| Model: | - |

|---|---|

| Brand: | cooking oil processing machine |

| Origin: | Made In China |

| Category: | Agriculture & Foods / Processed Food / Edible Oil |

| Label: | peanut oil machine , oil making machine , peanut oil refinery |

| Price: |

US $35000

/ set

|

| Min. Order: | 1 set |

| Last Online:27 Jun, 2018 |

1. Introduction of peanut oil making machine:

Three parts must have in this peanut oil making process line, prepressing, leaching(extracting) and refinery.

First, we need to press oil seeds get crude cooking oil and cake.Then the meal will be send to solvent extraction workshop to extract oil from cake.After this process, you will get cooking oil and meal. At present, Four grade of edible oil have, different oil grade have different requirement for quality and machines.

2. Peanut oil making machine specification:

Our products are edible oil press machine, edible oil solvent extraction machine and edible oil refining machine.

We can supply semicontinuous peanut oil makig machine for 20-30T/D and continuou sets of cooking oil making machine for 30-2000T/D. By the customers requirement we can provide cooking oil press machine,cooking oil prepress machine, cooking oil solvent extraction machine and cooking oil refining machine.Any part of this edible oil producing line can be provided by us.

On the first stage of peanut oil making machine,the seeds are going through cleaning, hulling, crushing, flaking, softening, cooking, pressing and filtering. For this process different types of pressing systems are used, according to a volume of output you need and also according to a type of seeds you are using to get certain oil. The oil pressing system as a rule contains a cleaning sieve, screw elevators, a cooker, a presser, a filter and a refiner. It all depends on a model and design, which different companies can provide you. All seeds are going to a cleaning sector and after step by step to each mentioned sector to be ready for a next stage.

The second stage of peanut oil making machine includes extracting, removing the solvent nature, evaporating, stripping and solvent recycling. Extraction process is the process, which means the separation oil from seeds. The pre-processed seeds are treated in a multistage counter current process with solvent. Then oil and solvent are separated by distillation. The solvent going into the extraction recycle process and the crude oil is ready for a next step. This process will keep production safety and provides a good quality.

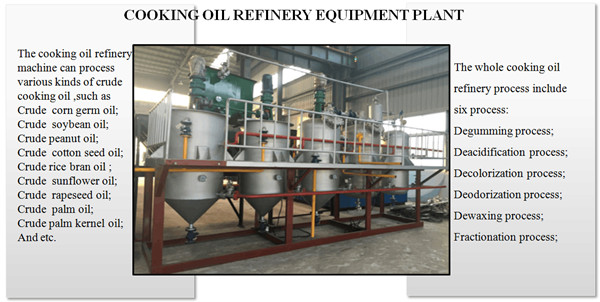

The last stage of peanut oil making machine provides degumming, discoloring, deodorization, removing wax, fractionation etc. De-waxing section is optional. On the stage of degumming the oil separated from sand, after which it gets to be free from free-fatty acids and color pigments. Then the smell and odor are removed from the oil, because many seeds have special odors and smells, which many people don't like. So, that will allow getting a high quality production of oil.

3. Customers

We have customers from all over the world like Uzbekistan, Kyrghizstan, Kazakhstan,and Canada, Chile, Argentina,Ethiopia, Zambia,Nigeria, Russia, Turkey, more than 30 countries and areas.

Contact information:

Skype:sophia.zang1

Mobile:+86 13526627860

Phone:+86-371-5677 1823

Website:www.doingoilmachine.com

E-mail: oilmachine@doingoilmachine.com

| Payment Terms: | T/T |

|---|---|