| Model: | RX-005 |

|---|---|

| Brand: | Rongxin |

| Origin: | Made In China |

| Category: | Metallurgy , Mining & Energy / Metallurgy & Mining / Metal Mineral |

| Label: | electrode paste , soderberg paste |

| Price: |

US $200

/ Ton

|

| Min. Order: | 1 Ton |

| Last Online:08 Mar, 2016 |

Overview

Specifications

Place of Origin:

Henan, China (Mainland)

Brand Name:

RONGXIN CARBON

Model Number:

RX-001

Application:

Submerged Arc Furnace

Shape:

Carbon Blocks

Dimensions:

As Consumer's Request

Product Type:

Carbon Electrode Paste

C Content (%):

99%

Working Temperature:

180

S Content (%):

0.005%

N Content (%):

0.0015

H Content (%):

0.01%max

Ash Content (%):

2% --3.5%

Volatile:

9.5%--15%

Color:

Black

Technology:

Automatic batching

Advantage:

High Compressive Strength

Size:

As costomer's request

Type:

Carbon Products

Ash:

2% min

Surful:

1 max

Plastivity:

8-16%

Bulk Density:

1.38 min

Compressive Strength:

30 Mpa min

Packaging & Delivery

Packaging Details:

Ton bag,or as customers' request.

Delivery Detail:

Shipped in 10 days after payment

Company Introduction

Automatic batching , 24 years of production experience

Rongxin carbon products Co.,LTD established in 1992, after twenty years development, it has formed the calcined coke, electrode paste production as the core, pre-baked anode and anode scrap, graphite electrode, carbon brick coal, petroleum coke, forging and other products for the main direction of the management pattern.

Company has an annual output of 150000 tons of petroleum coke, electrode paste production capacity.In terms of electrode paste production, our company to realize automatic batching, kneading, molding, not only can reach 200000 tons of production capacity, also can ensure the quality of the products.

Our company produces the electrode paste with unique formula and advanced production equipment, make up for the gaps in the domestic market.

Product Introduction

Carbon Electrode Paste/ Electrode Paste

What is Carbon Electrode Paste?

Carbon Electrode Paste is a self-baking electrode used in submerged arc furnaces for delivering power to the charge mix. Electrode Paste is added to the top of the electrode column in either cylindrical or briquette form. As the paste moves down the electrode column the temperature increase causes the paste to melt and subsequently bake forming a block of electrically conductive carbon. Electrode Paste is essentially a mix of Electrically Calcined Anthracite (ECA) or Calcined Petroleum Coke (CPC) with Coal Tar Pitch.

Product Items

|

Specification |

Ash %(max) |

V.M. %(max) |

Restivity%(max)μΩm |

Compressive strength Mpa %(min) |

Volume density %(min) |

|

Airtight Electrode Paste-1 |

4.0 |

12.00-15.50 |

65 |

18 |

1.37g/cm3 |

|

Airtight Electrode Paste-2 |

6.0 |

12.00-15.5 |

75 |

17 |

1.37g/cm3 |

|

Standard Electrode Paste-1 |

7.0 |

9.50-13.50 |

80 |

22 |

1.37g/cm3 |

|

Standard Electrode Paste-2 |

9.0 |

11.50-15.50 |

85 |

21 |

1.37g/cm3 |

|

Standard Electrode Paste-3 |

11.0 |

11.50-15.51 |

90 |

20 |

1.37g/cm3 |

|

Chemical Electrode Paste |

11.0 |

11.0-15.5 |

90 |

18 |

1.37g/cm3 |

Product Details Show

Why Choose Us

1. 24 years old factory;

2. Annual production capacity is more than 200,000 tons;

3. 10000 CBM factory;

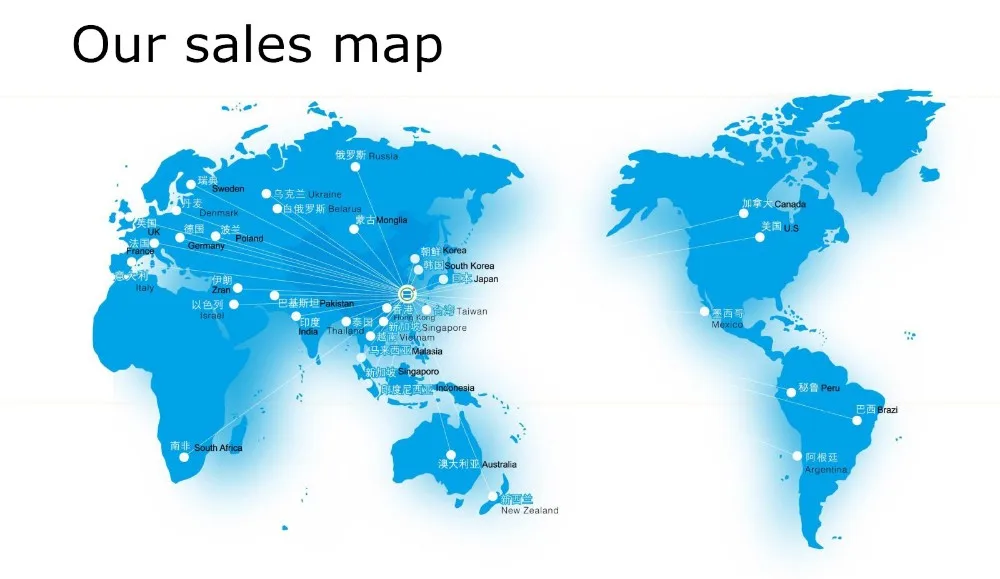

4. Exported to Iran, Indonesia, India and so on countries.

Our Advantage

RongXin Carbon Electrode Paste

1、Fully automated batching, crushing, mixing, kneading, molding, quality assurance, strict control of ash content, volatile, ensure low resistance and high strength.

2、Rongxin electrode paste in the pursuit of quality assurance in alloy production low consumption of this product, so as to improve the economic benefit of -arc furnace production.

3、High quality, low ash content, low resistivity, media V.M, high copressive strength.

4、Annual production capacity is more than 200,000 tons min.

FAQ

A.How to choose a high quality electrode paste

1、choose a manufacture

2、Inspect the size of the factory, the production equipment.

3、RongXin carbon since 1992,output two hundred thousand tons of electrode paste annuoual

B、Soft and hard to break

1、Hard broken is caused after electrode paste sintering strength is not enough;

2、Hard-off after the electrode paste firing resulted from insufficient strength; soft-off is not as fast as the rate of consumption electrode sintering, rapid decentralization, the electrode is not fully sintered electrode can not afford the lower portion of tensile and side impact, resulting in fracture.

3、RongXin carbon adopt automatic production,ensure the quality of products, so as to avoid soft and hard break

Contact us