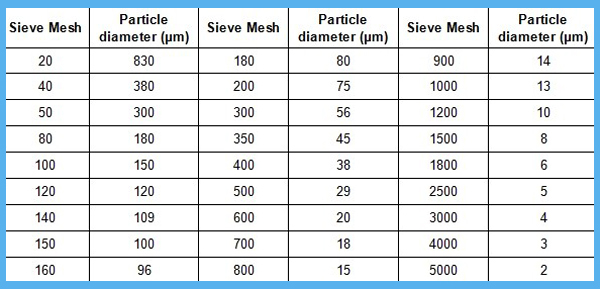

About sieve/screening

Every YLK Ball Mill Machine can be equipped with a round frame sieve. While grinded powder passing through the sieve, the particle can be classified into different sizes. The screen has 10 types, including 20/40/60/80/100/120/140/160/180/200 sieve number. You can get different size powder by choosing the appropriate screen.

Matches between sieve & particle is as followed:

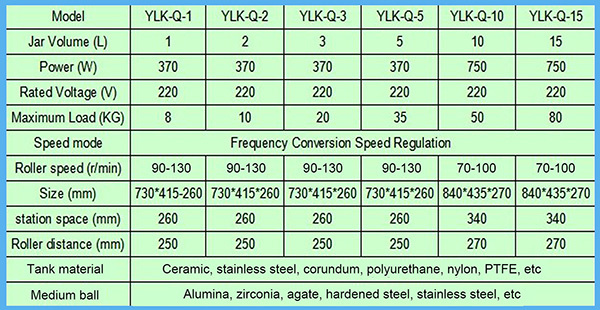

Other Model Types

Remark: (1) Single tank, feeding grain size: ≤10MM diameter, output grain size: 15μm minimum diameter.

(2) Loading rate of ball mill can not exceed 70% of the effective volume of grinding cylinder