| Model: | jf |

|---|---|

| Brand: | jf |

| Origin: | Made In China |

| Category: | Industrial Supplies / Machinery / Separation Equipment |

| Label: | sorting , Separate , recycling |

| Price: |

¥100000

/ set

|

| Min. Order: | 1 set |

| Last Online:20 Sep, 2016 |

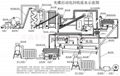

Circuit board to take off the tin electronics equipment

With electronic components of the circuit board by conveyor to close the wind into the feeding roller and feed preheating chamber.

1, close your wind feeding roller: to prevent the cold air from there into the machine. Closed wind feeding roller conveyor feeding devices below. Conveyor belt and closed wind under linear velocity, feeding roller diameter to evenly into the material.

2, feed preheating warehouse: inlet is equipped with double heat shield to prevent heat leak, into the waste circuit board through the machine here to waste heat by more than 200 degrees, the preheating temperature and exhaust of the material. After cooling discharge of waste gas from the warehouse top of negative pressure suction, and through the other exhaust gas treatment equipment for processing. Material after preheating through lateral vibration feeding, material into the heating roller to remove waste tin electronic components.

Material separation drum sieve into the heating, the heating separation drum screen for large middle heater, drum sieve sieve plate can change according to the requirements of different aperture sieve plate. The separation of the outer edge of the drum screen has double insulation cotton, heat preservation and collection of circular cylinder off tin and electronic components, intermediate heating rod put the stainless steel roller heated to above 300 degrees, because the melting point of tin alloy at 220 degrees, the material into the heating roller and melted the tin in the drum tilt Angle and the rotation speed can be adjusted according to the material, the tin and tin shaker, the electronic components to the point. Material from the left to enter, the right side of the discharge, the discharge speed can be adjusted through the rolling speed and Angle. While most of the material in the back of tin and electronic components, drop through friction to make electronic components and pipeline by dropping it on a tin of vibrating screen,

Circuit board of the separated by a heating roller enters from the right side of the entrance, the heating temperature is above 300, roller mesh can follow change, but the aperture drum diameter slightly larger than a heating, through the transformation of roller tilt Angle and the stirring speed will not clean separation of tin and small electronic components for secondary separation, fall into the pipe into the tin in the vibrating screen, after the separation of circuit boards and electronic components by changing the Angle and speed circuit boards and large electronic components into the pipeline into the vibrating screen points board, circuit board and electronic component separation.

Fall into the points and small electronic components of tin sieve through tin tin vibration screening to small electronic components and separate out side by side.

Fall into the circuit board of the vibration sieve plate and big electronic components through the sieve separation circuit boards and electronic components sorting out the side by side.

The device outer for double insulation design, prevent the temperature loss, save energy consumption.

The device containing waste gas exports the back-end and exhaust gas treatment device, again for exhaust gas purification, discharging standard. Tin rate can reach about 99% off the equipment, electronic components rate can reach about 95%. Through this device can take electronic components of the circuit board is divided into: solder, electronic components, electronic components and circuit board larger.

Company commitment: the company has sales of circuit board to take off the tin to electronic equipment with perfect after-sales service, one year warranty, life-long maintenance, thoroughly solve your trouble back at home, please rest assured purchase!

Circuit board to take off the tin electronics equipment