| Model: | - |

|---|---|

| Brand: | Kuangshan |

| Origin: | Made In China |

| Category: | Transportation / Logistics / Lifting Systems |

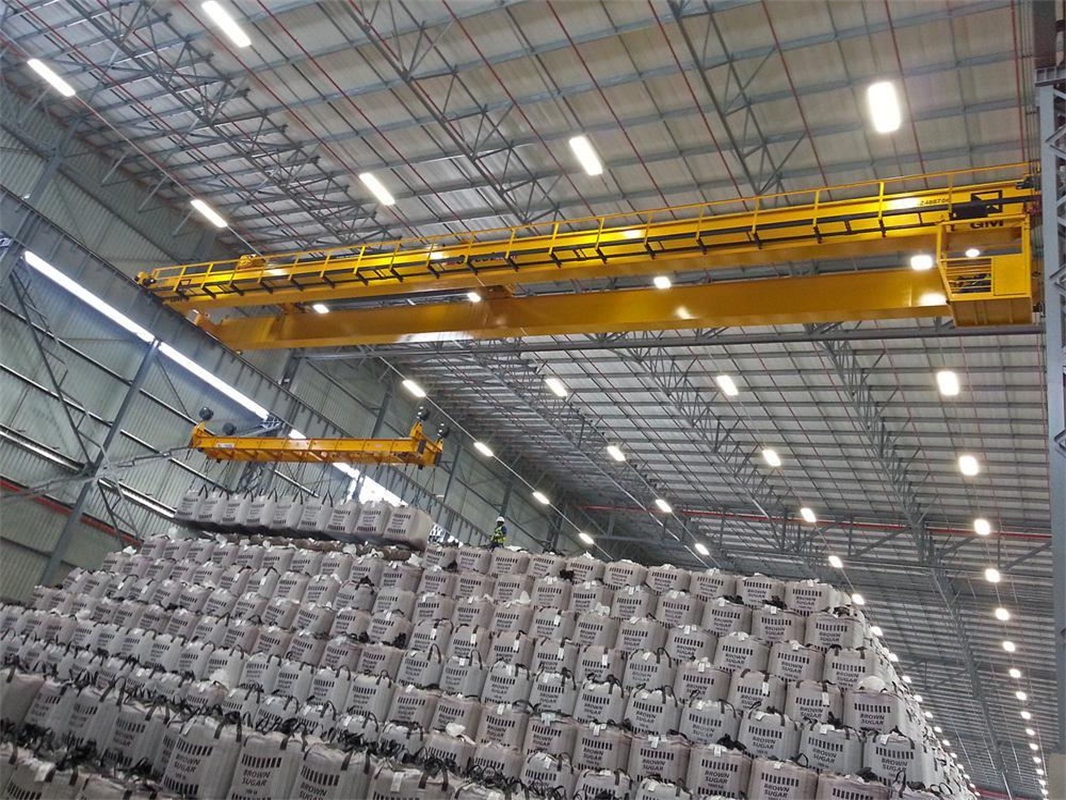

| Label: | overhead crane , gantry crane , intelligent crane |

| Price: |

US $5000

/ set

|

| Min. Order: | 1 set |

| Last Online:13 May, 2017 |

Kuangshan Crane Group Kuangshan Crane Group is one of top crane manufacturers in China, since 1981, has been manufactured crane machine for more than 30 years, specialized in overhead crane, gantry crane, grab crane, explosion proof crane, electric hoist and related products, widely service in construction, warehouse, shipyard, mine, metallurgy, foundry etc. We supply service of Crane production,Overhead bridge crane; installation, modification and maintenance, and have licenses issued by the General Administration of Quality Supervision, Inspection and Quarantine.

Digital Intelligent Control Crane uses advanced multi-CPU processing technology, achieve three-phase zero switching and three-phase zero off technology, is mainly used for starting, speed adjust, braking of lifting mechanism, translation mechanism, multi-motor drive mechanism, rotary mechanism, can monitor and manage Digital Intelligent Control Crane safety status, provide Cranes real-time operational data, analysis and process Crane fault, operation and maintenance, provide comprehensive, timely data assistance to help maintenance personnel to monitor and maintain the Digital Intelligent Control Crane machine.

Features

1. The current zero automatic breaking technology, Intelligent Crane electric system life is 10 times of traditional Crane.

2. Internet networking and encryption wireless remote control

3. Start smooth, reduce impact

4. Energy saving and reducer pollution, zero start, zero off, easy to install, good maintenance

5. Real time monitoring, data collecting, analysis and processing

Compare with traditional Crane

Control mode

Traditional Control Crane control mode adopts centralized control mode, a large number of cables, wiring complexity, and also greatly reduces the system reliability.

Digital Intelligent Control Crane reduce the drive, measure and control cable to minimize, improve reliability, reduce costs, simplify maintenance, set the operation, measurement, protection, control, communication as a whole, achieve a transparent control.

Electric Components

Traditional Control Crane control part contactor is easy to break by electric arc during power off, failure and fever, and impact motor and contactor, reduce electric system life, affect power quality.

The Digital Intelligent Control Crane control system can solve the related problems during Crane control and operation, prolong the switch and electrical system life, and improve the power quality.

Please leave your message,We will contact you soon!