| Model: | DY 5T 10T 20T |

|---|---|

| Brand: | DY |

| Origin: | Made In China |

| Category: | Industrial Supplies / Rubber & Plastics Machine |

| Label: | pyrolysis plant , tyre pyrolysis plant , recycling plant |

| Price: |

US $50000

/ pc

|

| Min. Order: | 1 pc |

| Last Online:06 Aug, 2016 |

Waste tyre recycling pyrolysis plant

Doing waste tyre recycling pyrolysis plant method is a technique which heats tyres in a sealed reactor. In the reactor the tyre is softened after which the tyre continuously into oil by cooling system.

The most important is pyrolysis plant reactor, DOING waste tyre pyrolysis plant reactor has some advantages as below:

1. The raw material of reactor is Q245R. Q245R is mainly used for pressure vessel because it can be continuously heated for long time. To keep a long service life.

2. Auto-welding with carbon arc air gouging technique.

3. The reactor is fully covered by thermal insulation. Heat preservation effect is good.

4. The gear is separated from the reactor. It avoids deformation after being heated for long time. Even it is broken you only need to change the gear. The maintenance cost is low.

5. There is a safety net inside the reactor. It prevents the raw materials going to accessories and avoiding blocking.

6. There are spiral plates inside of the reactor cab help to auto-feed and slag.

7. Feed port is round shape. It can work with auto-feeder. It helps you feed more raw materials and improve working efficiency.

Waste tyre recycling pyrolysis plant is a good project for recycling centers, collection organizations etc. DOING waste tyre pyrolysis plant adhere to constantly updated product, guarantee high-quality product and offer full-service for our clients. DOING is your trustworthy partner, welcome to contact us.

| Technical parameter of waste tyre recycling pyrolysis plant | ||||

| No. | Items | Contents | ||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Raw material | Waste tyre | Waste tyre | Waste tyre |

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 30T | 35T |

| Prepared by customer about waste tyre recycling pyrolysis plant | ||

| No. | Item | Consumption |

| 1 | Coal(for choice) | 500kg/day |

| 2 | Wood(for choice) | 800kg/day |

| 3 | Natural gas(for choice) | 100-150kg/day |

| 4 | Oil(for choice) | 300-350kg/day |

| 5 | Electricity | 244kwh/day |

| 6 | Water(recycled) | 60㎥ /month |

| 7 | Total power | 19kw |

| 8 | Land area | 35m*15m |

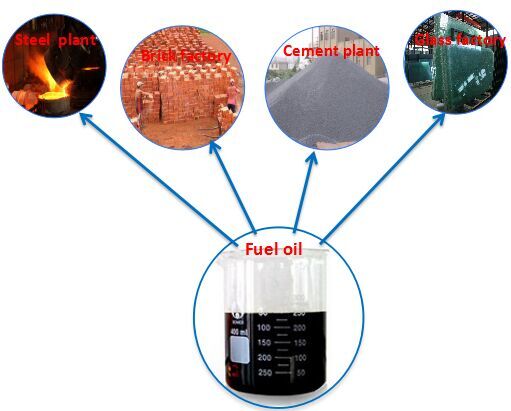

Fuel oil application

The main application of oil products produced by our waste tyre recycling pyrolysis plant is the fuel oil that is wide used for industrial and commercial purposes. 40% to 45% oil of the amount of recycled scrap tyres can be carried with licensed tanker trucks.

Contact: Ms Bonnie

Phone: +86-371-5677 1821

+86 15893800169

Skype: bonniezhao2

Email: oilmachine@doinggroup.com

www.wastetireoil.com

www.doinggroup.com

www.continuouspyrolysisplant.com