| Model: | - |

|---|---|

| Brand: | YIZE MOULD |

| Origin: | - |

| Category: | Services / Designing, Processing, Custom Made / Metallic Processing |

| Label: | plastic mould parts , custom precisionmold , high precision molds |

| Price: |

-

|

| Min. Order: | 1 pc |

| Last Online:24 Jul, 2017 |

Dongguan injection molding manufacturer provides plastic mold parts

yizemould921108

product details

| Product name | precision plastic mould parts |

| Material | imported material:SKD11,SKH9,SKH51,SKH55,high-speed steel,special material can customize |

| Size | custom |

| Grinding precision | 0.001mm |

| EDM precision | 0.002mm |

| Grinding angle clearness | 0.002mm |

| Surface roughness for EDM | Ra 0.04 |

| MOQ | 1 PC |

| QC report | include |

| Delivery type | DHL express |

| Delivery time | 10 days |

| Packaging type | paper of box |

| payment term | T/T,30% deposit,70% balance after receiving parts |

Business steps

1.Sample/Drawing We need your detail require clearly.

↓

2.Negotiation Material,price,delivery time,payment term ,etc.

↓

3.Place order According your own design or choose our design.

↓

4.Mould design We will communicate&exchange the opinion with you during making drawing.

↓

5.Tooling mould After customer approve the mould design will start making mould.

↓

6.Mould process Provide photos for customer show them tooling process.

↓

7.Sample confirm Send you sample for confoirm it ,if not satisfied by customer.we modify mould .

↓

8.Delivery mould Delivery mould after customer approve sample and arrange shipment

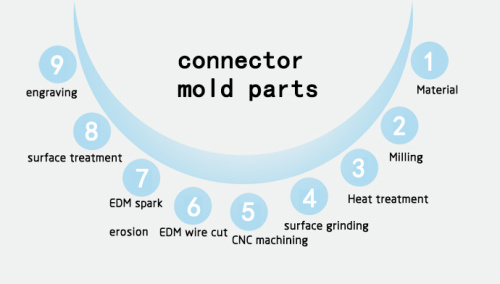

The following processes are used:

1.CNC milling

2.EDM spark

3.Wire cut

4.EDM

5.Grinding

6.Drilling

7.Heat treatment

our service

· We will keep tracing of every process in the manufacturing from the begining to the end.

· Every parts quality checked & cleaned before packing.

· Before parts delivery, clients could send one QC or point the third party to check the quality.

· After the delivery, we will keep tracing of the mould parts quality and we will try our best to help the clients when the problems happen.

contact with us