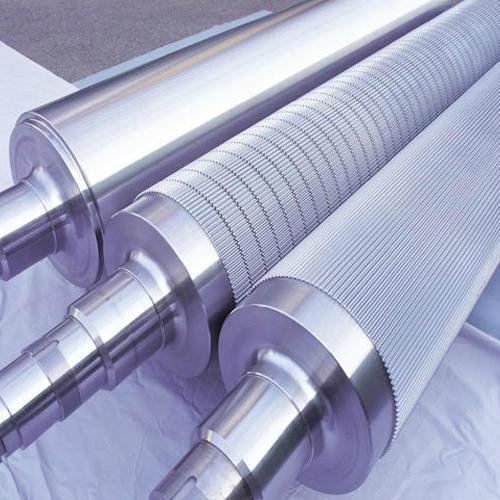

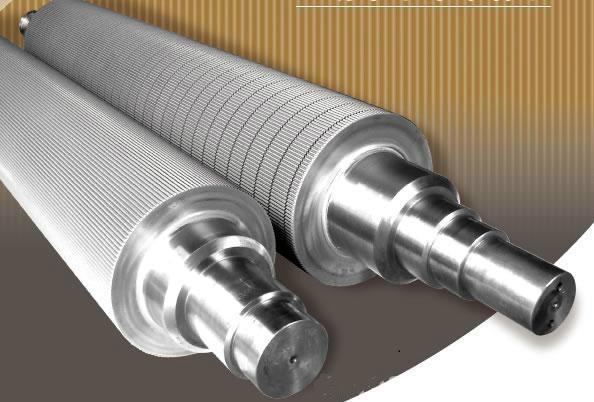

High Quality UV/ a~F Flute Corrugated Roller

Product Description

High Quality A, B, C, D, E, F Flute Corrugated Roller

Machine Description

1. The corrugated roll is made of high quality alloy steel. The technology comes from war industry.

2. It's made by high precision CNC corrugated roll grinding machine from the USA. The quality is very high.

3. It is treated by special corrugated roll surface treated technology. The hardness is very high.

4. High-speed corrugated roll with big diameter. The maximum working speed is 300m/min.

5. Gear type: UV,V. Flute type: A, B, C, BC, D, E, F optional.

6. Fingerless suction and inner suction are optional.

7. We are engaging in design ,repair, manufacture all kinds of corrugating roll

Technical Parameter

1. Intermediate Frequency Corrugated Roll

1.1 tooth shape: UV, V, alike V type

1.2 tooth height: 0.9-5.5mm

1.3 process length: Max. roller length 2800mm

1.4 Process diameter: Φ 100mm~Φ 500mm

1.5 Material: made in China, 42CrMo~50CrMo

1.6 hardness: ≥ HRC55°

2. Laser Corrugated Roll

2.1 Surface hardness: above HRC60°

2.2 Character of laser quenching: For the same material, the metallographic structure is more refined. And it is more durable than the traditional quenching process.

2.3 It won't enlarge the surface crack. It is the best process to repair the old roller.

2.4 The depth distribution of the quenching layer is that the top of the tooth is thick and the side of the tooth is thin. It can effectively solve the problem that the main wearing part of the roller is the top of the tooth.

3. Special Material Corrugated Roll

3.1 Hardness: above HRC62°

3.2 Long life-span: The life-span is above 50% longer than the roller made by medium carbon chromium molybdenum steel.

3.3 Low cost: The price is only 20% higher than the roller made by medium carbon chromium molybdenum steel.

4. Tungsten Carbide

4.1 Surface hardness: above HRC70°

4.2 The flute height is not easily wearing. So, you needn't change the rollers frequently. It uses the specially designed flute type.

4.3 It can save the consumption of the corrugated paper.

5. Specifications of Corrugated Roll

| |

A |

C |

B |

C |

D |

E |

F |

G |

Other |

| Flute |

UV |

UV |

UV |

UV |

UV |

UV |

UV |

UV |

Test Design |

| Corrugated Counts |

34±2 |

38±2 |

44±2 |

50±2 |

66±3 |

90±10 |

124±10 |

185±12 |

Test Design |

| Corrugated Lengths |

4.4-4.9 |

3.6-3.9 |

3.0-3.4 |

2.6-2.9 |

1.9-2.1 |

1.1-1.5 |

0.7-0.8 |

0.5-0.65 |

Test Design |

| Shrinkage |

1.51-1.59 |

1.44-1.51 |

1.42-1.49 |

1.36-1.42 |

1.40-1.41 |

1.29-1.39 |

1.22-1.26 |

1.20.-1.25 |

Test Design |

Product Image

Img 1

Img 2

Img 3

Img 4

Img 5

Send Inquiry to this Member

Related Products of this Company

This member assumes full responsibility for the content of this listing. DIYTrade accepts no responsibility whatsoever in respect of such content.

To report fraudulent or illegal content, please

click here.

China Suppliers Quick Searching:

,